Condenser and radiator of air conditioning refrigeration system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

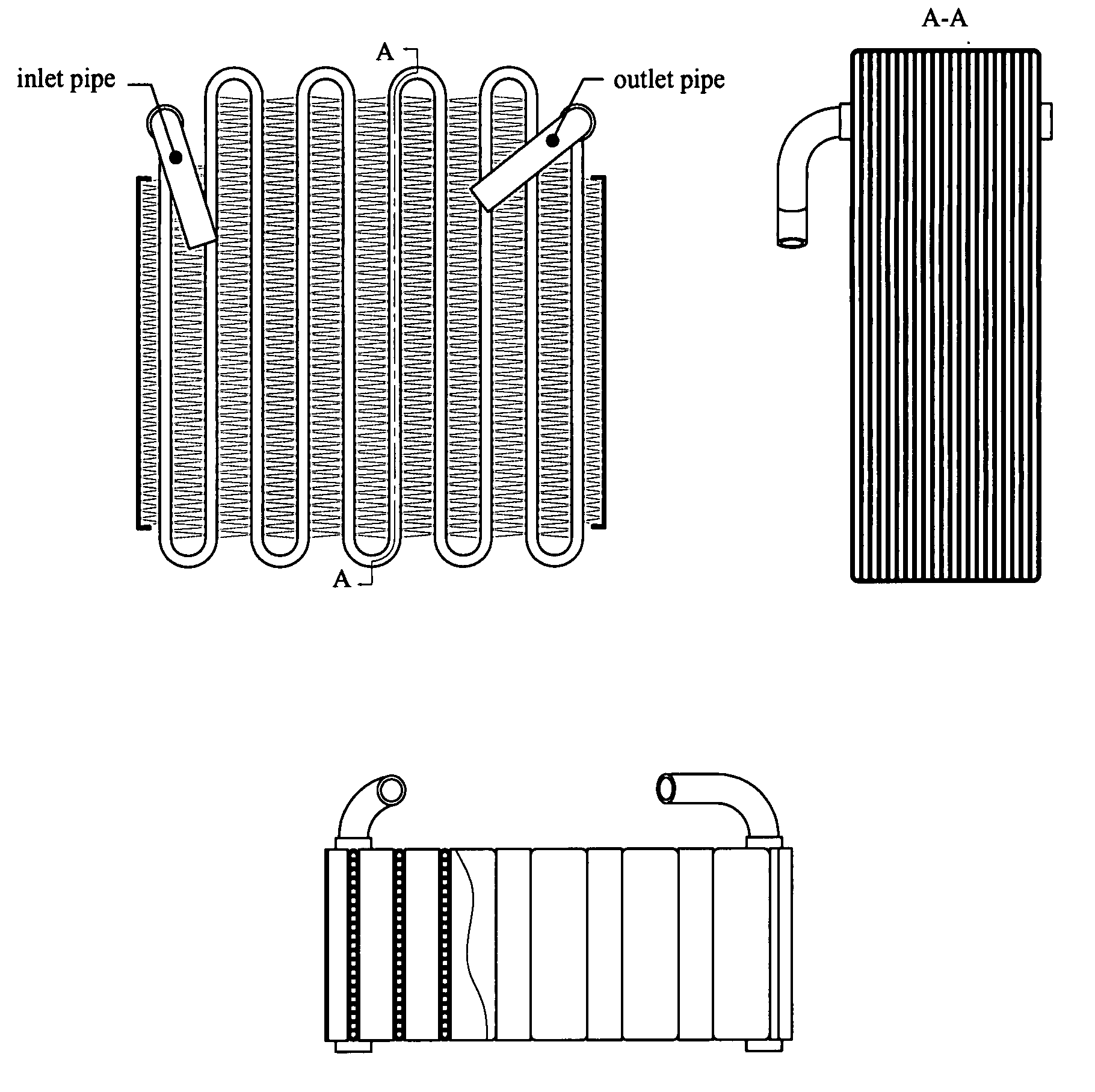

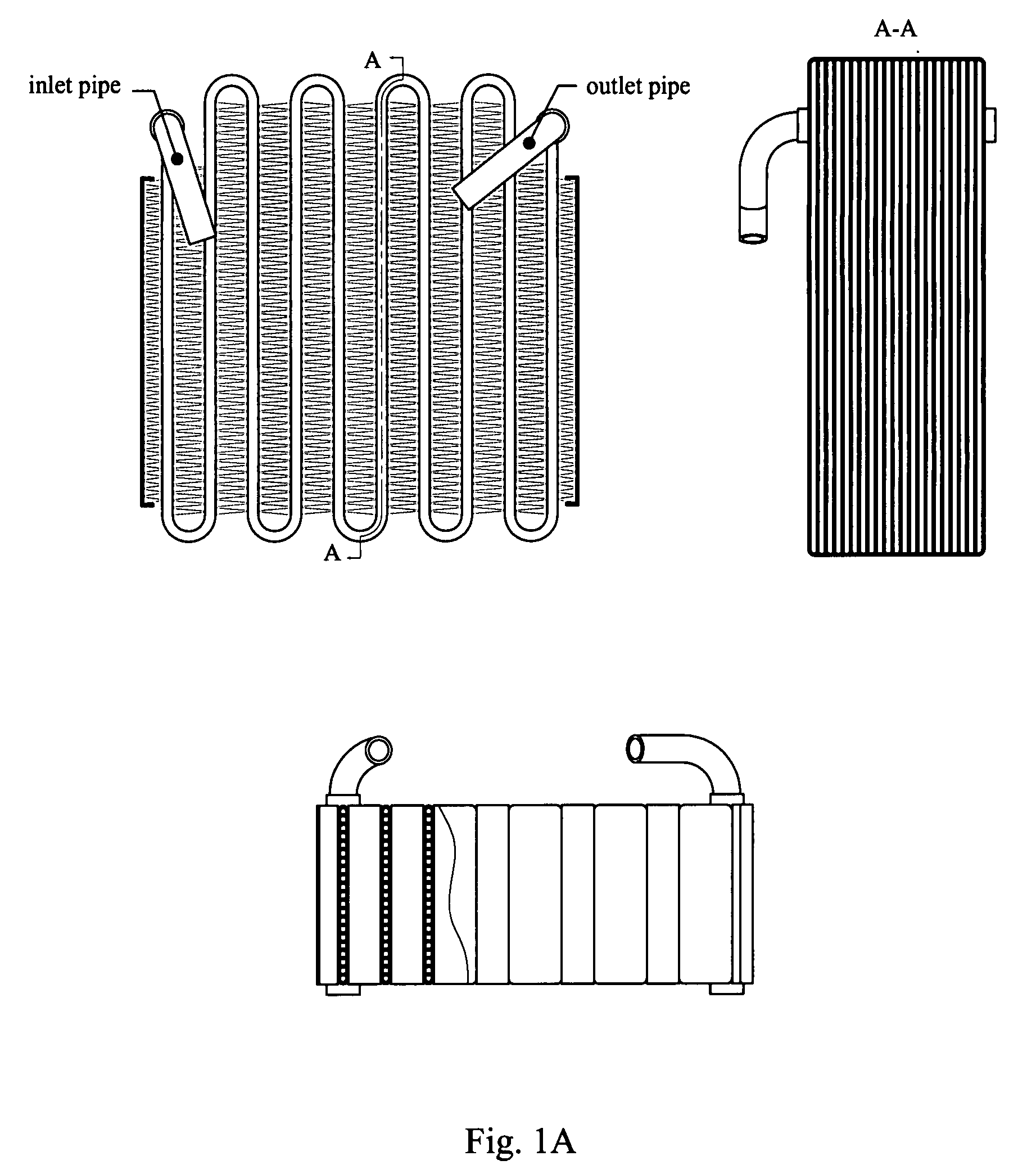

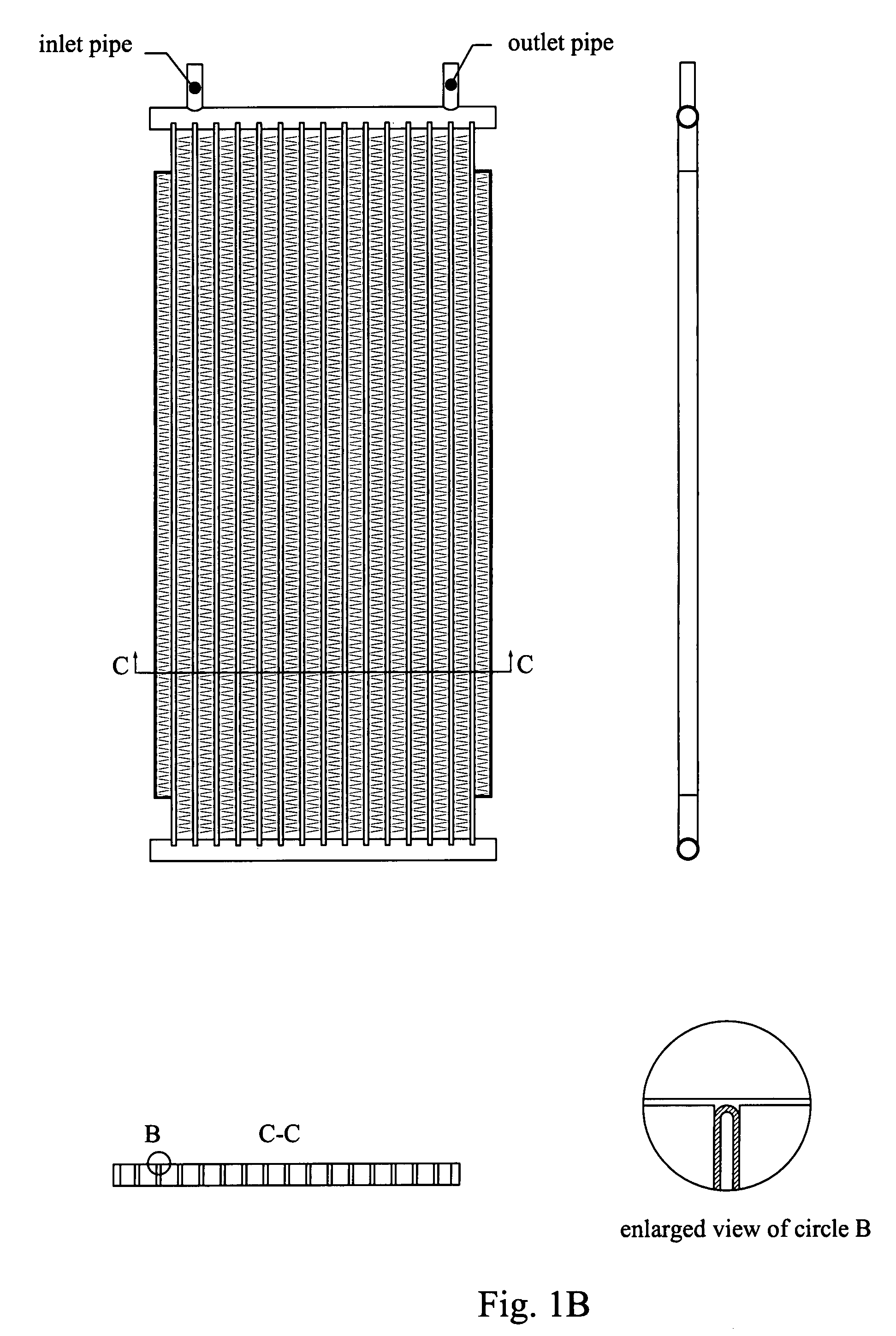

[0042]With reference to the accompanied figures, the embodiments of the present invention will be described in detail as follows. The present invention relates to a condenser and a radiator used in air conditioning refrigeration system. As the structure of the condenser is similar to that of the radiator, the structure of the radiator will be described as an example in the following.

[0043]FIGS. 3-5 show one embodiment of the radiator of the present invention. The radiator 1 comprises a number of radiator units 2, an upper one-way channel 3, a lower one-way channel 4, an inlet port 5 and an outlet port 6. The upper one-way channel 3 is mounted on the upper end of the radiator units 2, and the lower one-way 4 on the lower end thereof. The inlet port 5 and the outlet port 6 are disposed on the two outmost radiator units 2, respectively.

[0044]As shown in FIG. 3, the number of the radiator units is six. However, a single radiator unit together with an inlet port and an outlet port could ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com