Environmental rigid blister package

a blister card and packaging technology, applied in the field of retail product display packages, can solve the problems of not allowing the product to be seen from the back side, difficult to compress the size of the blister card to be easily inserted into the trouser pocket, and difficult to reduce the size of the blister card, so as to improve the effective thickness of the flange, simplify the process of re-usability, and simplify the effect of stock keeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

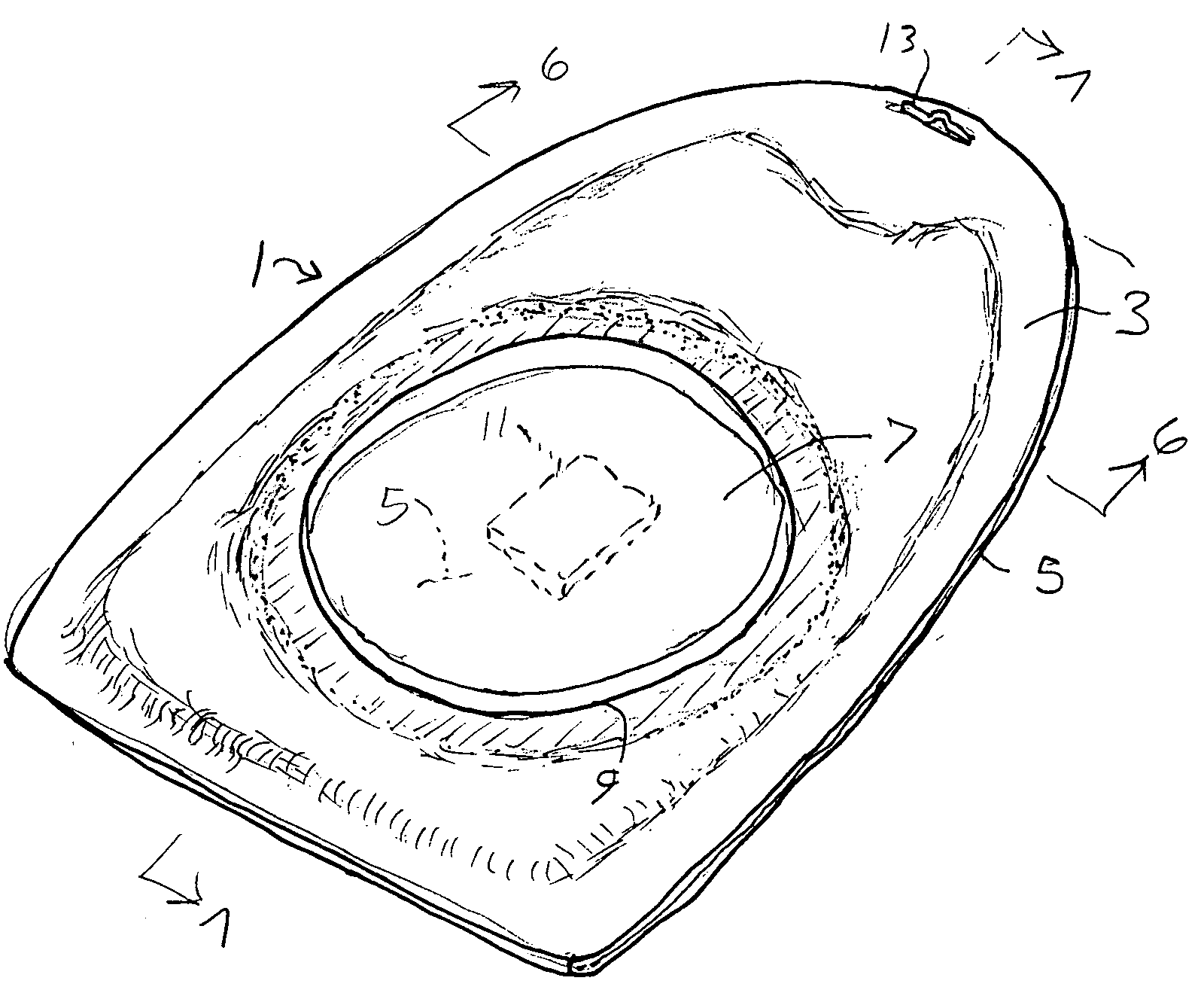

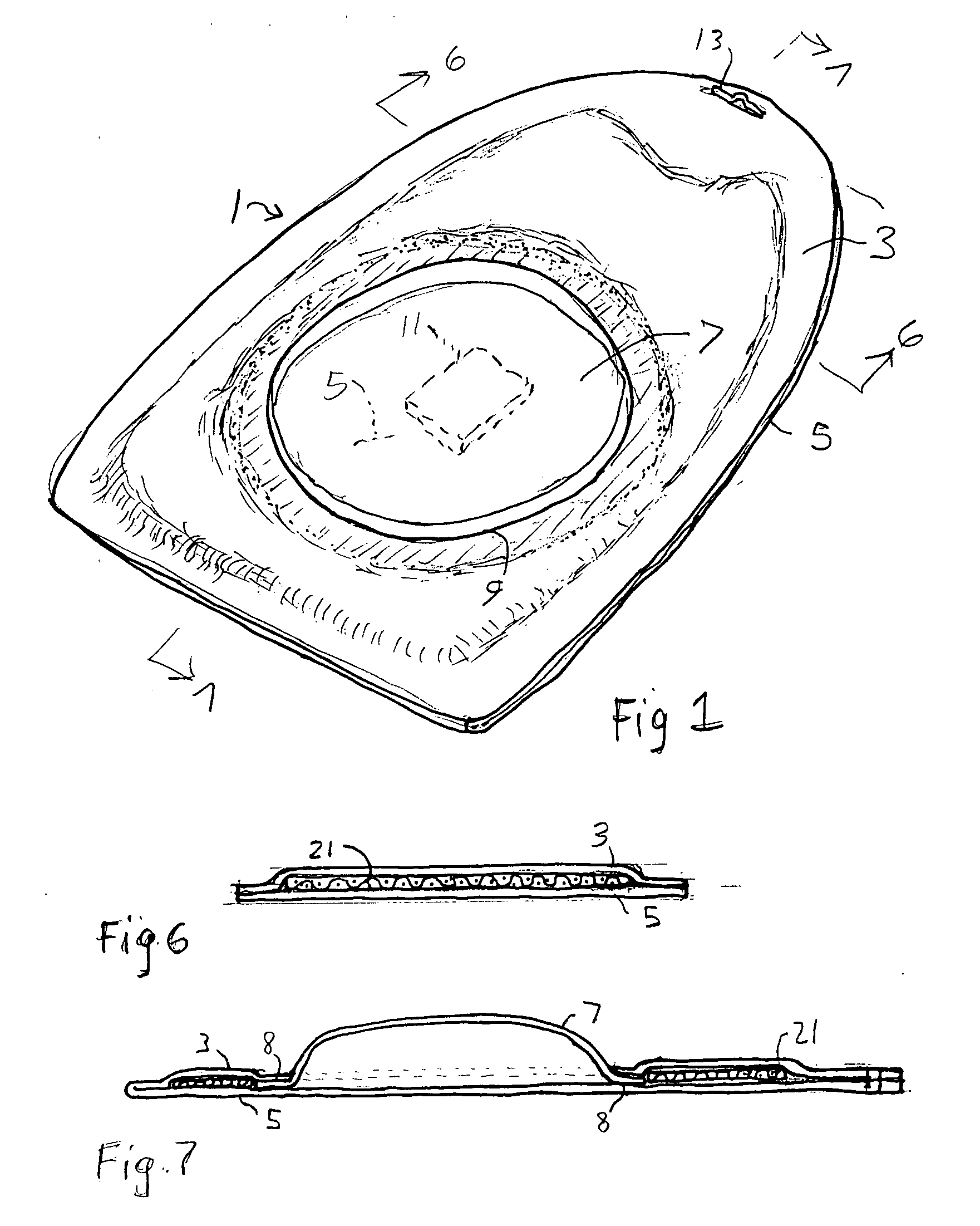

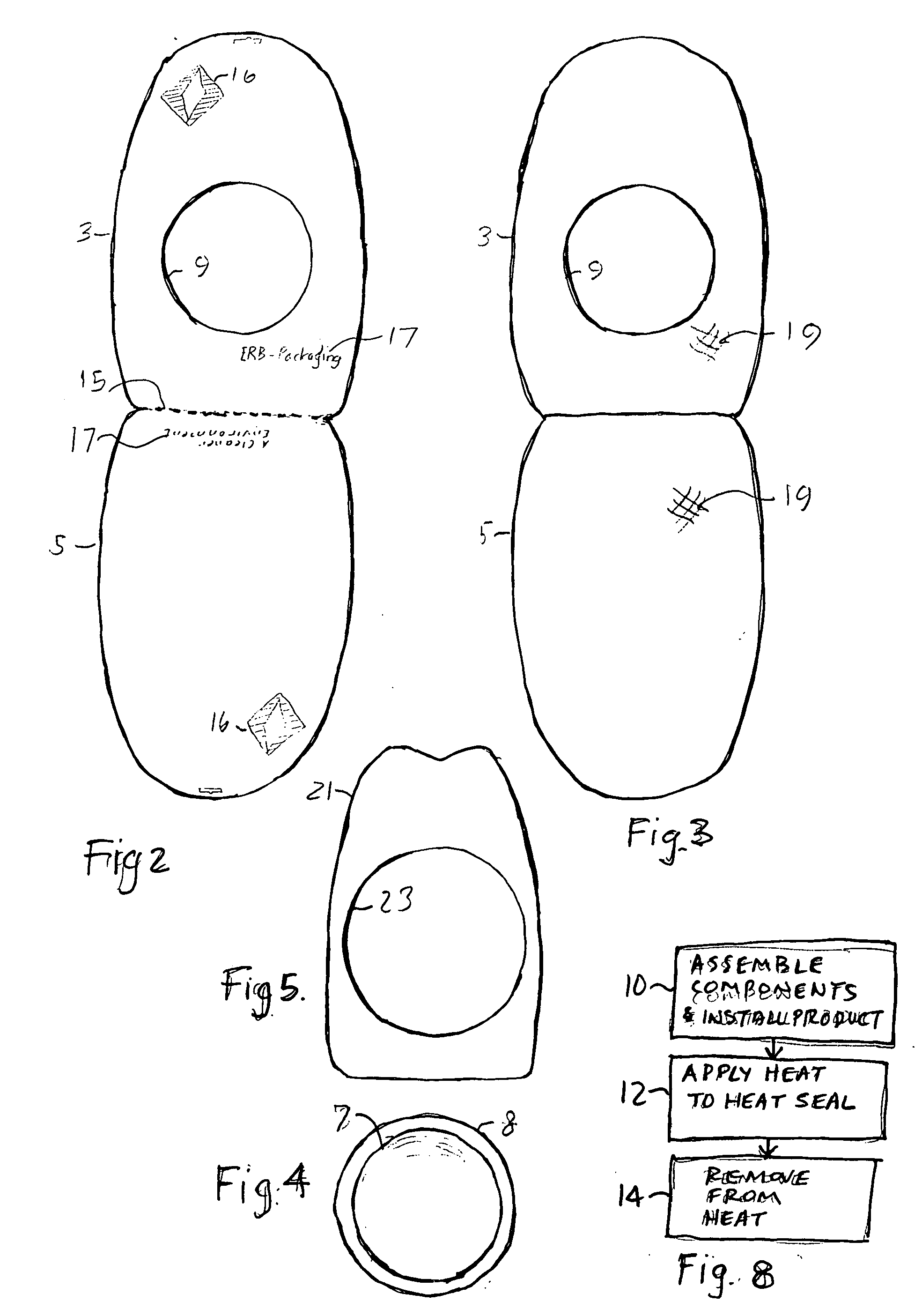

[0050]Reference is made to the embodiment of FIG. 1, illustrating an embodiment of the new blister card or package 1 that is constructed in accordance with the invention. The blister package contains a cover layer 3 that provides an upper or top surface of the base and a base layer 5 that provides a rear or underside surface, not fully visible in the figure, to the blister card. Layers 3 and 5 are formed of an opaque paperboard material. Both layers are relatively flat and smooth in appearance, initially, but following assembly provide a embossed or raised appearance at least on the upper surface, an exception later discussed at length. Text and graphic material, including information about the product in the package, is printed on both the top and underside surfaces of the blister card, but for clarity that printed matter is not fully illustrated in this figure.

[0051]A circular dome 7 of transparent plastic protrudes out of a circular opening 9 in the top surface of layer 3. Dome 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com