Precast stair tread with bolts

a precast and bolt technology, applied in the direction of treads, flooring, construction, etc., can solve the problems that the strength and integrity of the product cannot be affected by the reduction in weight, and the construction industry is particularly affected by the increase in fuel costs, so as to achieve satisfactory structural integrity and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In describing a preferred embodiment of the invention illustrated in the drawings, specific terminology will be resorted to for the sake of clarity. However, the invention is not intended to be limited to the specific terms so selected, and it is to be understood that each specific term includes all technical equivalents which operate in a similar manner to accomplish a similar purpose.

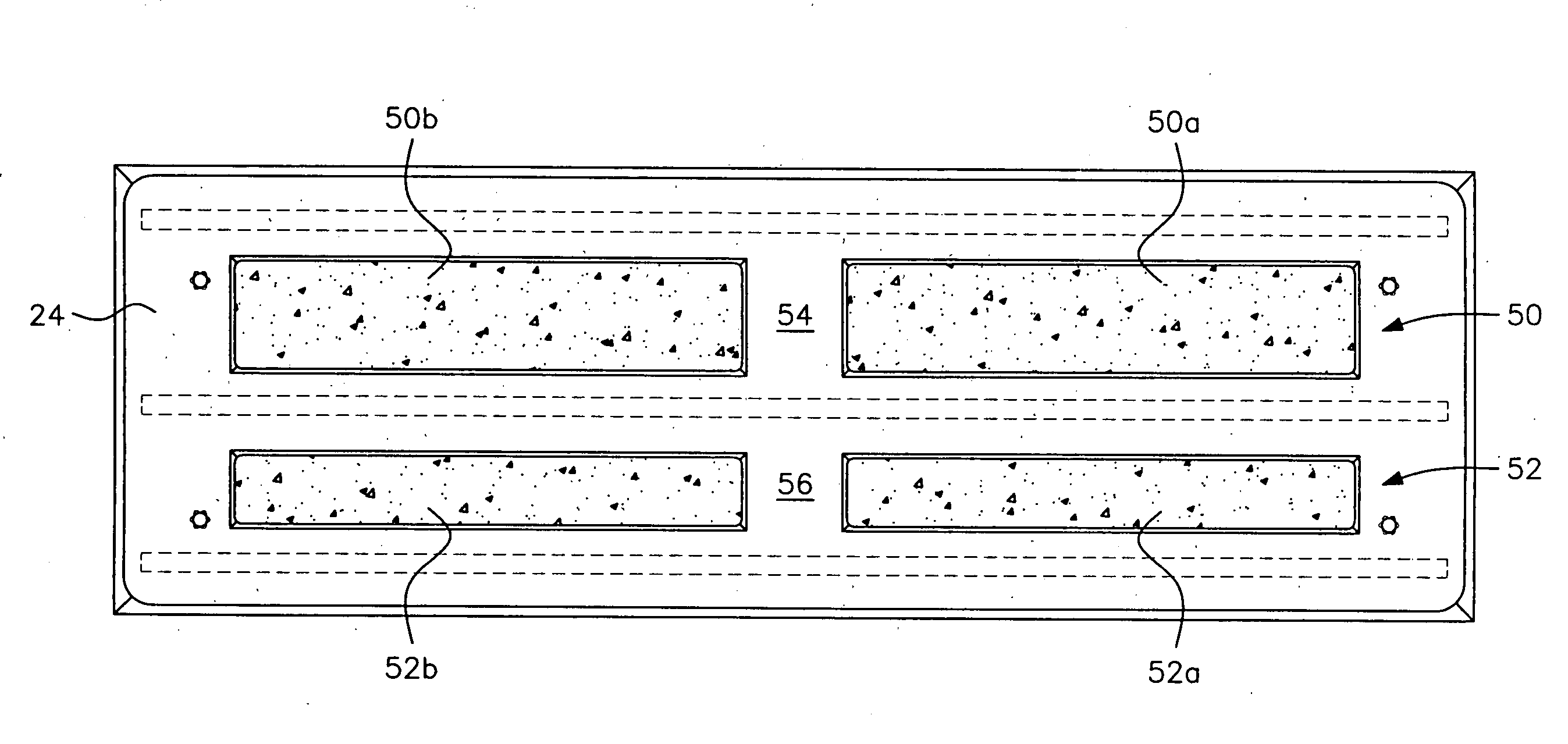

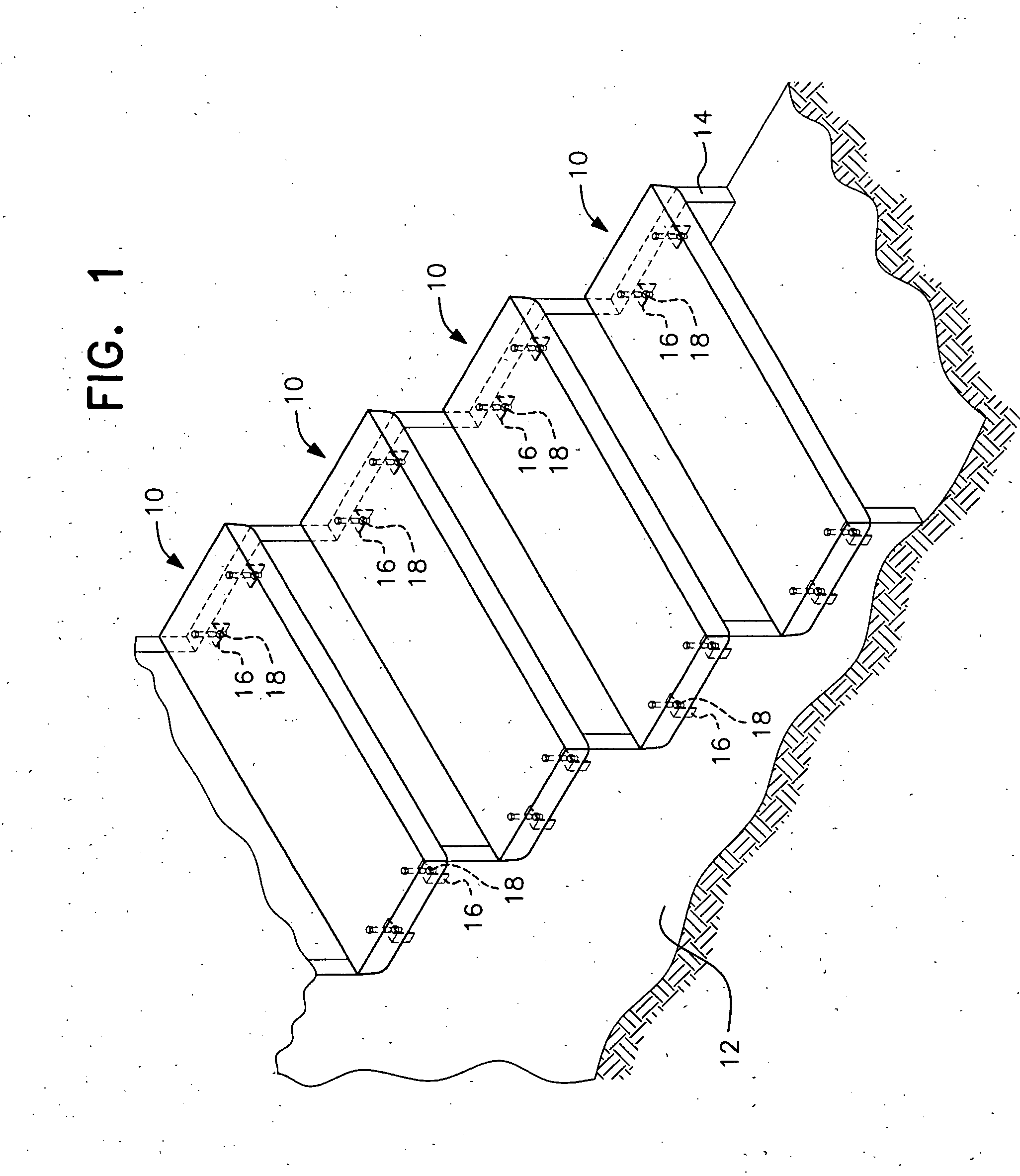

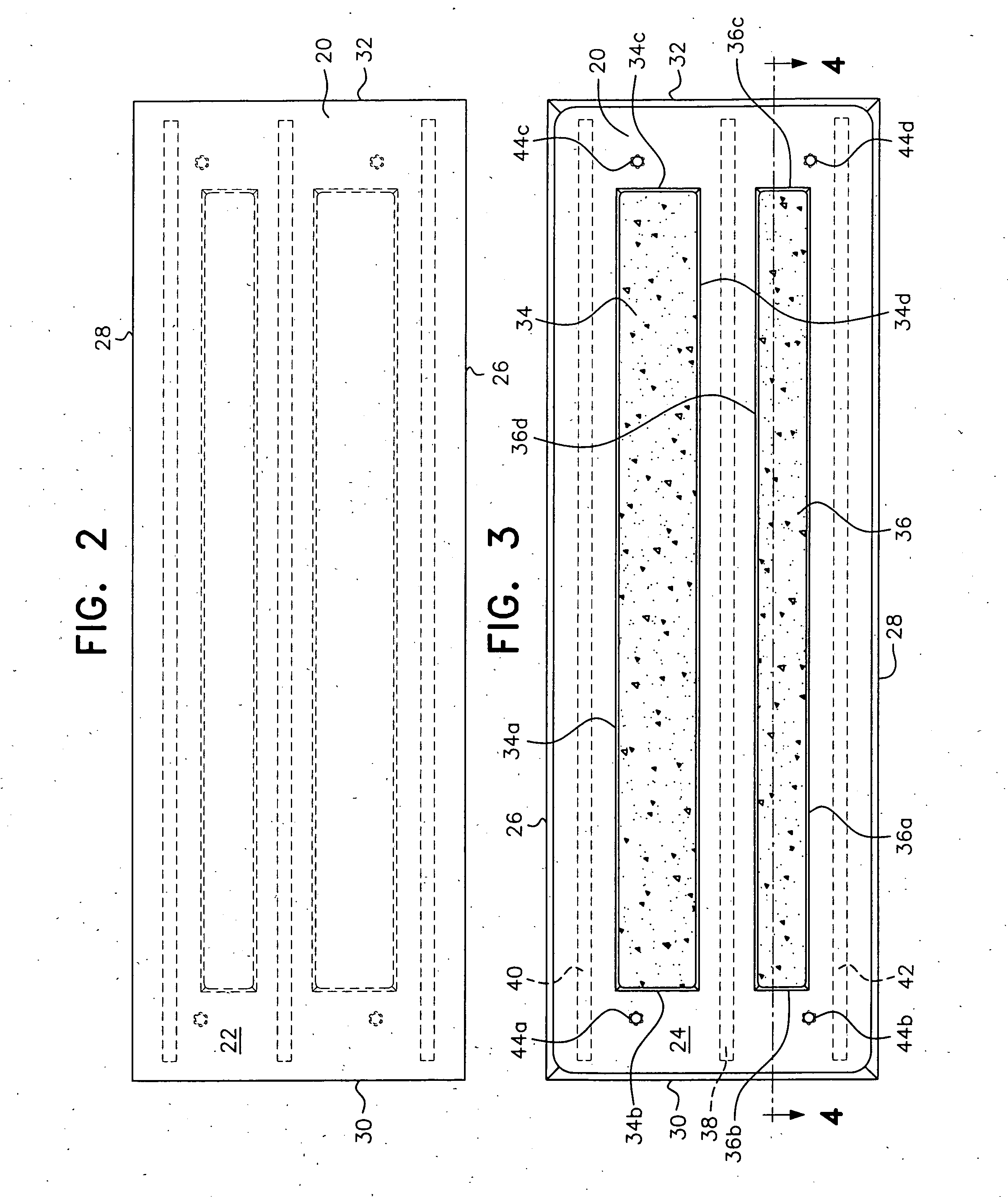

[0027] With reference to the drawings, in general, and to FIGS. 2 through 5, in particular, a precast stair tread embodying the teachings of the subject invention is generally designated as 10.

[0028] With reference to its orientation in FIG. 1, the stair tread is shown in its position of use supported by two spaced apart stair frames 12, 14. The stair frames have been assembled at a construction site for enabling transit between two floors by an in situ formed staircase.

[0029] A plurality of precast stair treads 10 of the present invention are transported to the construction site for assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com