Split tank system for a toilet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

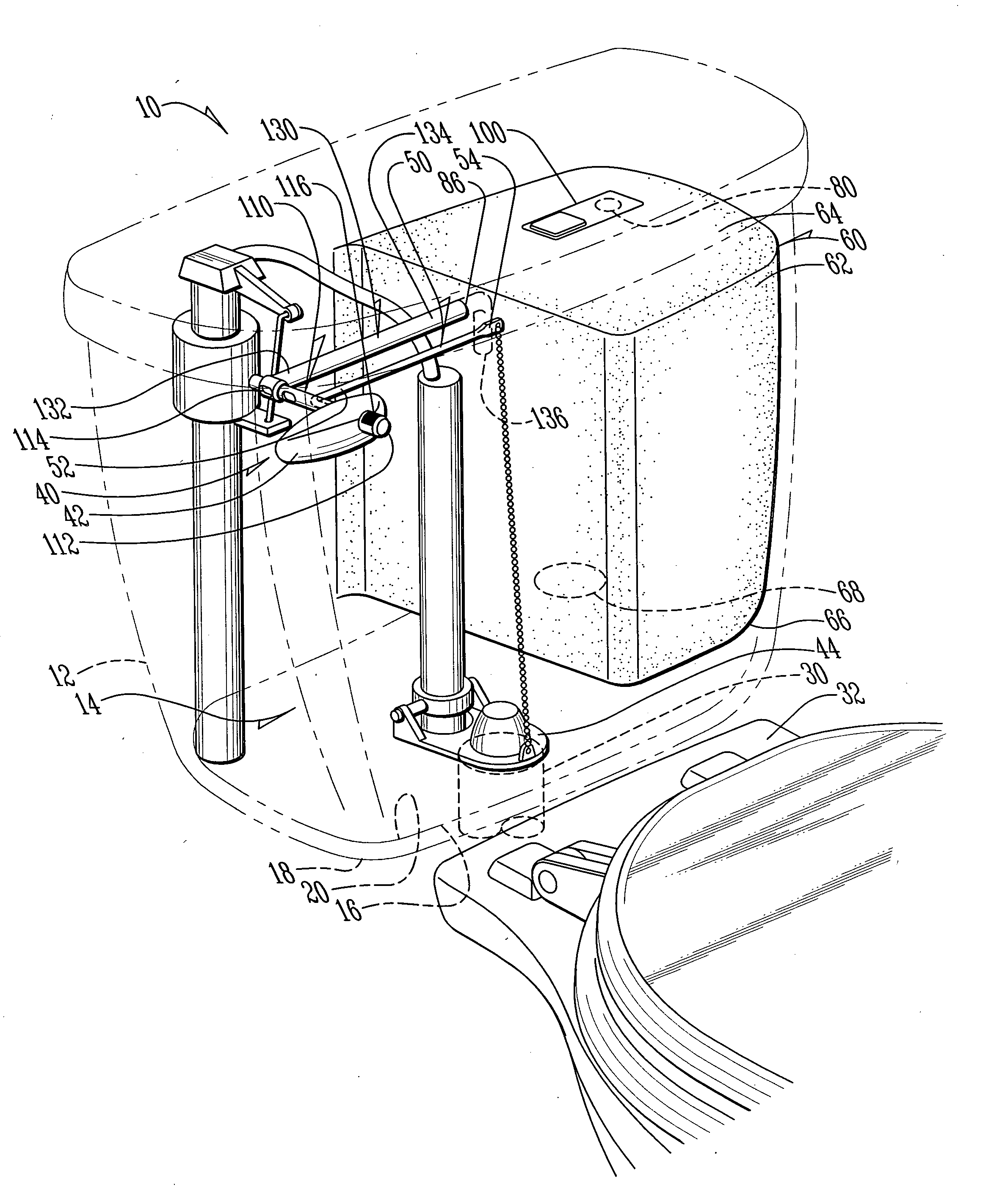

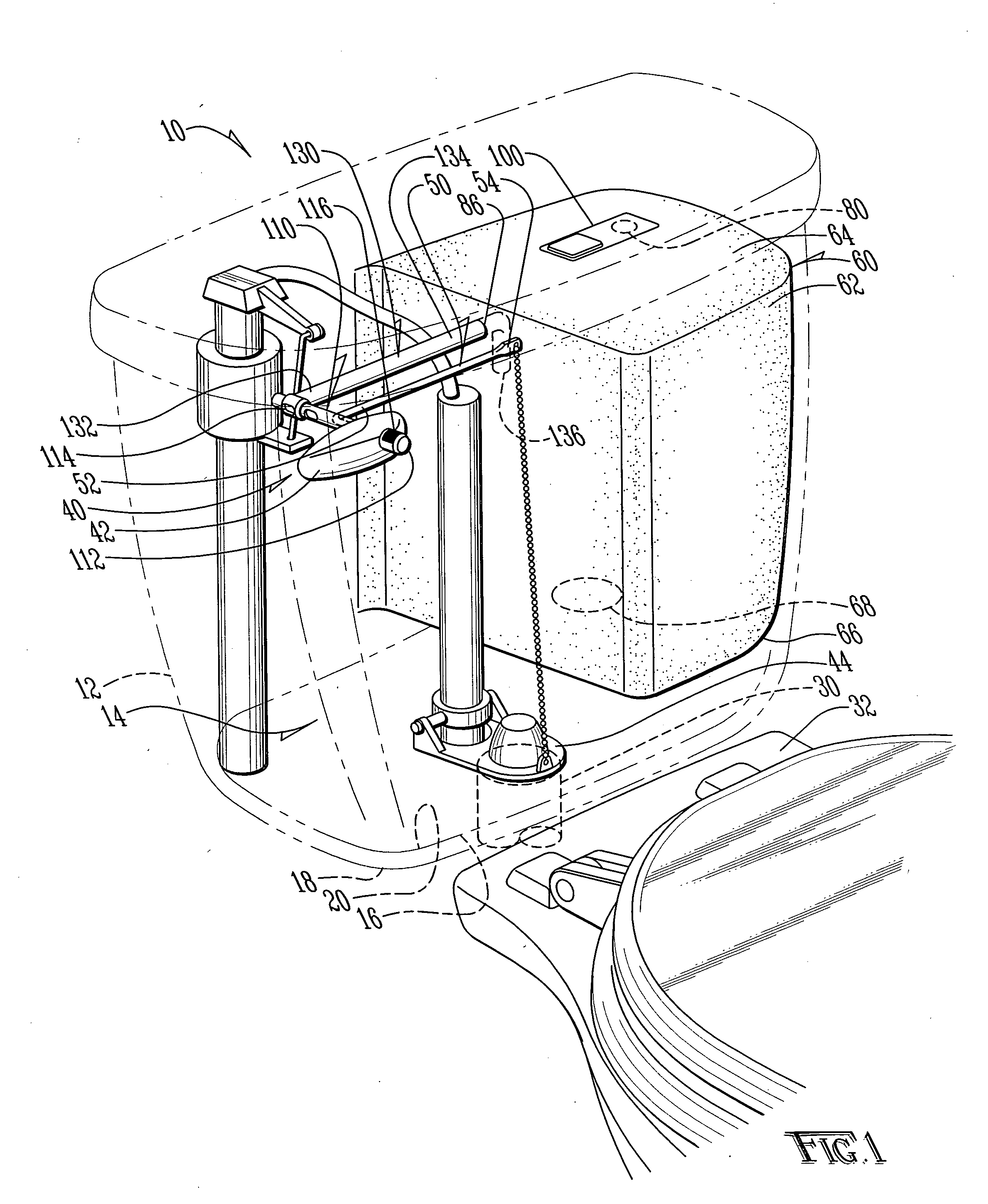

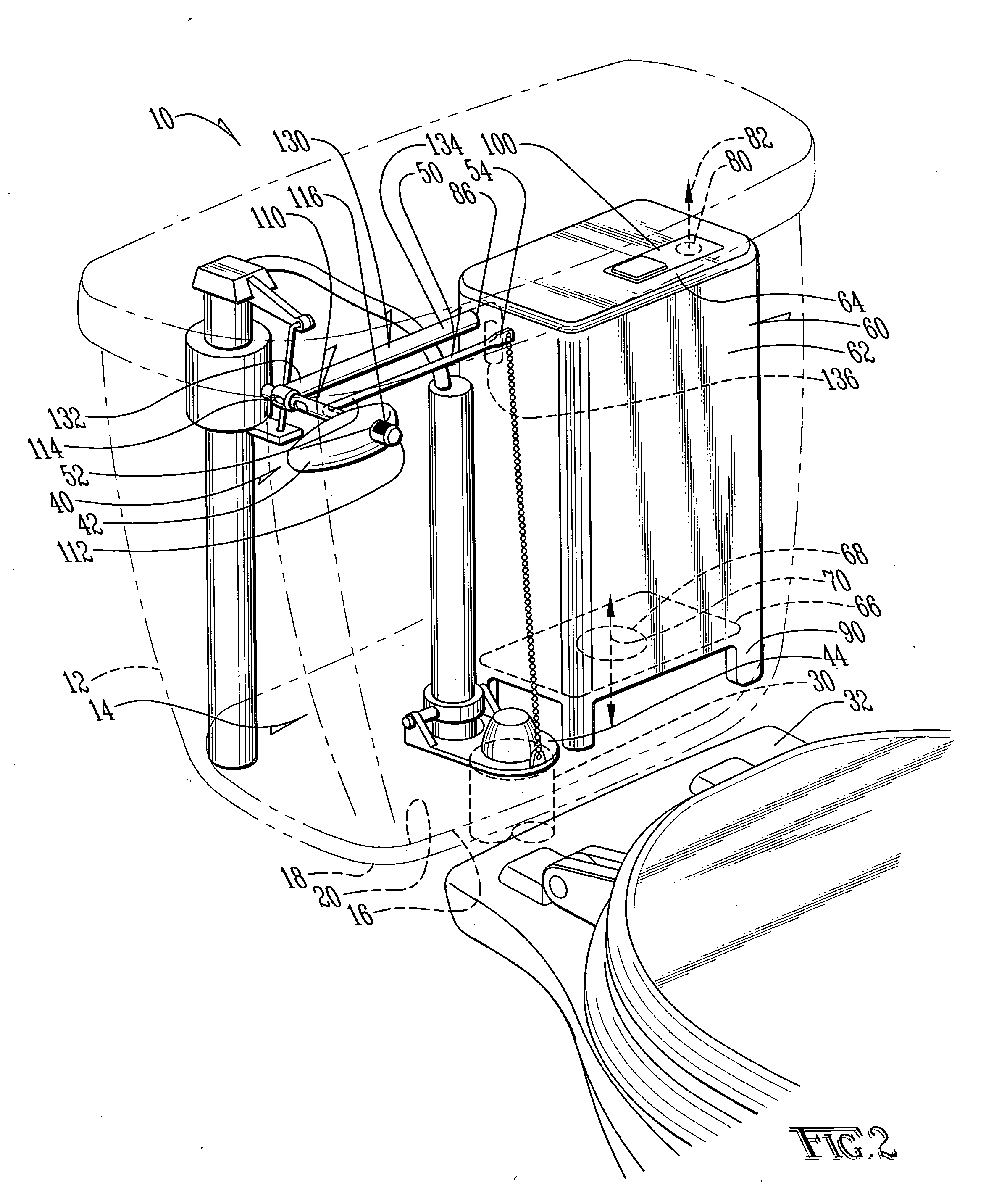

[0015]Referring to the figures, it can be understood that the present invention is embodied in a water-saving toilet 10 which can be easily adjusted to accommodate full or partial flushes. Toilet 10 comprises a water closet flush water storage tank 12 which is associated with a water closet system 14 having the usual toilet bowl and associated plumbing as will be understood by those skilled in the art. Tank 12 is known per se and includes a first wall 16 which is a front wall when the storage tank is in use as indicated in the figure and a second wall 18 which is a bottom wall when the storage tank is in use. Second wall 18 has an inner surface 20.

[0016]A water outlet port 30 is defined through the second wall and is fluidically connected with a bowl 32 which will contain waste products when in use as is the known case. A flush mechanism 40 is used to operate toilet 10 in a known manner and includes a flush operating handle 42 pivotally mounted on the storage tank and which is pivot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap