Heat exchanger and manufacture method for the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

First Embodiment

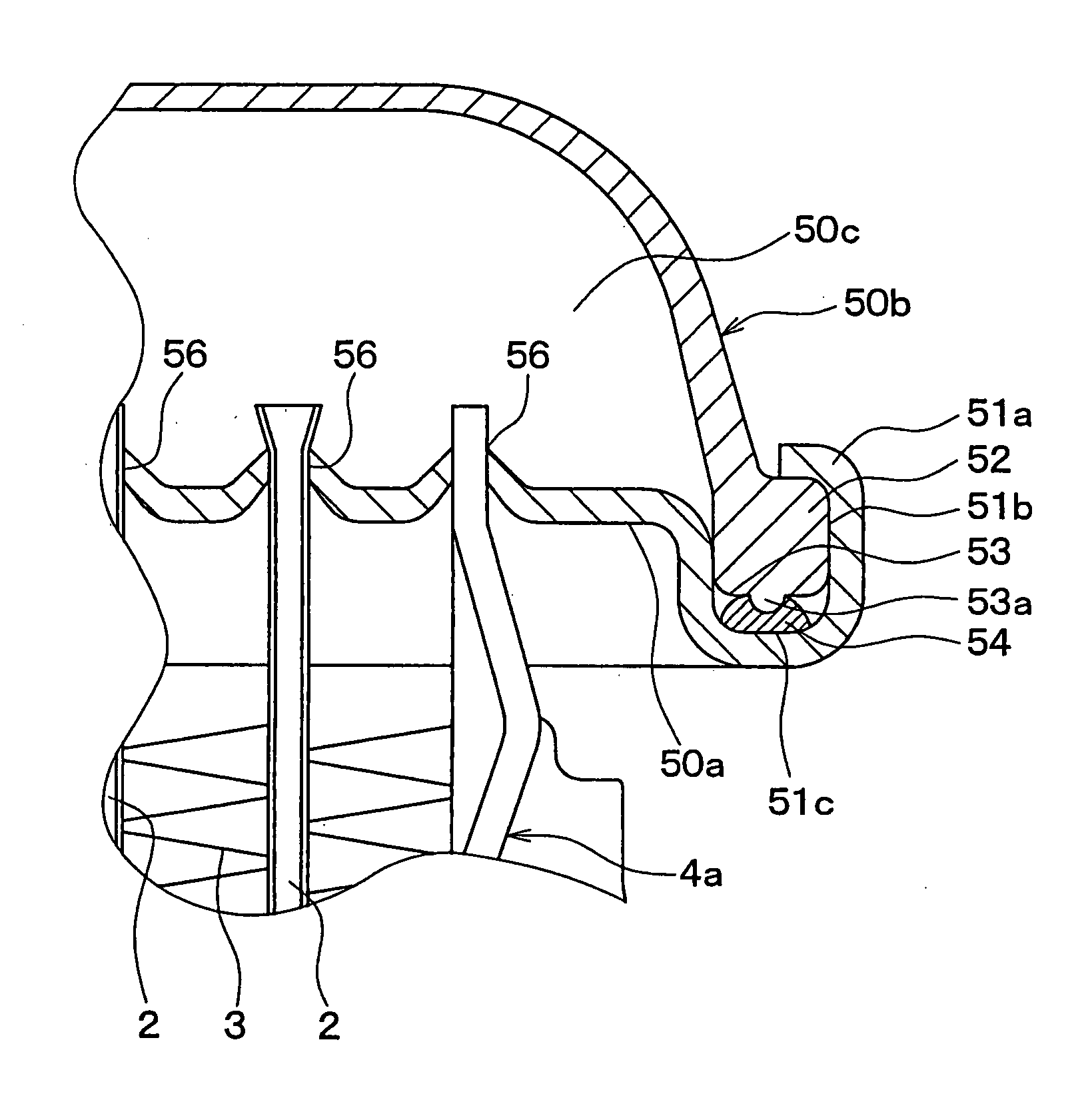

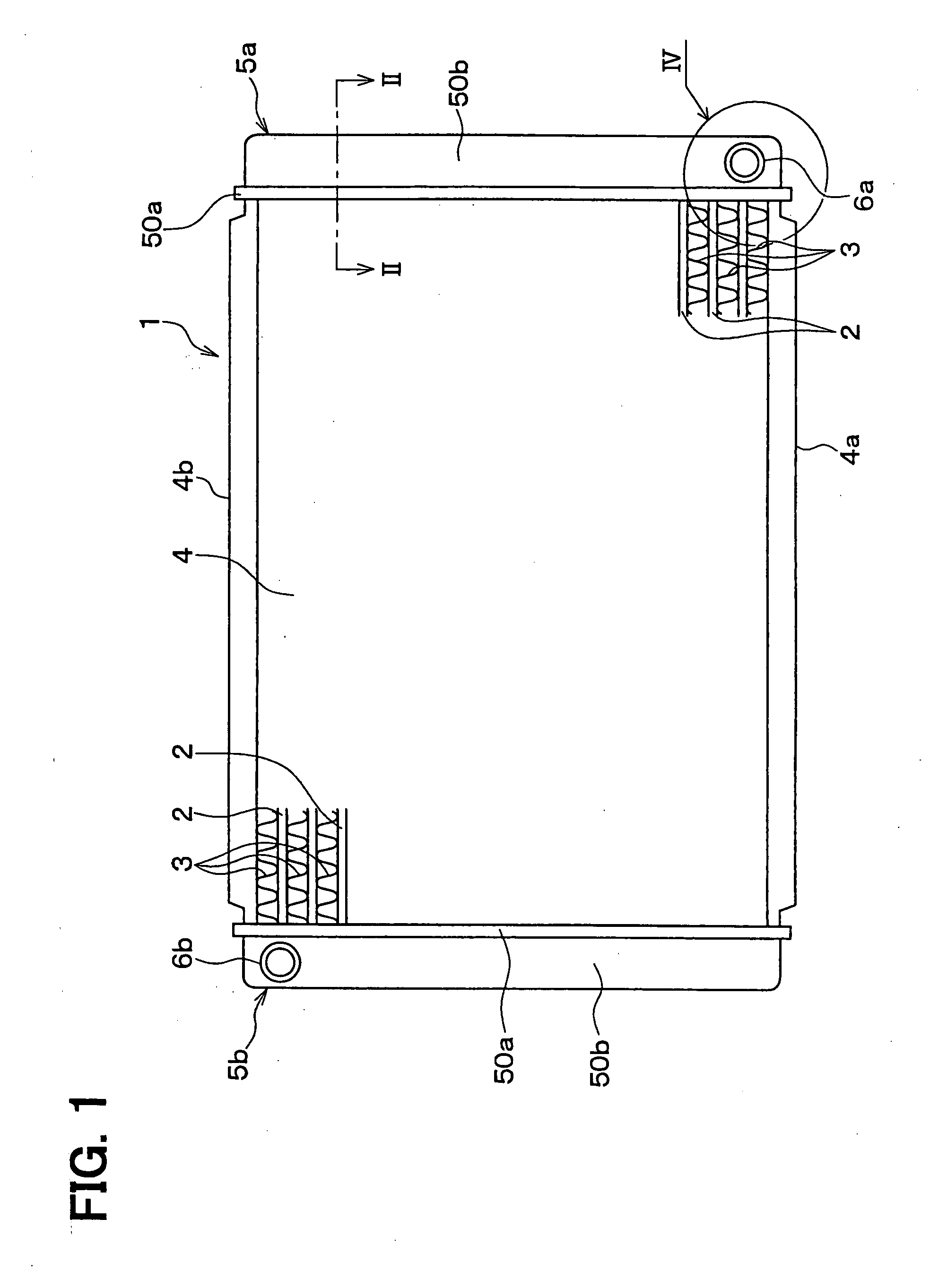

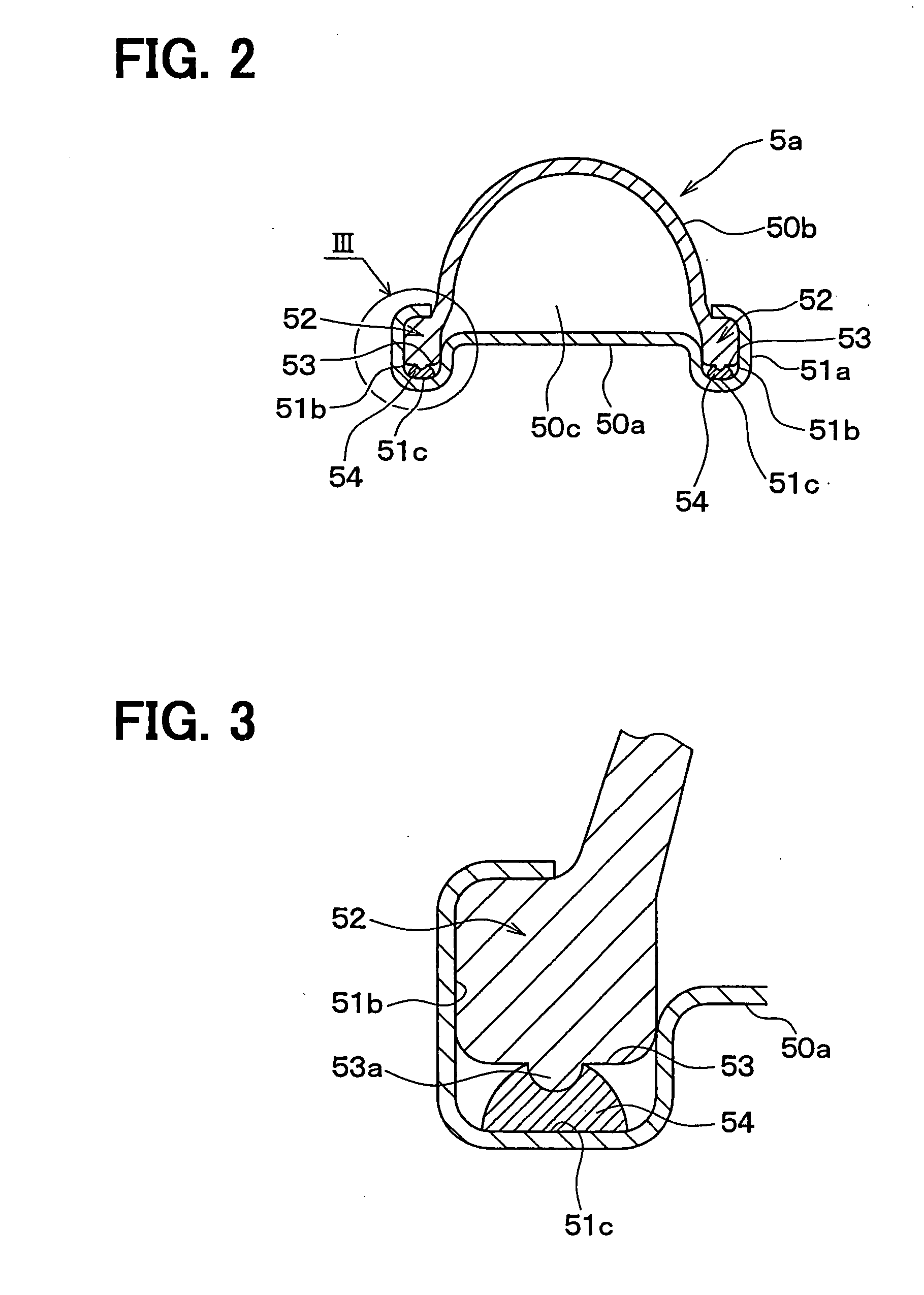

[0034]A heat exchanger according to a first embodiment of the present invention will be described with reference to FIGS. 1-9. The heat exchanger can be suitably used as a radiator 1 of a vehicle, for example. The radiator 1 can be arranged in an engine cabin of the vehicle, to cool fluid (e.g., cooling water) by air blown by a blower.

[0035]As shown in FIG. 1, the radiator 1 is provided with a core unit 4 which includes multiple tubes 2 and multiple fins 3, two side plates 4a, 4b and two header tanks 5a and 5b.

[0036]The tube 2 is constructed of a flat pipe in which cooling water from the engine flows. The tube 2 can be made of a light metal having a high heat conductivity, for example, aluminum. In this embodiment, the tube 2 is constructed of a clad material which surface (facade surface or / and back surface) is covered by a filler material.

[0037]The fin 3 is joined to the outer surface of the tube 2 to increase the area of the heat transferring of the tube 2 with a...

second embodiment

[0078]In the above-described first embodiment, the one tank inner space is formed in the header tank 5a. According to a second embodiment of the present invention, the multiple tank inner spaces (for example, two tank inner spaces) are formed in the header tank 5a.

[0079]As shown in FIG. 10, for example, a partition wall 6c is arranged in the tank body 50b to partition the space in the tank body 50b into the two tank inner spaces 60a and 60b. With reference to FIG. 11, the seal surface 51c having the ring shape and a seal surface 51d corresponding to the partition wall 6c are arranged at the core plate 50a. That is, each of the inner spaces in the header tank 5a is surrounded by the seal member 54.

[0080]In this case, the seal material is applied along the seal surface 51c and the seal surface 51d to respectively surround the inner space 60a and the inner space 60b. As shown in FIG. 12 which is a cross section taken along the line XII-XII in FIG. 11, the bottom of the groove portion ...

third embodiment

[0085]A third embodiment according to the present invention will be described with reference to FIG. 13. According to this embodiment, a recess 51e is formed at the bottom of the groove portion 51b (having U-like shaped cross section) of the core plate 50a of the header tank 5b, and is positioned within the seal surface 51c of the core plate 50a.

[0086]The recess 51e extends around the periphery of the core plate 50a along the seal surface 51c, to have a ring shape. In this case, the gel seal material or the liquid seal material is applied to fill the recess 51e, and hardened.

[0087]Thus, the seal material is hardened in such a manner that the seal material is engaged in the recess 51e, so that it is difficult for the seal member 54 to leaving the seal surface 51c. Therefore, when the core plate 50a and the tank body 50b are fastened to each other, the position deviation can be further reduced as compared with the first and the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Tackiness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com