Locking Latch for Telescoping Tripod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

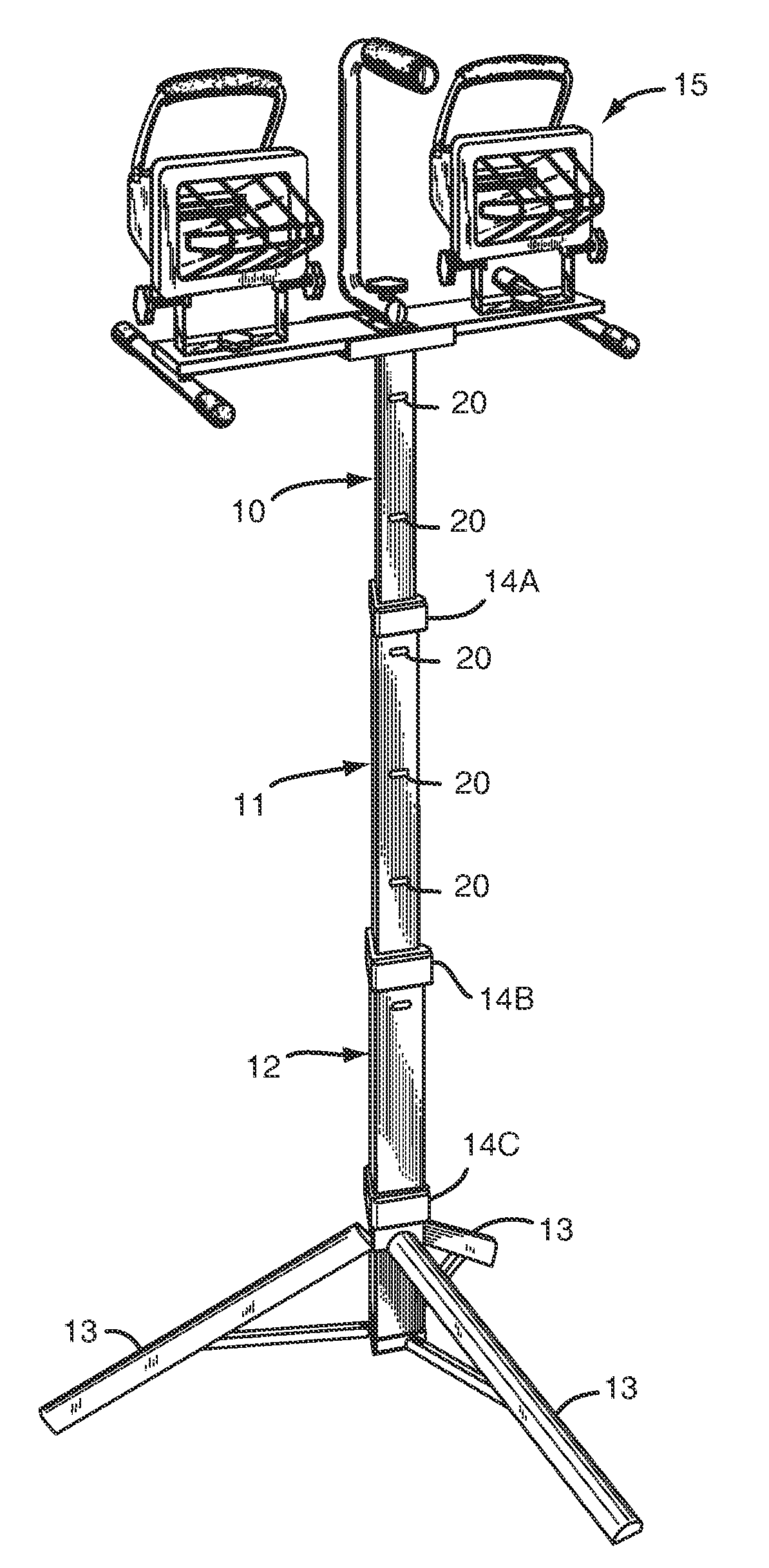

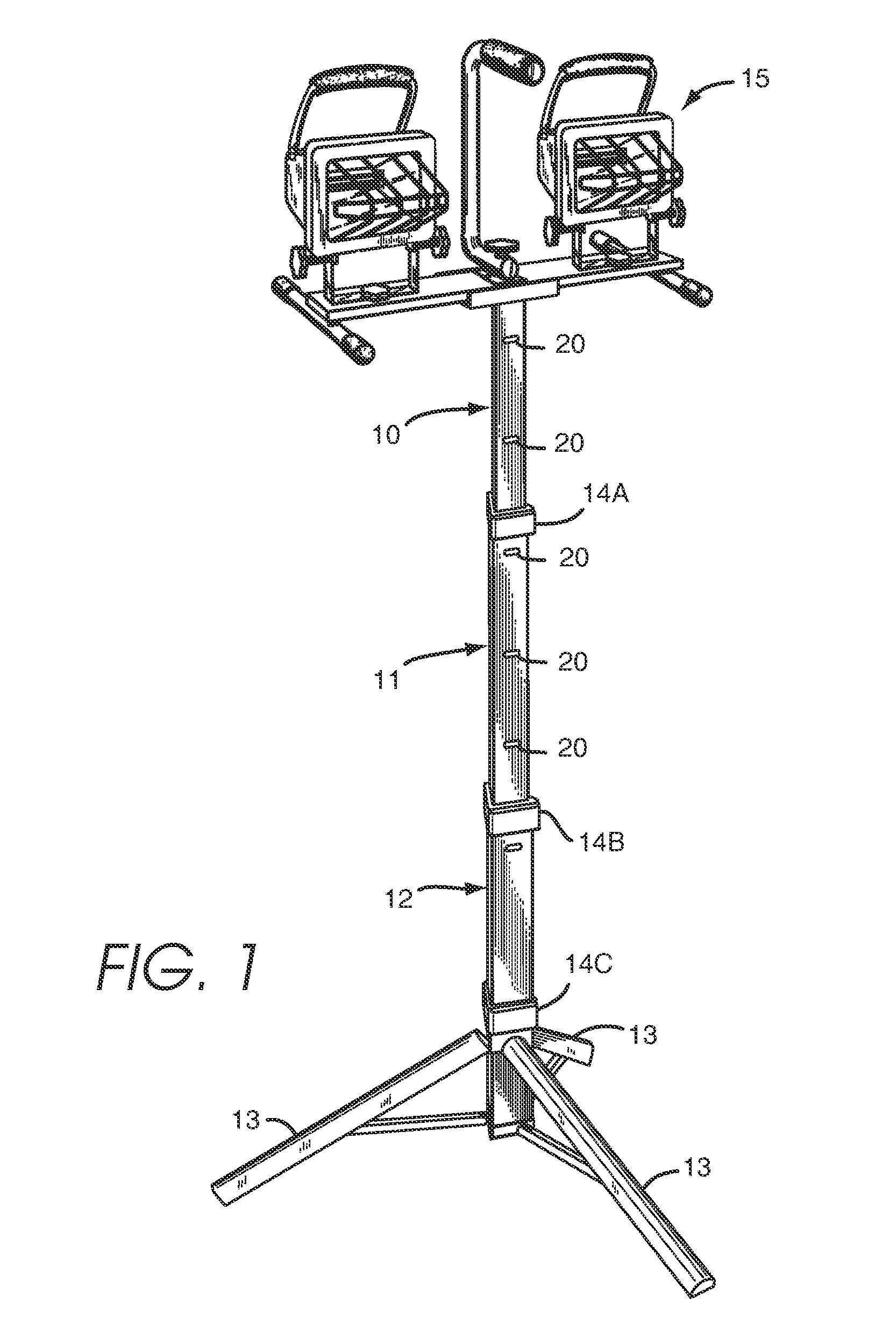

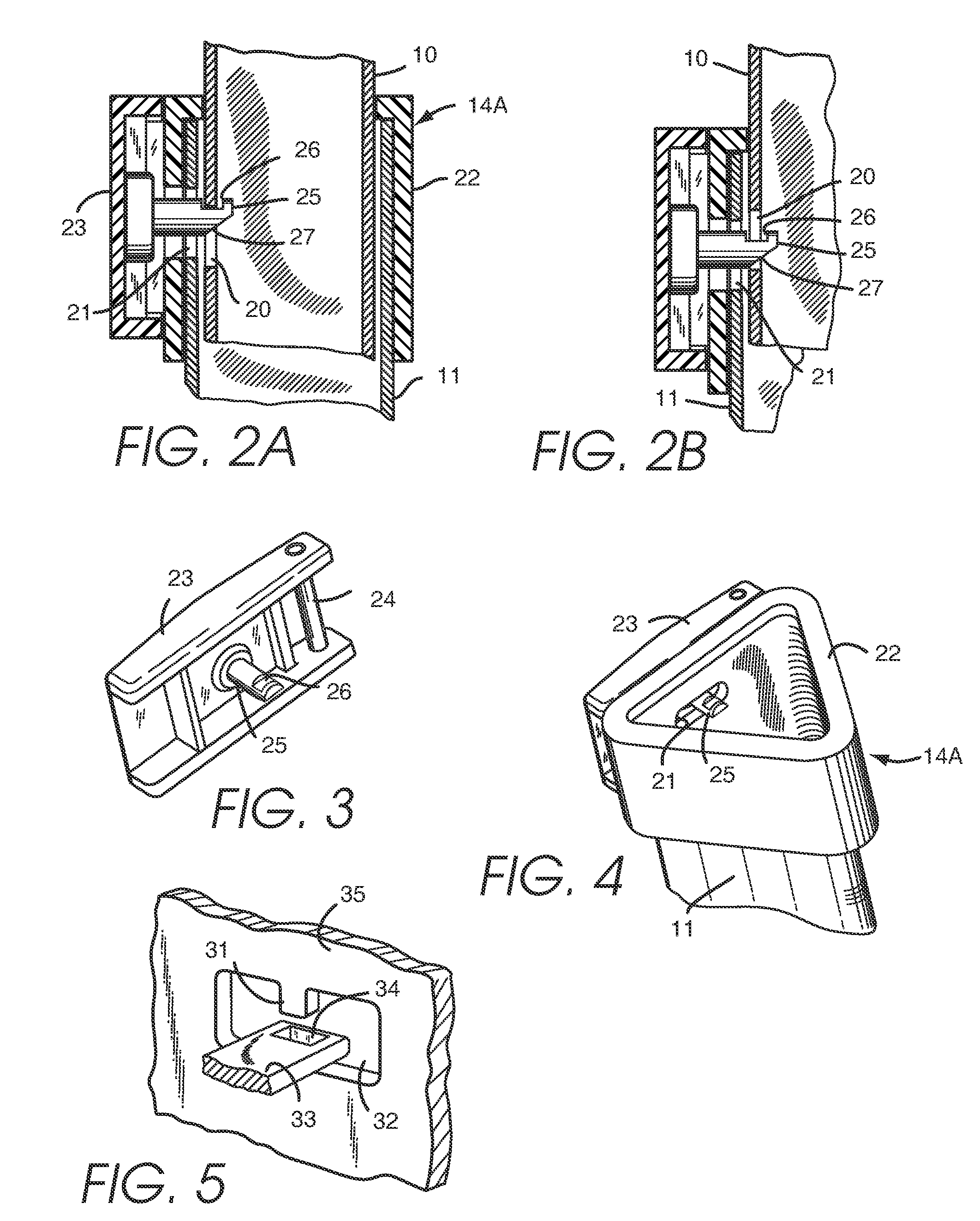

[0014]FIG. 1 shows an extendable support stand, commonly referred to as an extendable tripod, supporting a dual-head halogen worklight 10. The tripod includes an elongate base section 11 and two extendable elongate sections 12 and 13. The sections 11, 12, 13 are in telescoping relation with one another such that section 10 retracts into section 11, which retracts into base section 12. The sections 11 and 12 may be extended by variable amounts to adjust the height of the tripod. The tripod also includes a plurality of deployable legs 13 for supporting the tripod on the ground or other work surface. Between each pair of adjacent sections is a latching mechanism 14A and 14B for securely holding the extended sections in their extended disposition. The latching mechanism is releasable to permit the user to retract the tripod sections as desired. The tripod of FIG. 1 also includes a latching mechanism 14C that slides along the base section 12 and locks the legs 13 into a retracted positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com