Non-woven structures and methods of making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

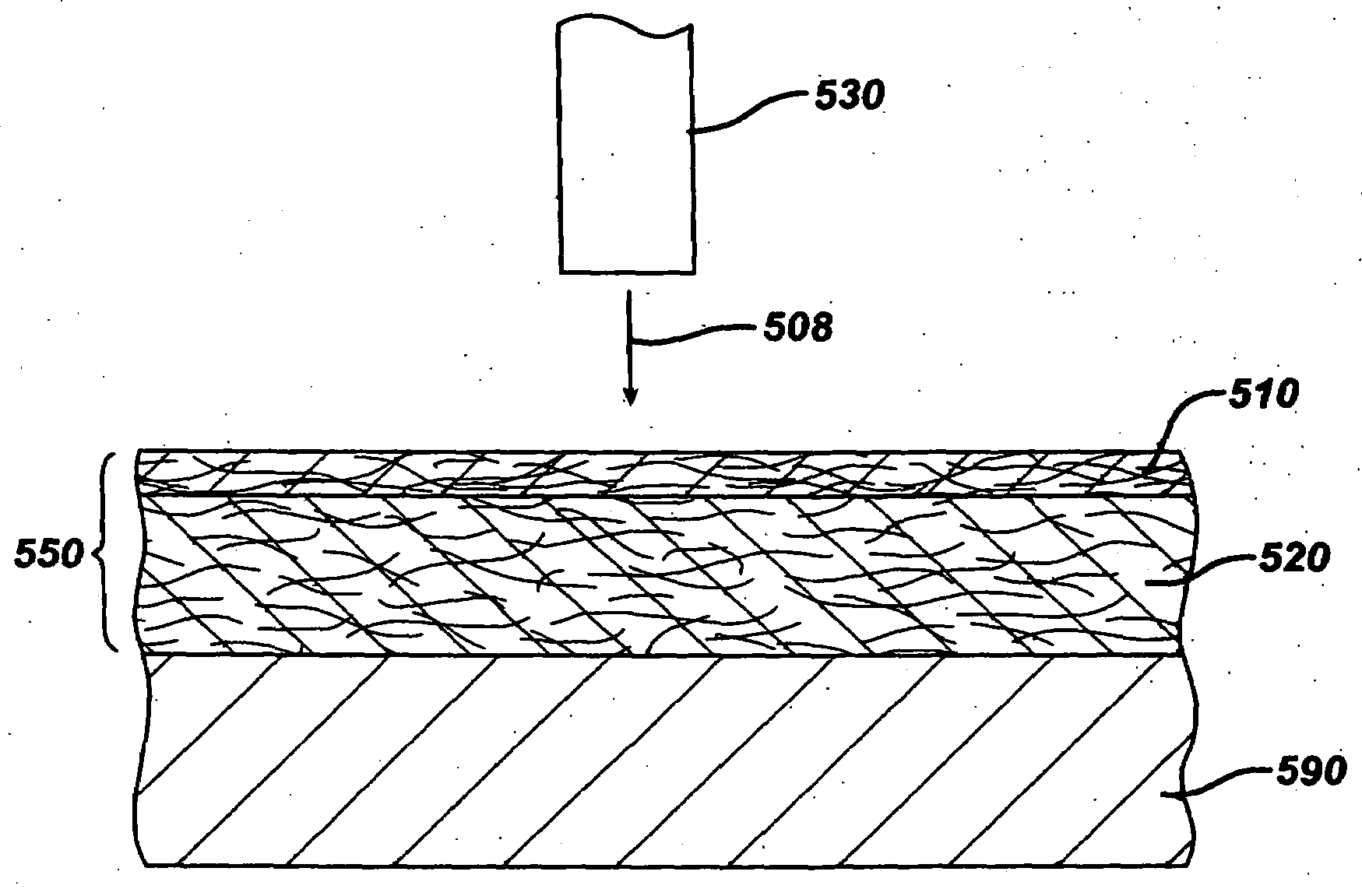

[0075]In each of the following examples, a target web was placed on a 80-mesh metal screen forming surface, on a rotating cylindrical drum. The target web consisted of a layer of fibrous material and a fluid-permeable anchoring layer. The fluid permeable anchoring layer used was a 12 gsm layer of spun-bonded polypropylene, commercially available from BBA Fiberweb. The fibrous material was a blend of 70% rayon fibers and 30% polyester fibers of varying basis weight. The drum was rotated to move the layer of fibers at a linear speed of 100 fpm. The jets were oriented to expel a stream of pressurized water to strike the target web perpendicularly to the target web. The jets were arranged in a row of jets spaced to a jet density of 30 jets / inch. All fibrous layers were subject to an initial stabilization treatment in which water was urged though each of a number of 0.005-inch diameter jets at 600 psi to loosely bond the fibers prior to entangling with the spun-bonded polypropylene. The ...

example 1a

[0089]The spunbond material layer as placed “under” the fibrous layer (i.e., the fibrous layer was positioned between the jets and the fluid-permeable anchoring layer). The jet pressure was 1500 psi. The web was moved across the jets 4 times. The resulting layered, composite material had a lamination strength (LSV) of 25 grams (g.), a thickness of 0.77 mm, a basis weight of 85 gsm, a density of 0.11 g / cc, and a drapeability of 7.9 gsm / g.

example 1b

[0090]The spunbond material layer as placed under the fibrous layer. The jet pressure was 1500 psi. The web was moved across the jets 8 times. The resulting layered, composite material had a lamination strength of 65 grams (g.), a thickness of 0.73 mm, a basis weight of 88 gsm, a density of 0.12 g / cc, and a drapeability of 8.6 gsm / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com