Locomotive and rail car braking regeneration and propulsion system and method

a technology for locomotives and rail cars, applied in the field of locomotives, can solve the problems of polluting the environment, diesel locomotives consuming a lot of diesel fuel,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

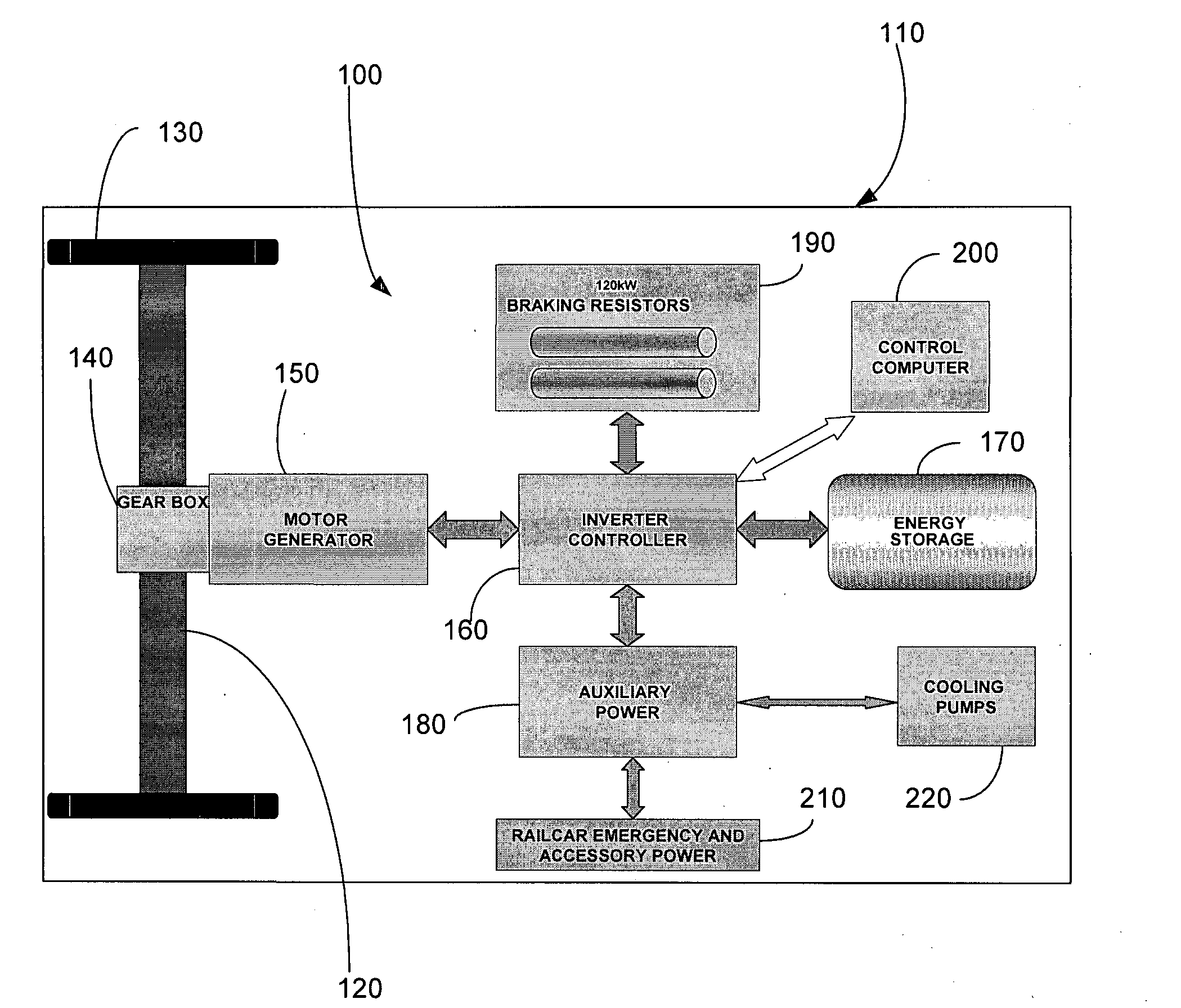

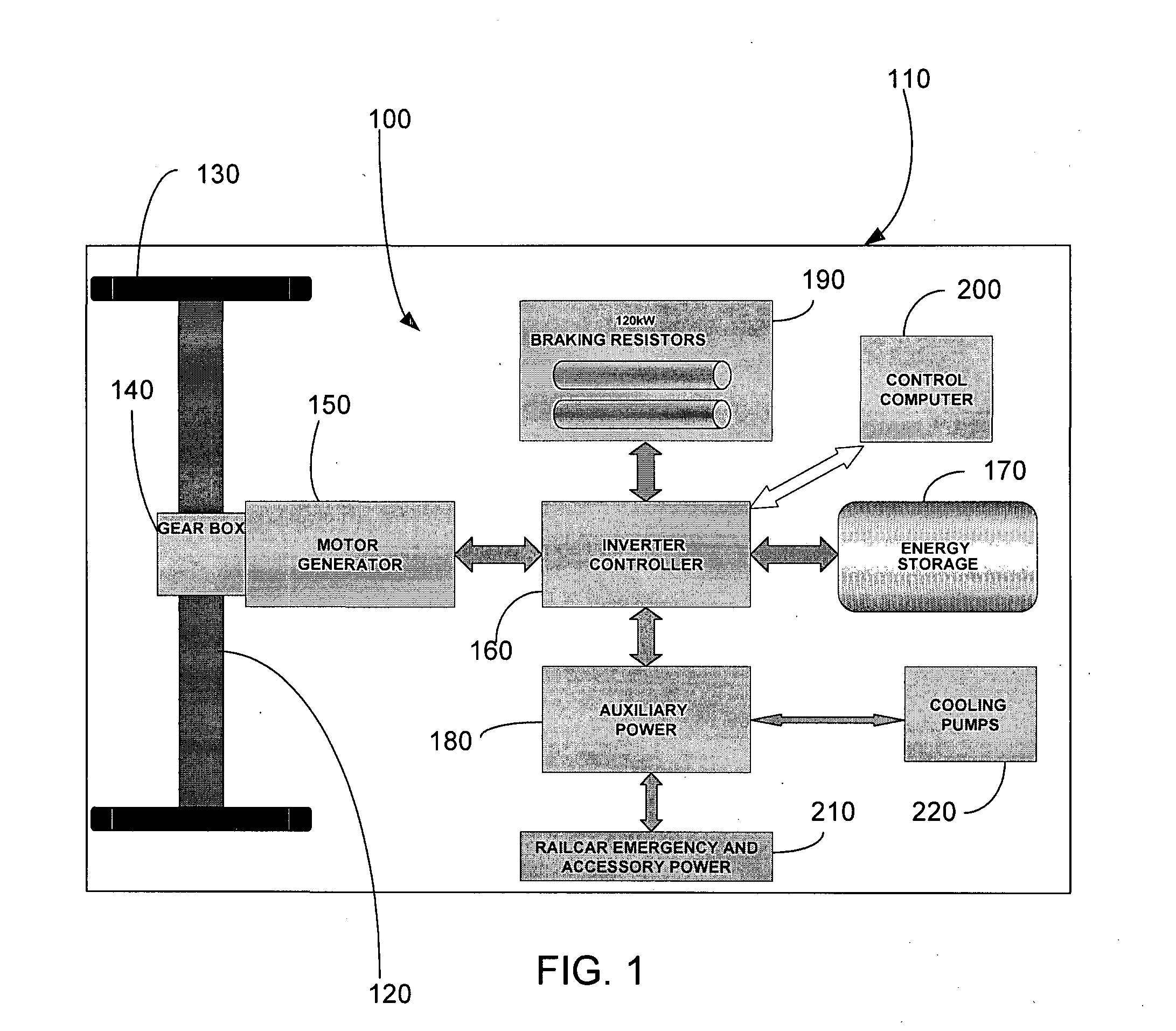

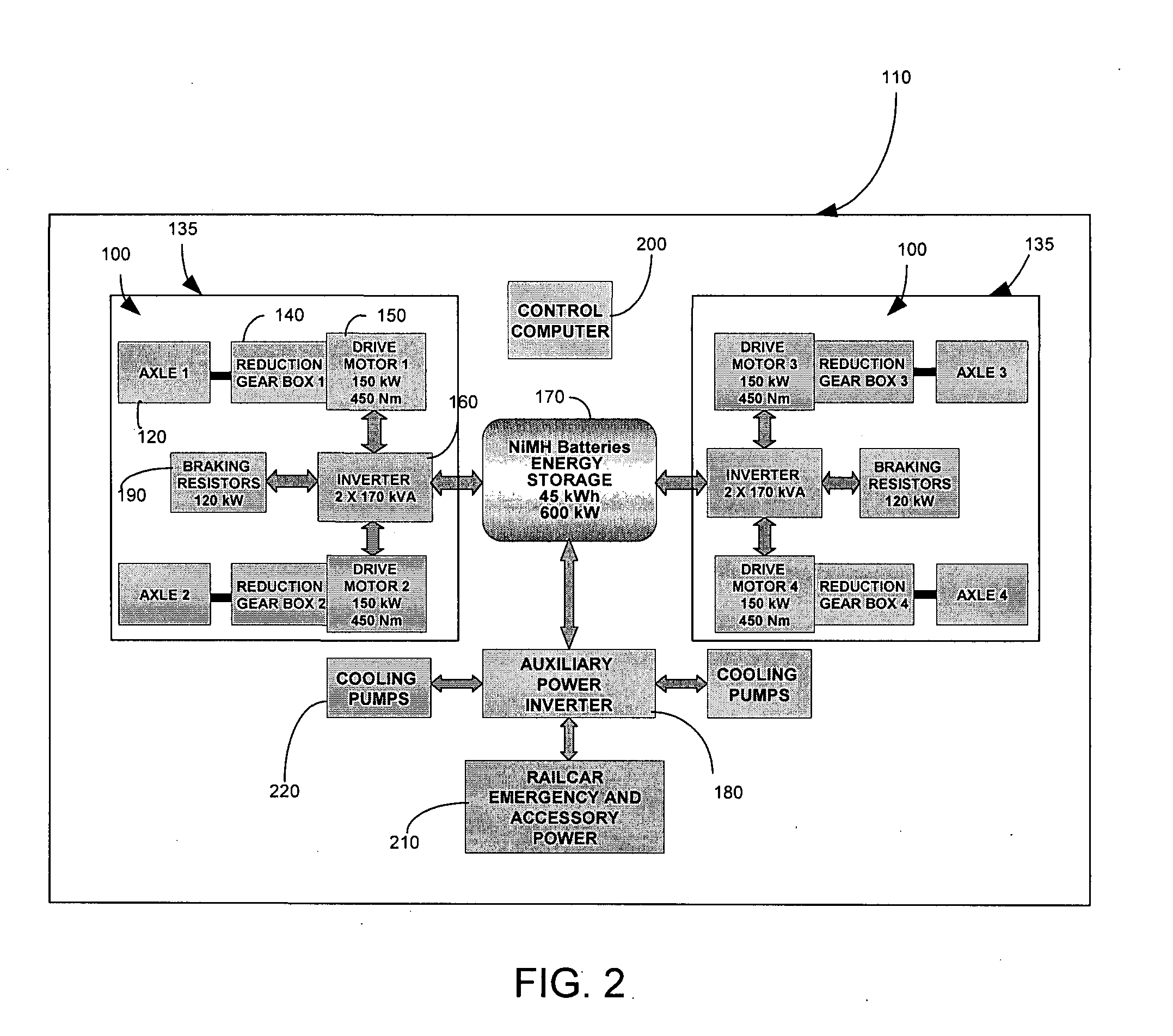

[0021]With reference to FIGS. 1 and 2, an axle-mounted braking regeneration energy storage and acceleration system 100 for a passive rail car 110 will be described. As used herein, “passive rail car” refers to rail car primarily propelled (e.g., pulled, pushed) by a separate driving rail car (e.g., locomotive). A passive rail car has no primary power unit for the conversion of chemical fuel into electric or kinetic energy used to propel the vehicle. A rail car is defined as a flange wheeled vehicle where the wheels roll on and are guided by rails on a road bed also known as a railroad track. Although the braking regeneration system 100 will be described as being axle-mounted, in alternative embodiments, the braking regeneration system 100 is mounted to other and / or additional structures of a passive rail car.

[0022]In the embodiment shown, the passive rail car 110 is a Comet V commuter rail car including multiple axles 120 with wheels 130 on opposite ends of the axles 120 and a frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com