Feed Screw For Eccentric Screw Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

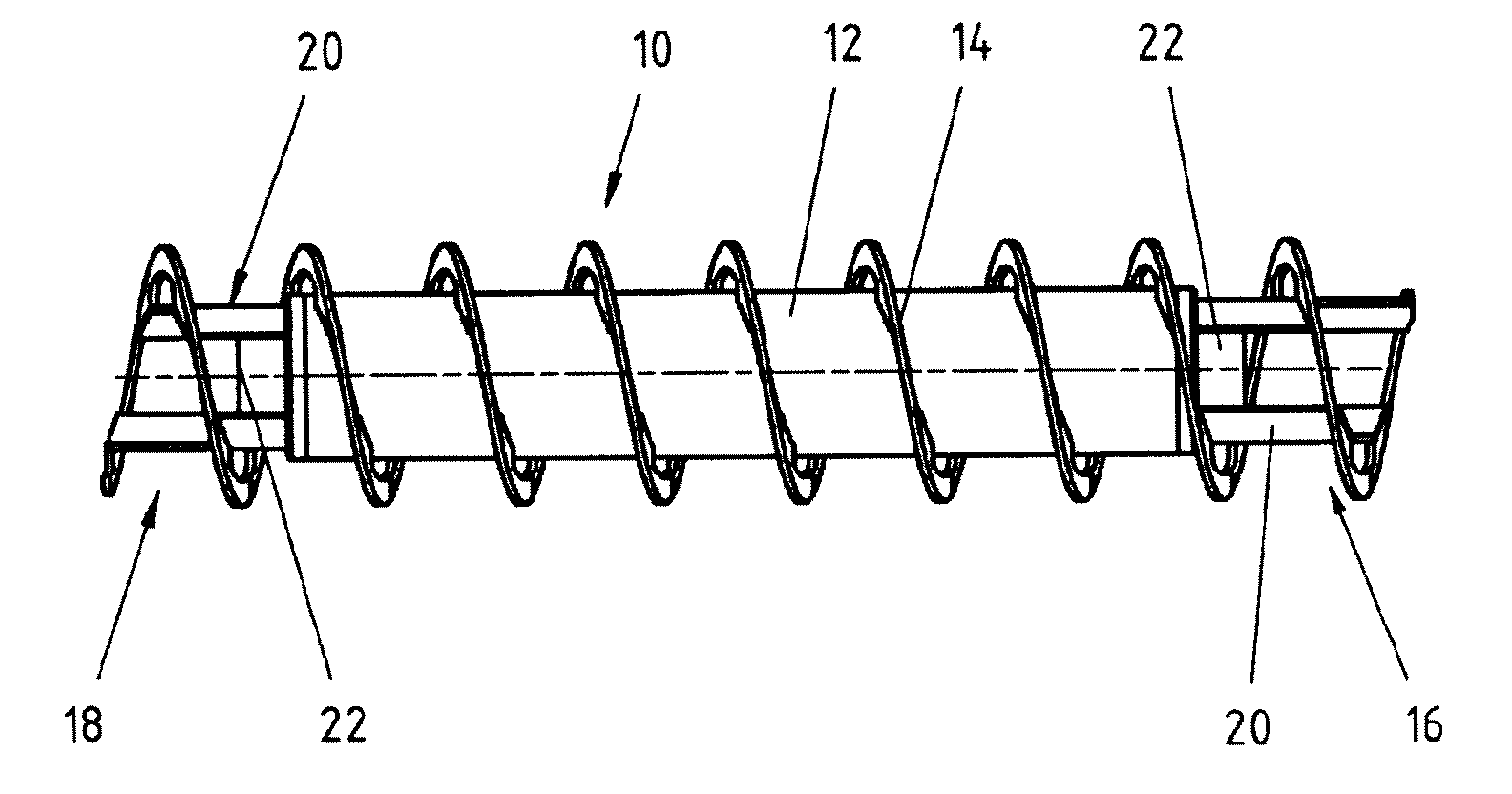

[0030]FIG. 1 shows a design possibility of a feed screw 10 with a screw pipe 12. A screw 14 is welded on to the circumferential surface of the screw pipe 12. On both ends 16, 18 of the screw pipe 12, pipe segments 20 for fastening the screw 14 are provided. Each of the pipe segments 20 ends at the point at which the screw 14 ends in axial direction. In the region of the pipe elements 20, couplings 22 for the joints not shown are provided at both ends. The screw 14 is manufactured from flat band-shaped material.

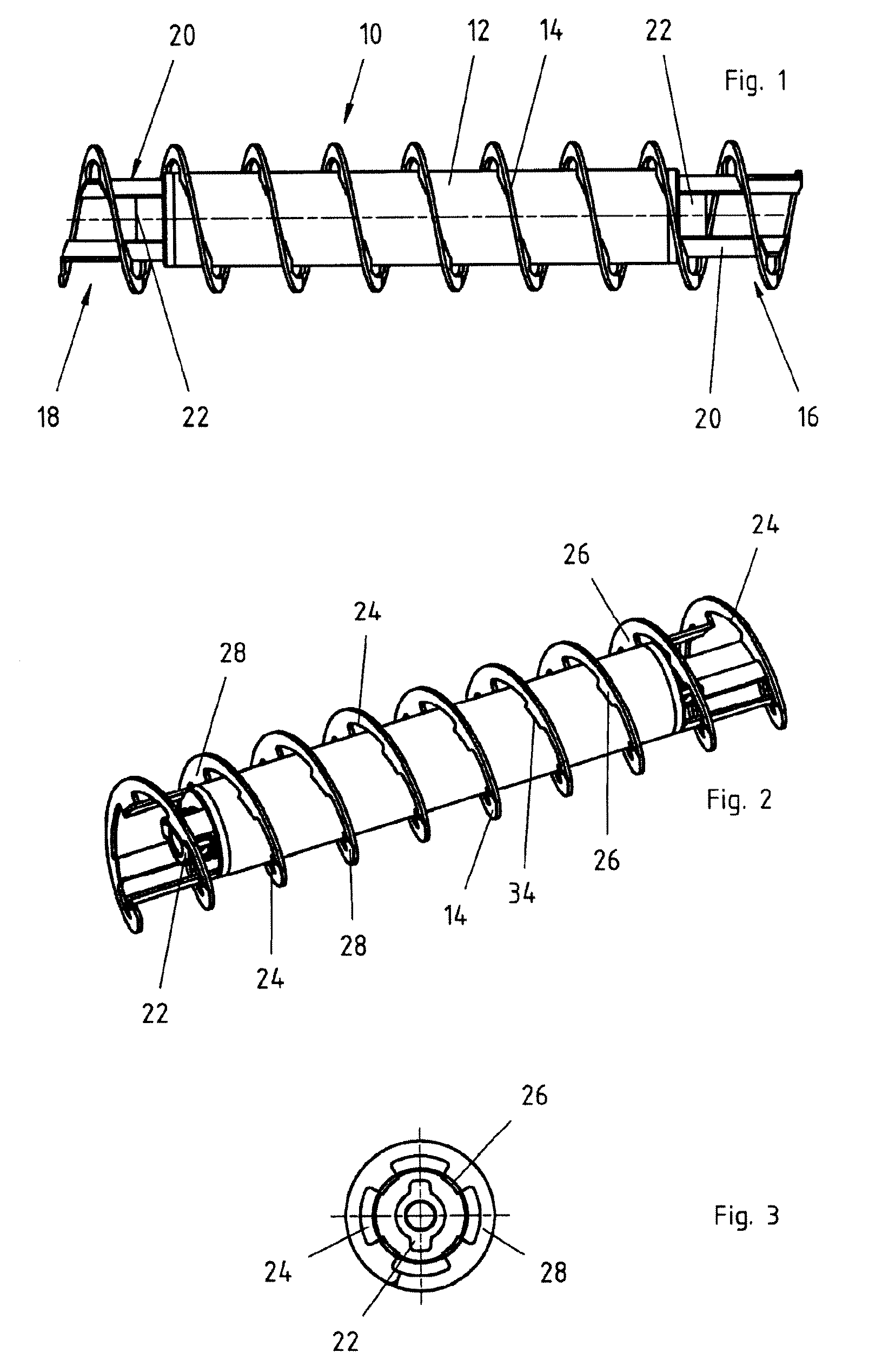

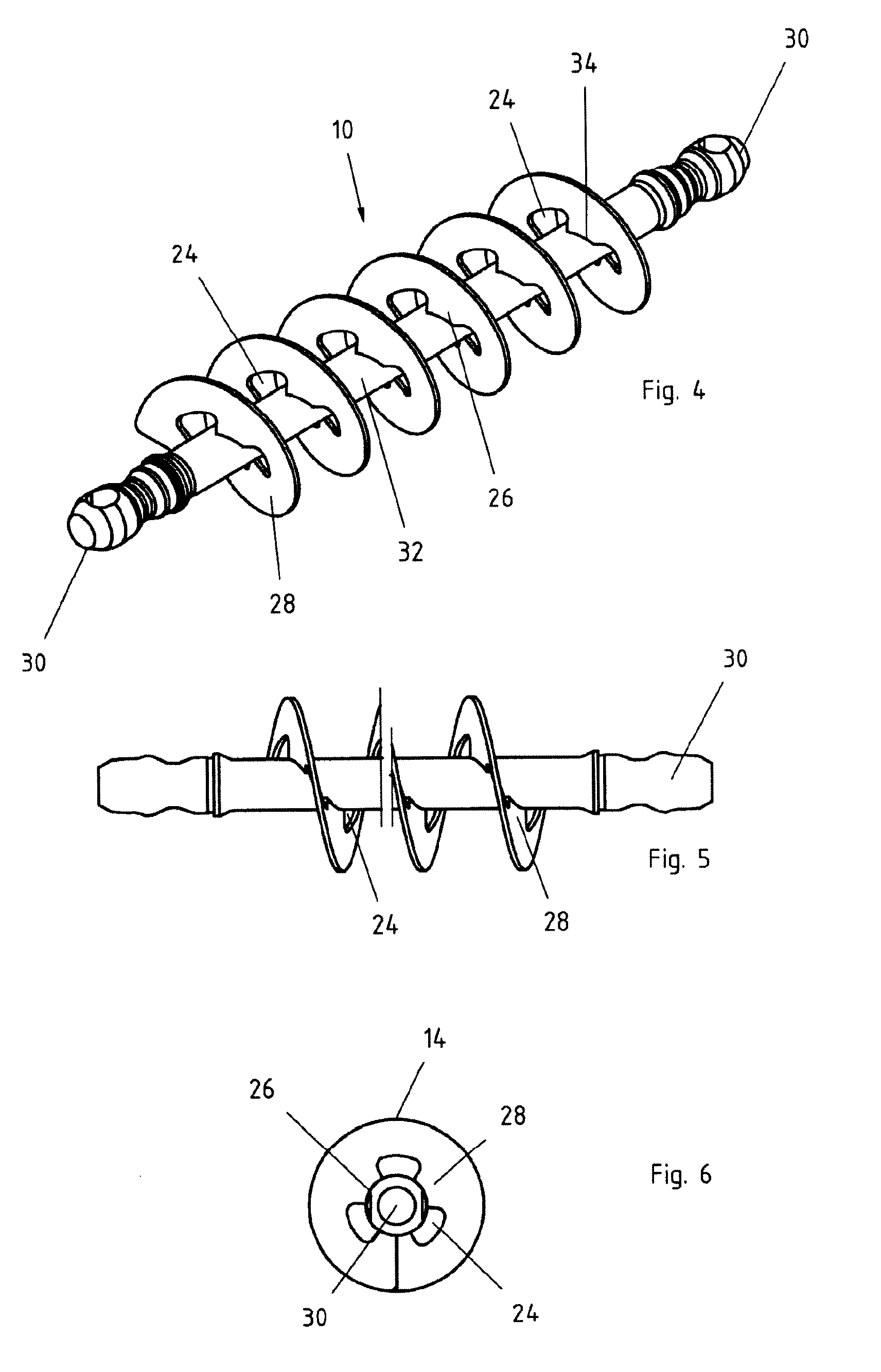

[0031] The design of the screw 14 can be more clearly seen in FIG. 2. From the perspective representation it becomes evident that the screw 14 is provided with perforations 24 and webs 26. Each screw root 34 of the webs 26 is connected with the pipe segment 20 or the coupling shaft 32 for example through a welding operation. While the medium in axial direction flows from the rotor region back to the pump inlet through the perforations of the feed screw closely along the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com