Laminated sheet material and sheet material stuck on body

A sticking, body technology, applied in the direction of layered products, cosmetic preparations, chemical instruments and methods, etc., can solve the problems of hard texture, poor adhesion, difficult lamination, etc., to achieve high lamination strength, inhibit volatilization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

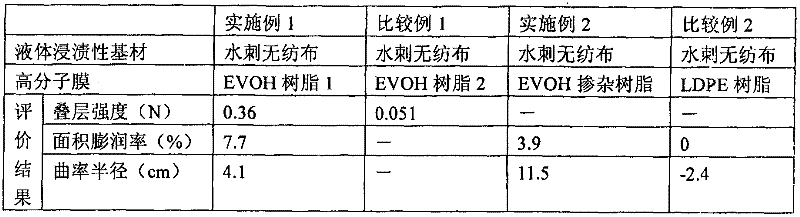

[0097] In spunlaced nonwoven (polyethylene terephthalate (PET) core / polyethylene (PE) sheath: rayon = 50:50, weight per unit area 80g / m 2 ) at 250°C, extrude EVOH resin 1 (EVAL G 156B (EVAL G 156B) (Kuraray Co., Ltd.), MFR 15g / 10min) with a single-layer T-die to make a film thickness of 15μm. Laminate sheet A of the present invention.

[0098] The laminated sheet was evaluated according to the above-mentioned methods (1-1) to (1-3). The results are shown in Table 1.

Embodiment 2

[0103] In Example 1, instead of EVOH resin 1, EVOH blended (blend) resin (EVAL G 156B: polyolefin resin BPO-10 (Kuraray) = 6:4) was used, except that it was the same as Example 1 Laminate sheet C is produced.

[0104] The laminated sheet was evaluated according to the above-mentioned methods (1-2) and (1-3). The results are shown in Table 1.

Embodiment 3

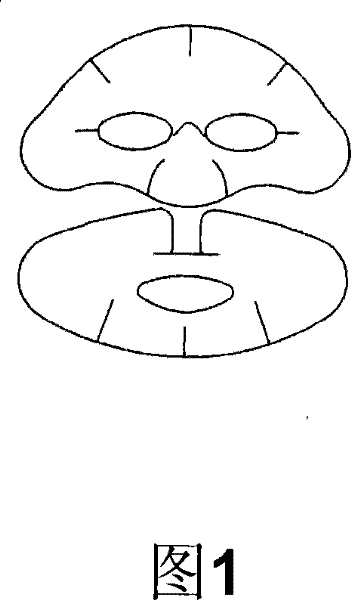

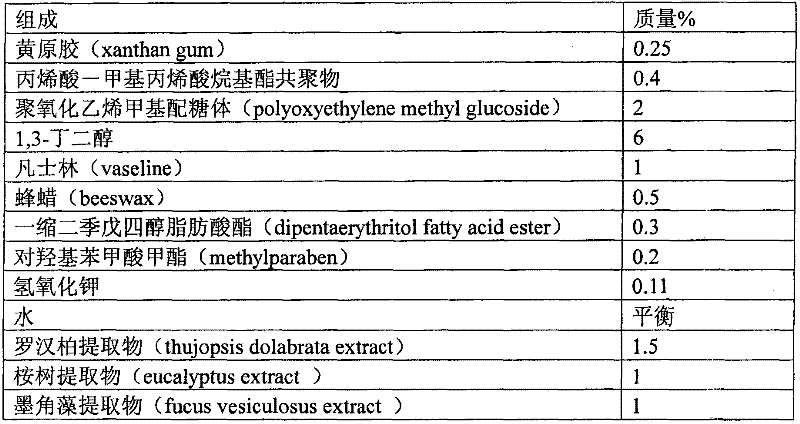

[0111] Such as figure 1 As shown, the laminated sheet A made according to Example 1 was cut into a facial mask model, and 25 g of the impregnating liquid of the composition described in Table 2 was uniformly impregnated on the non-woven fabric side with a dropper (Spuit) to obtain a body mask. Additional sheet A-1. This body sticking sheet A-1 was put into an aluminum pillow, and the aluminum pillow was sealed and closed with an impulse sealer. This body sticking sheet A-1 was evaluated according to the method (2-1) above. The evaluation results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com