Securing spikes in pre-existing loosened spike cavities in railroad ties

a technology of pre-existing loosened spikes and rail ties, which is applied in the direction of track superstructure, construction, and way, etc., can solve the problems of shortening the expected life, affecting the service life of rail ties, so as to achieve the effect of limited labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

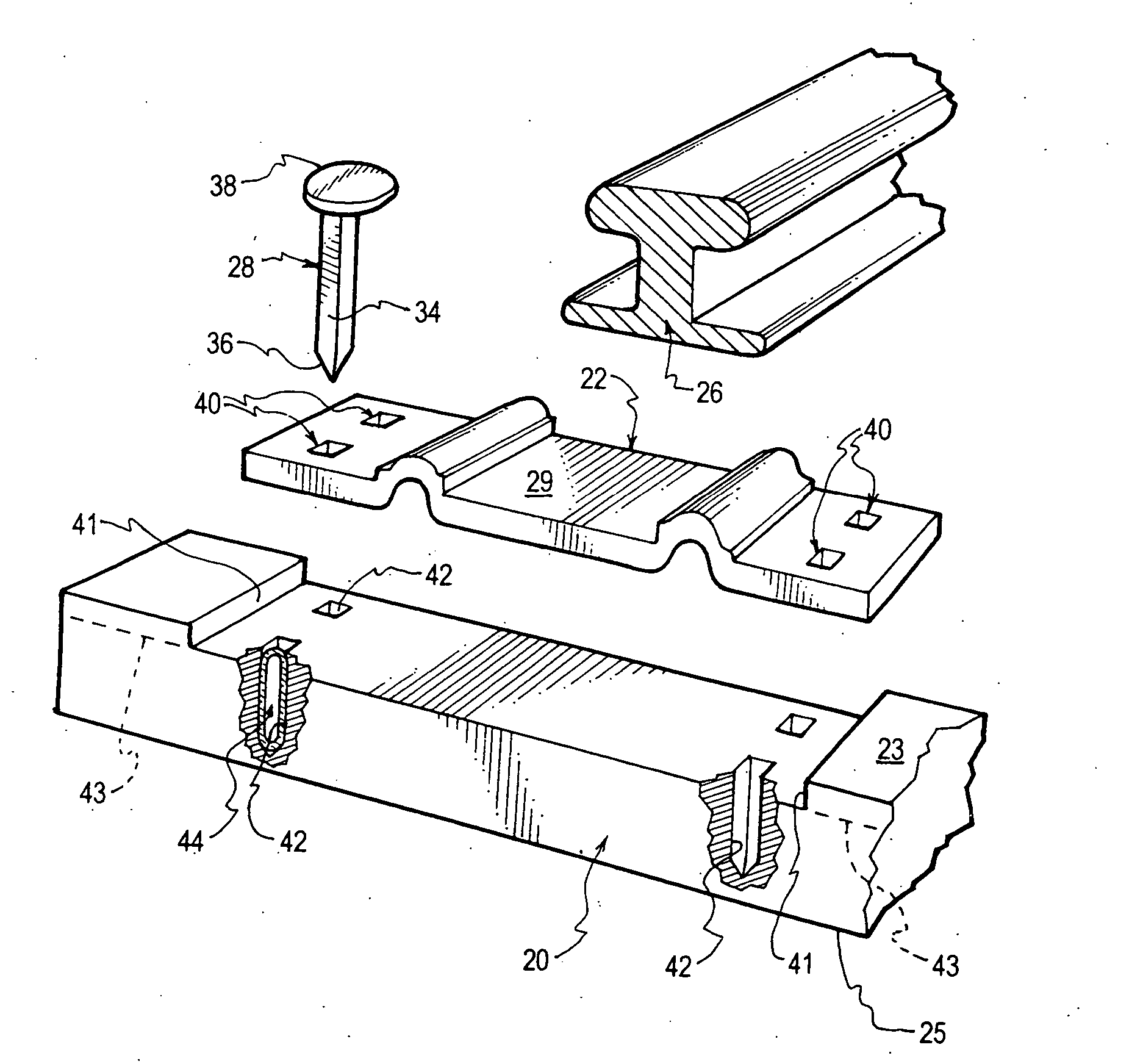

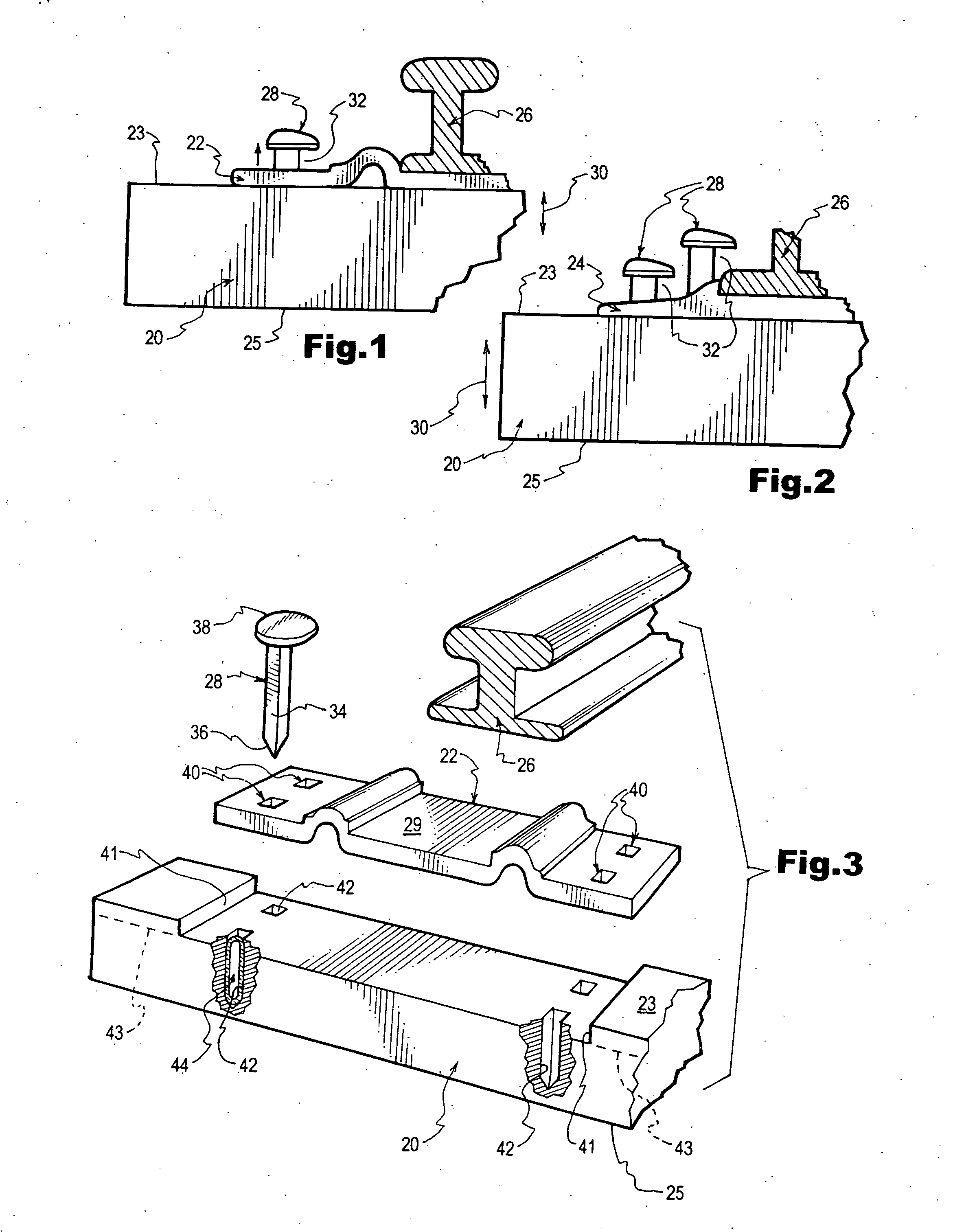

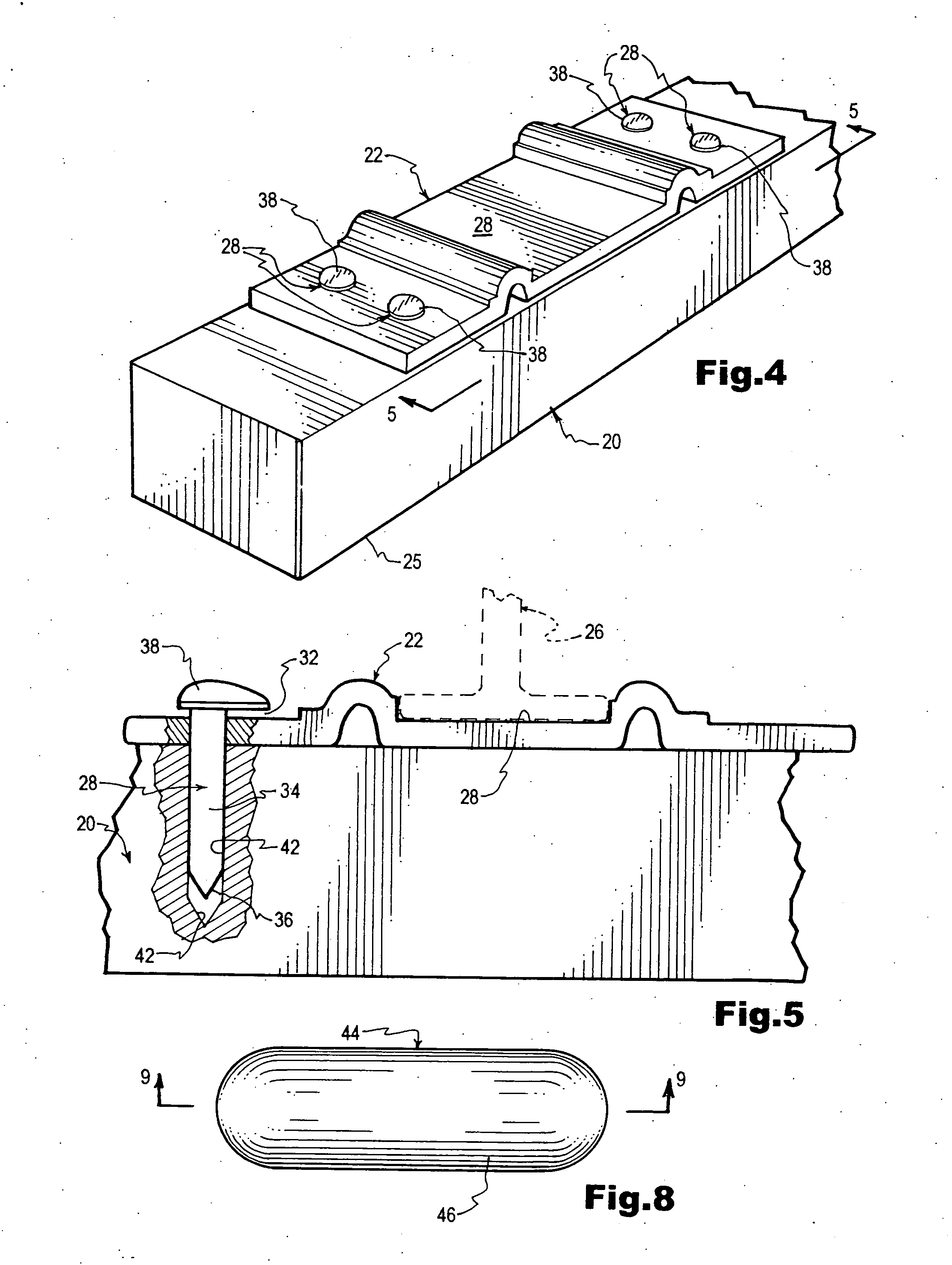

[0030] Reference is now made to the drawings wherein like numerals are used to designate like parts throughout. As set forth in some detail above, rail deflection from the weight of railroad cars, which is maximum when two car wheels are directly above a given railroad tie, as well as vibration and other loads imposed, tend to loosen spikes. Loosened spikes tend to allow tie plates to undesirably move up and down and, with some tie plates, also allow vertical displacement or load chatter between a railroad rail and an associated tie plate. Loosening of railroad spikes creates danger of rail malfunction with the possibility of railroad car or locomotive derailment. It also sometimes allows moisture to infiltrate into the associated spike cavity, which, with wooden railroad ties, can cause rot within the spike cavity further weakening the grasp between spike and the spike cavity. This invention addresses the problem of re-introducing railroad spikes into a fully inserted position in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com