Pipe guides and methods of guiding pipes in snubbing units

a technology of pipe guides and snubbing units, which is applied in the direction of fluid removal, drilling accessories, borehole/well accessories, etc., can solve the problems of reducing affecting the efficiency of snubbing operations, and losing approximately one-half of the effective stroke of snubbing units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

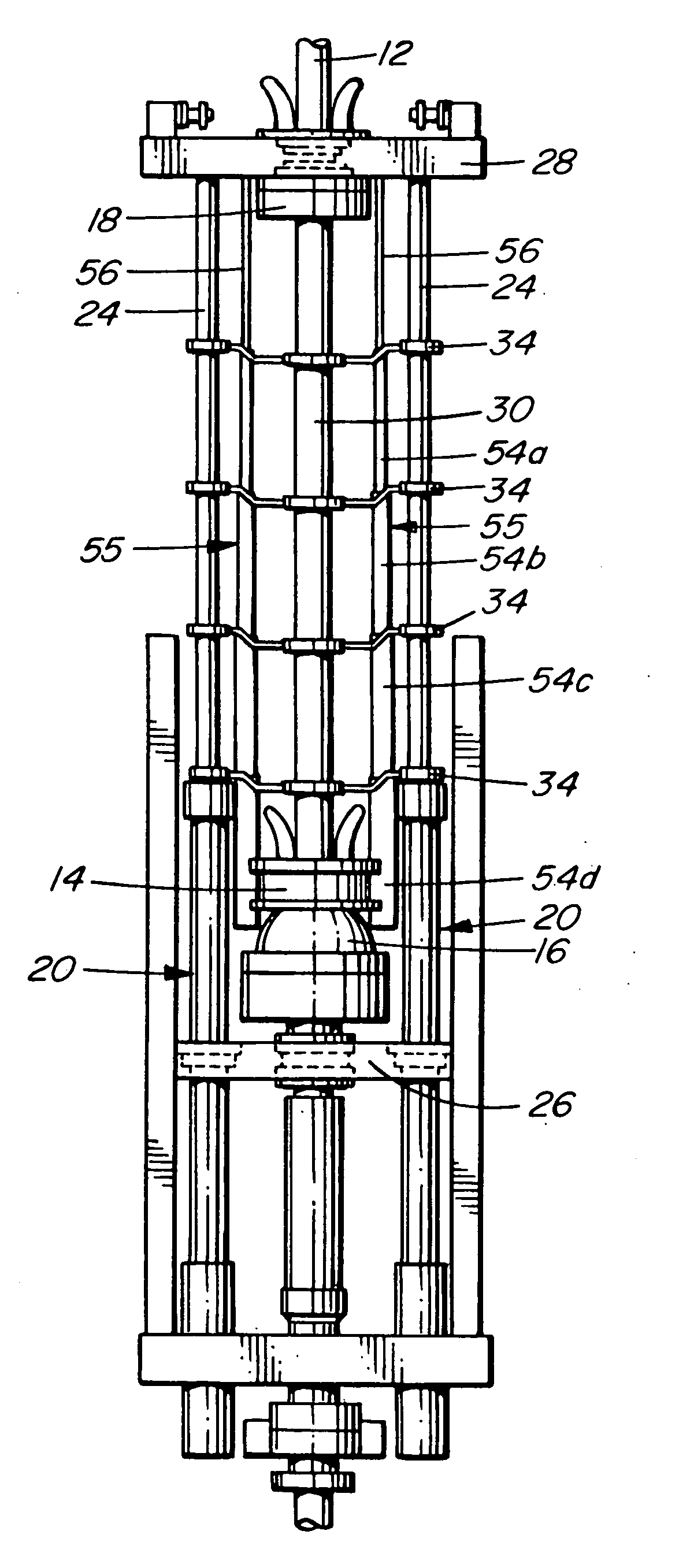

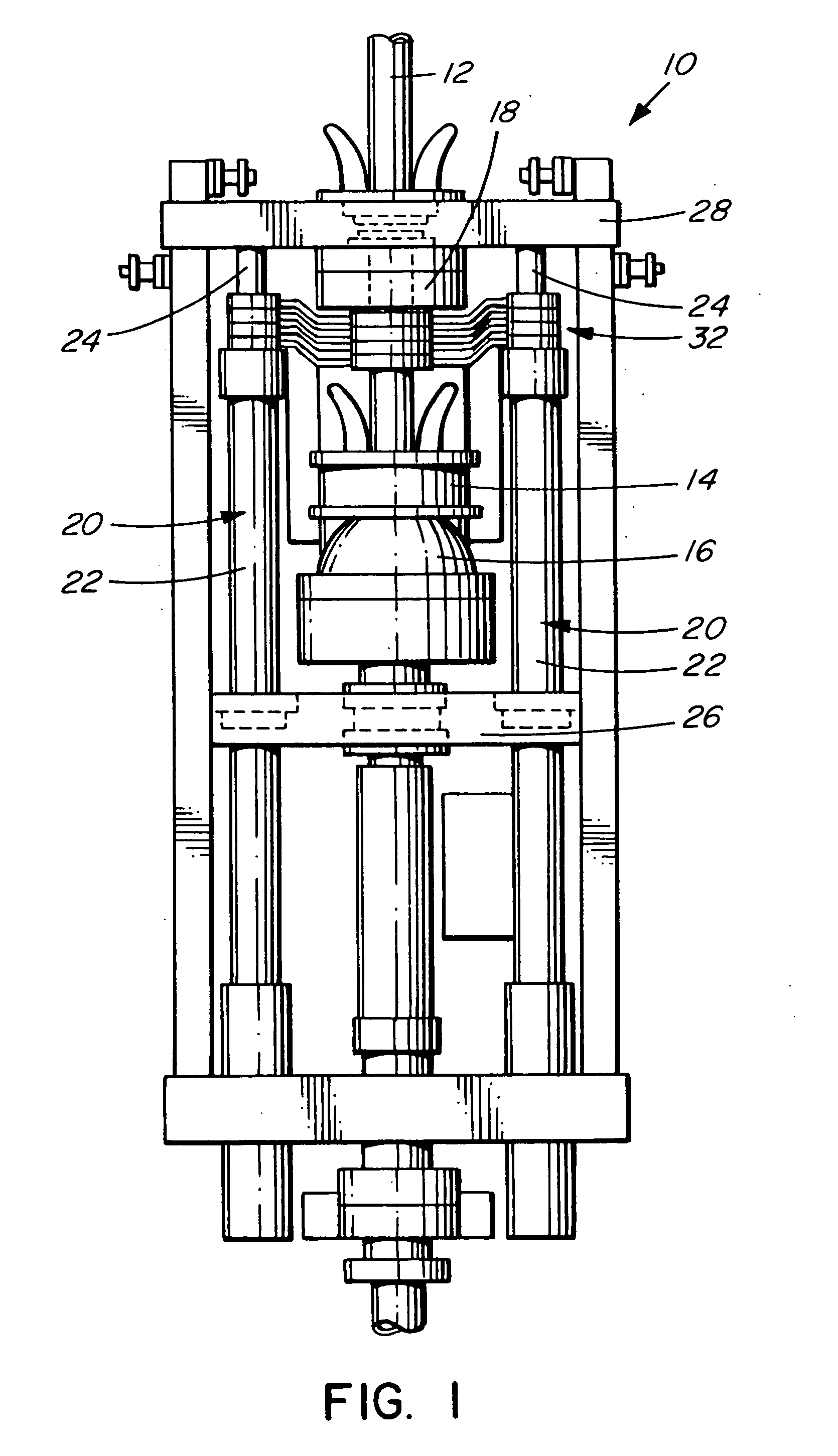

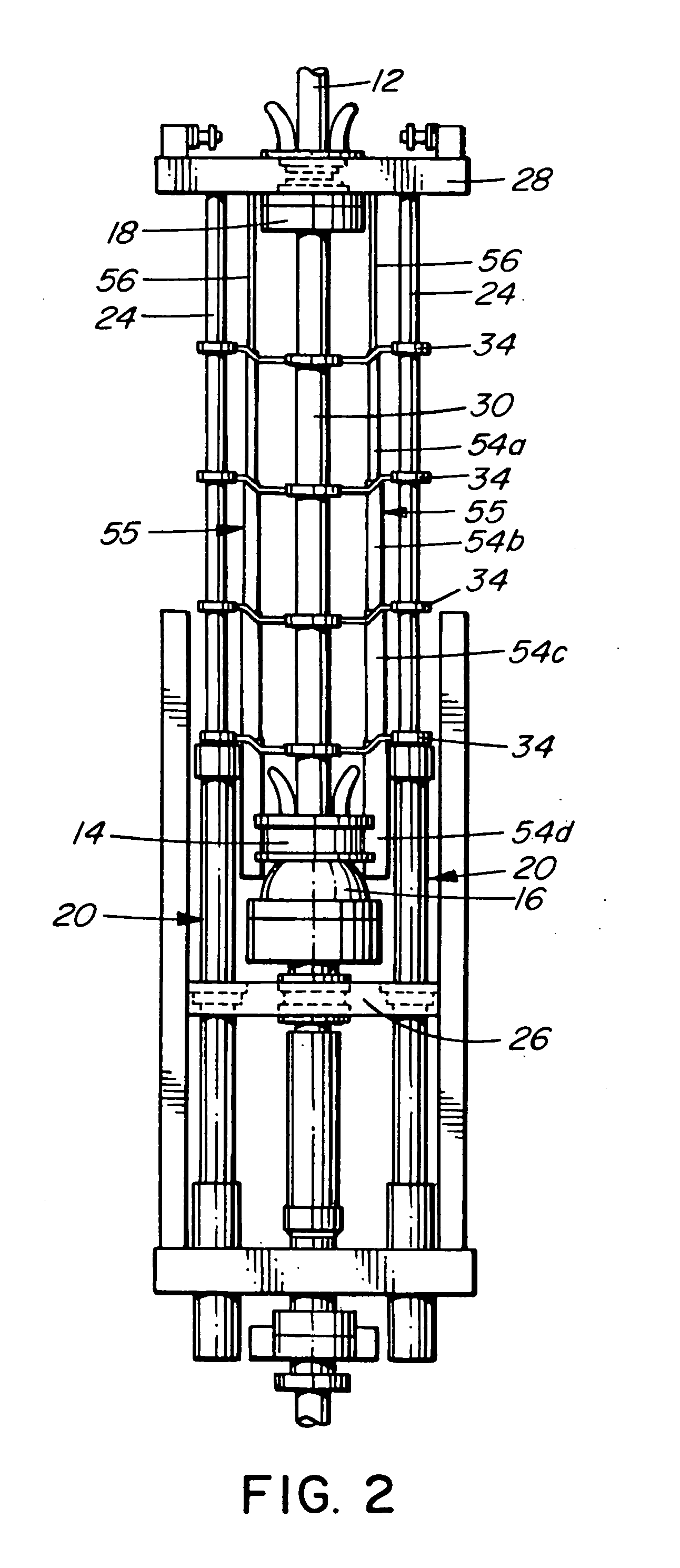

[0028]Referring firstly to FIGS. 1 and 2 of the accompanying drawings, there is shown a pipe snubbing unit, indicated generally by reference numeral 10, for snubbing a vertical pipe 12 into or from an underground well (not shown).

[0029]The snubbing unit 10 has stationary snubbing slips or pipe grippers 14, provided with an underlying blow-out preventor 16, travelling snubbing slips or pipe grippers 18 and a pair of hydraulic jacks 20 for moving the travelling snubbing slips 18 vertically towards and away from the stationary snubbing slips 14.

[0030]The jacks 20 each comprise an hydraulic cylinder 22 from which extends an jack rod 24, the lowermost end of the hydraulic cylinder 22 being mounted on a middle plate 26, and the uppermost end of the jack rod 24 being connected to a travelling plate 28 on which the travelling snubbing slips 18 are mounted.

[0031]In operation of the snubbing unit 10, the jack rods 24 move the travelling snubbing slips 18 vertically up and down relative to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com