Non-woven structures and methods of making the same

a non-woven structure and non-woven technology, applied in the field of layers and composite materials, can solve the problems of lack of cushiony feel, lack of visible patterns of conventional drapeable materials, deficiency in one or more of abrasion resistance, lamination strength, bulkiness or other properties, etc., and achieve high drapeability, low density properties, and high lamination strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

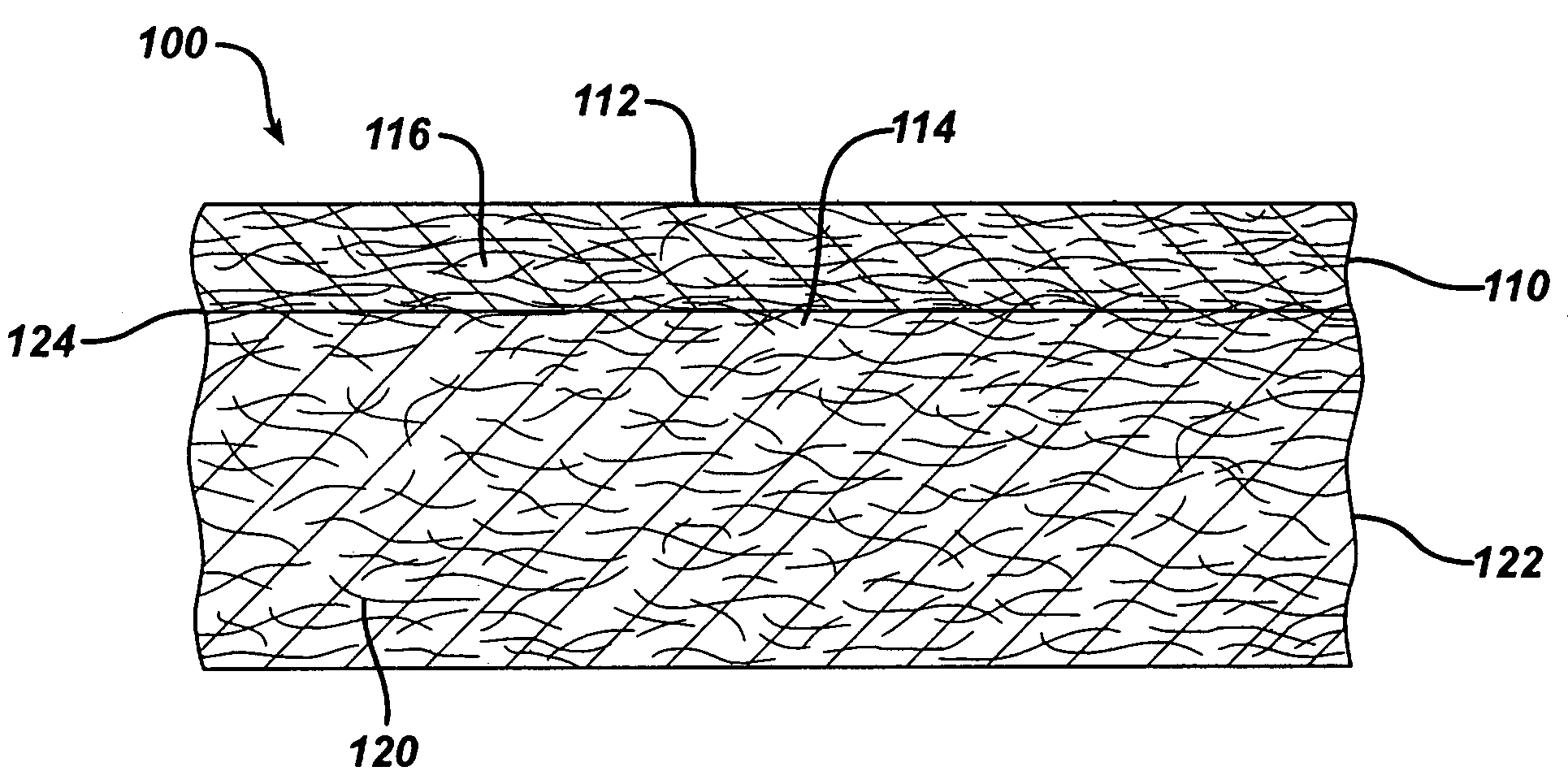

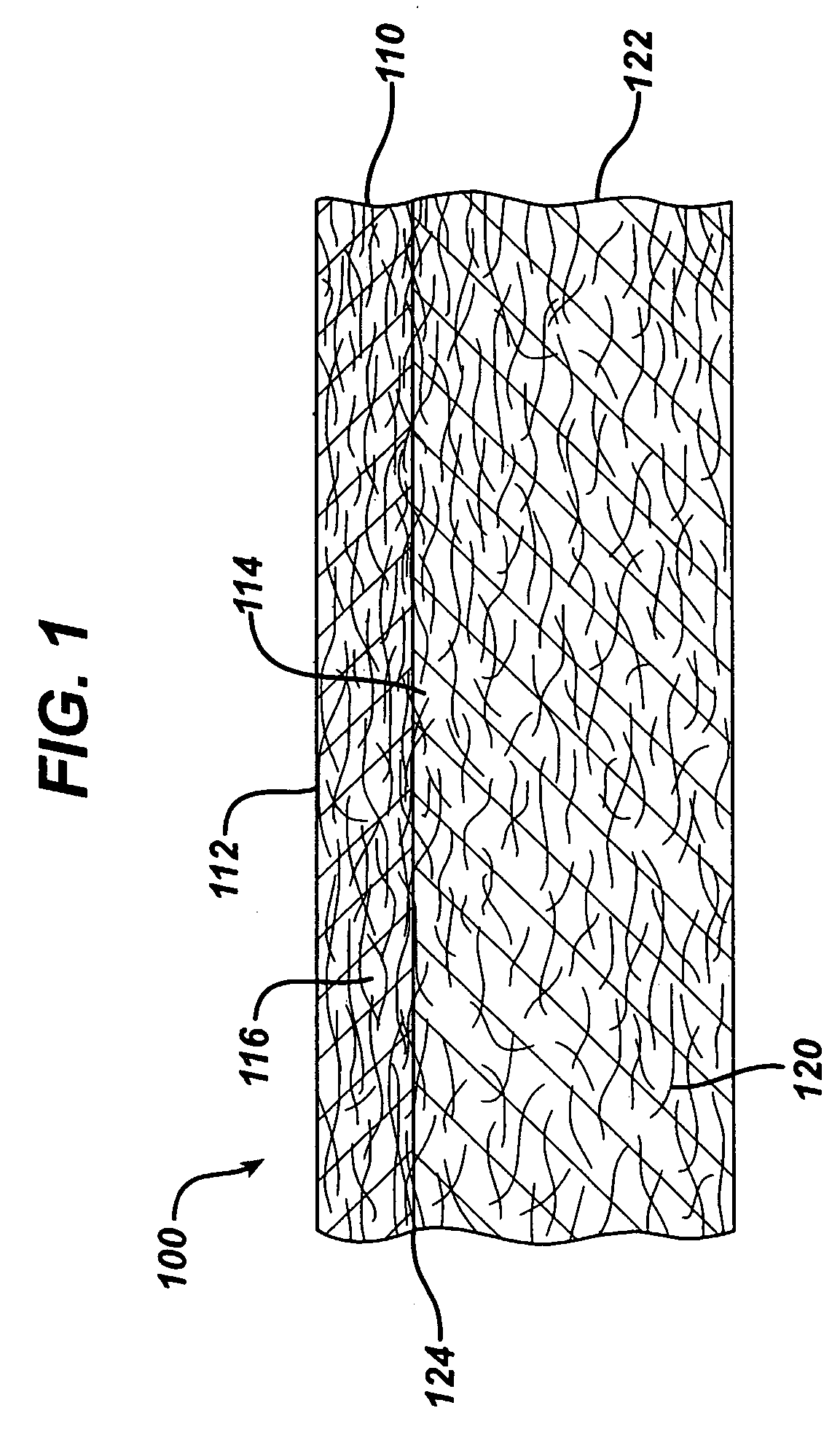

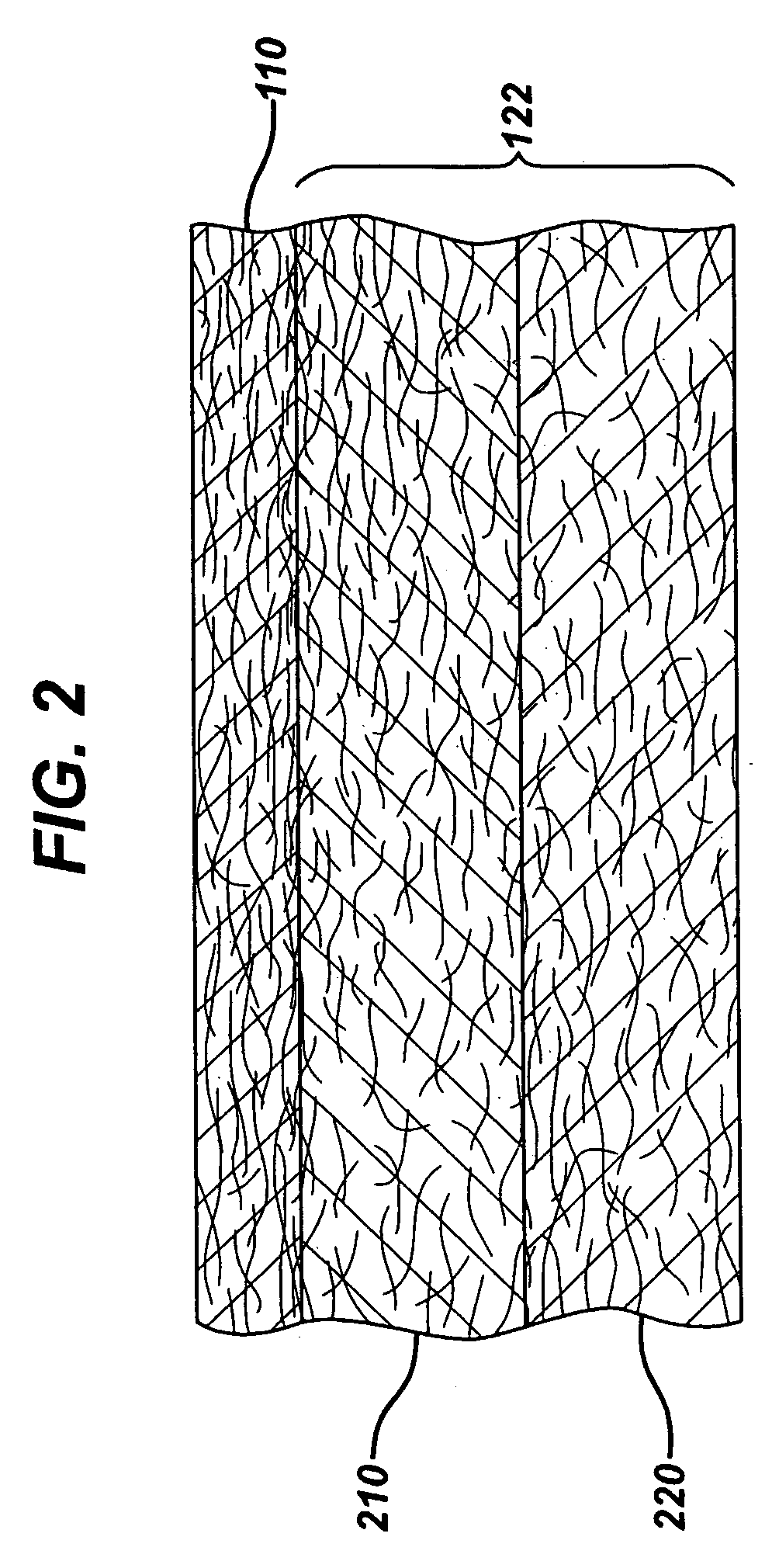

Image

Examples

example 1

[0075]In each of the following examples, a target web was placed on a 80-mesh metal screen forming surface, on a rotating cylindrical drum. The target web consisted of a layer of fibrous material and a fluid-permeable anchoring layer. The fluid permeable anchoring layer used was a 12 gsm layer of spun-bonded polypropylene, commercially available from BBA Fiberweb. The fibrous material was a blend of 70% rayon fibers and 30% polyester fibers of varying basis weight. The drum was rotated to move the layer of fibers at a linear speed of 100 fpm. The jets were oriented to expel a stream of pressurized water to strike the target web perpendicularly to the target web. The jets were arranged in a row of jets spaced to a jet density of 30 jets / inch. All fibrous layers were subject to an initial stabilization treatment in which water was urged though each of a number of 0.005-inch diameterjets at 600 psi to loosely bond the fibers prior to entangling with the spun-bonded polypropylene. The d...

example 1a

[0089]The spunbond material layer as placed “under” the fibrous layer (i.e., the fibrous layer was positioned between the jets and the fluid-permeable anchoring layer). The jet pressure was 1500 psi. The web was moved across the jets 4 times. The resulting layered, composite material had a lamination strength (LSV) of 25 grams (g.), a thickness of 0.77 mm, a basis weight of 85 gsm, a density of 0.11 g / cc, and a drapeability of 7.9 gsm / g.

example 1b

[0090]The spunbond material layer as placed under the fibrous layer. The jet pressure was 1500 psi. The web was moved across the jets 8 times. The resulting layered, composite material had a lamination strength of 65 grams (g.), a thickness of 0.73 mm, a basis weight of 88 gsm, a density of 0.12 g / cc, and a drapeability of 8.6 gsm / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com