Self-regulating turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

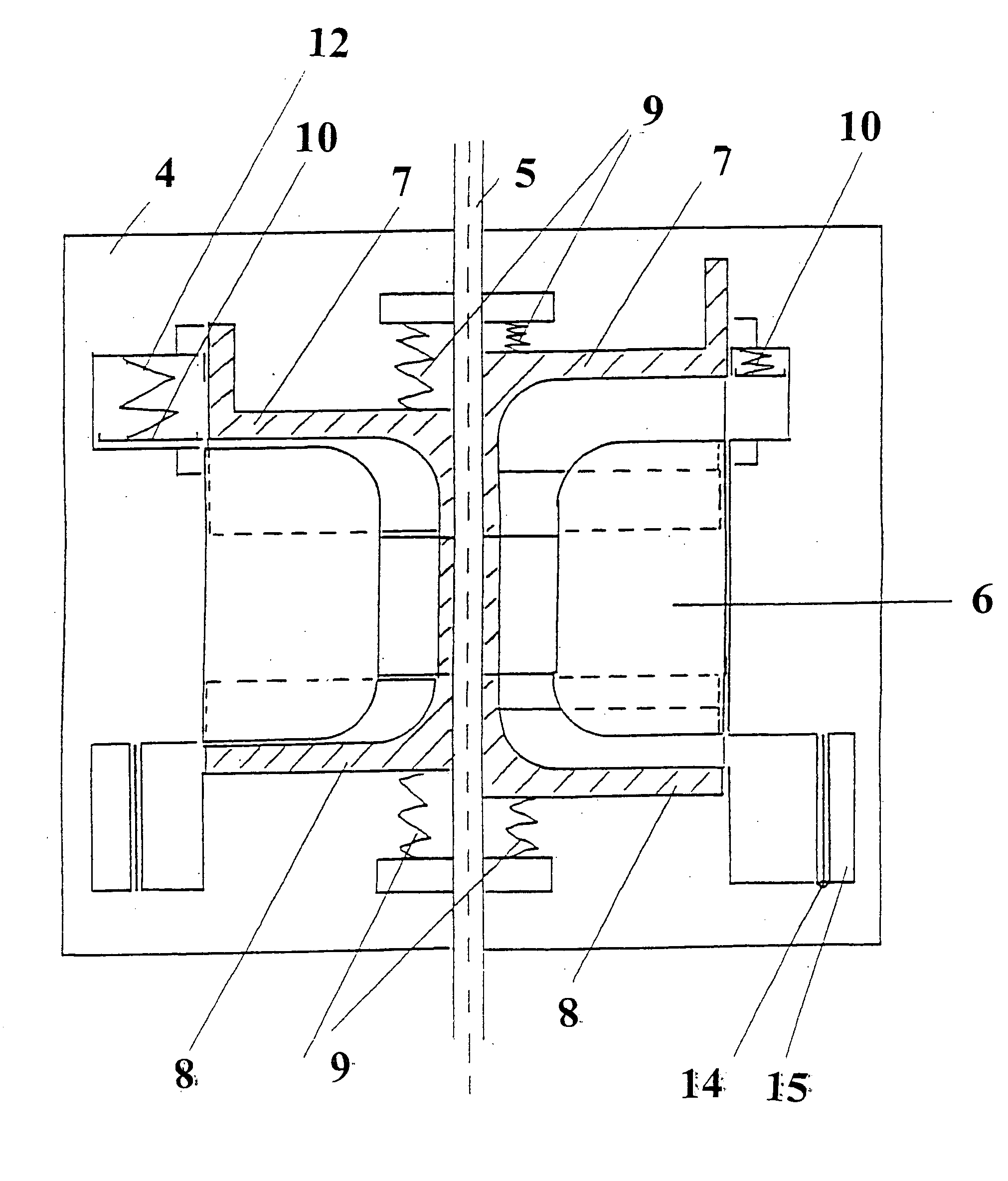

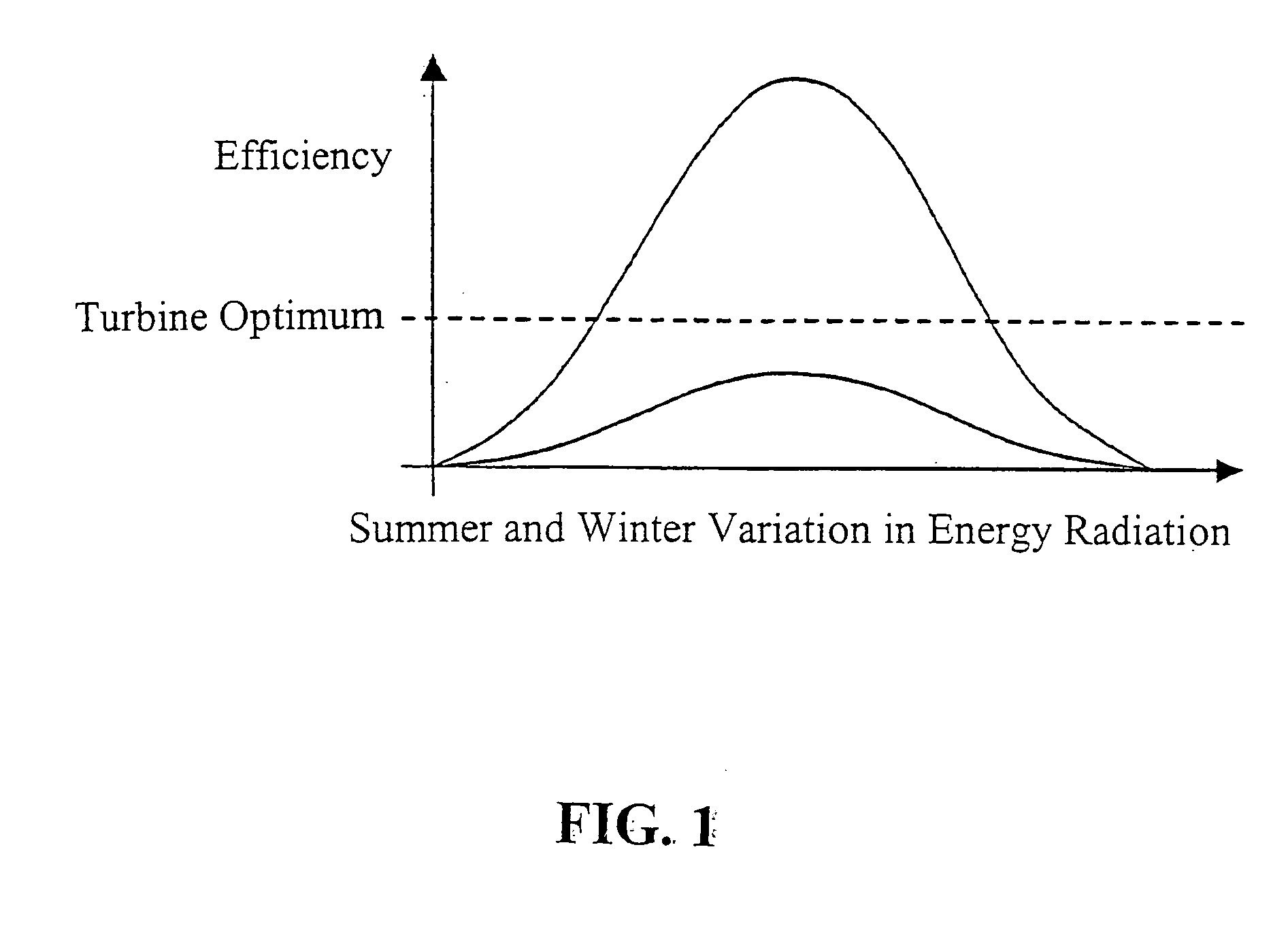

[0053] In one aspect, a turbine is provided with an axial inlet flow and radial outlet flow according to an embodiment of the invention. The turbine is designed for operation with varying gas or steam quantities at varying temperatures or pressures. The flow gap is closed after reaching the rated speed in dependence on the available heated gas or steam quantity or the size of the flow gap between the turbine vanes and / or the turbine blade inclination and / or the length of the turbine vanes is automatically adjusted as a function of pressure and / or temperature and the change in current flow in the generator connected downstream from the turbine is used as an additional regulating quantity for limiting the speed of the turbine.

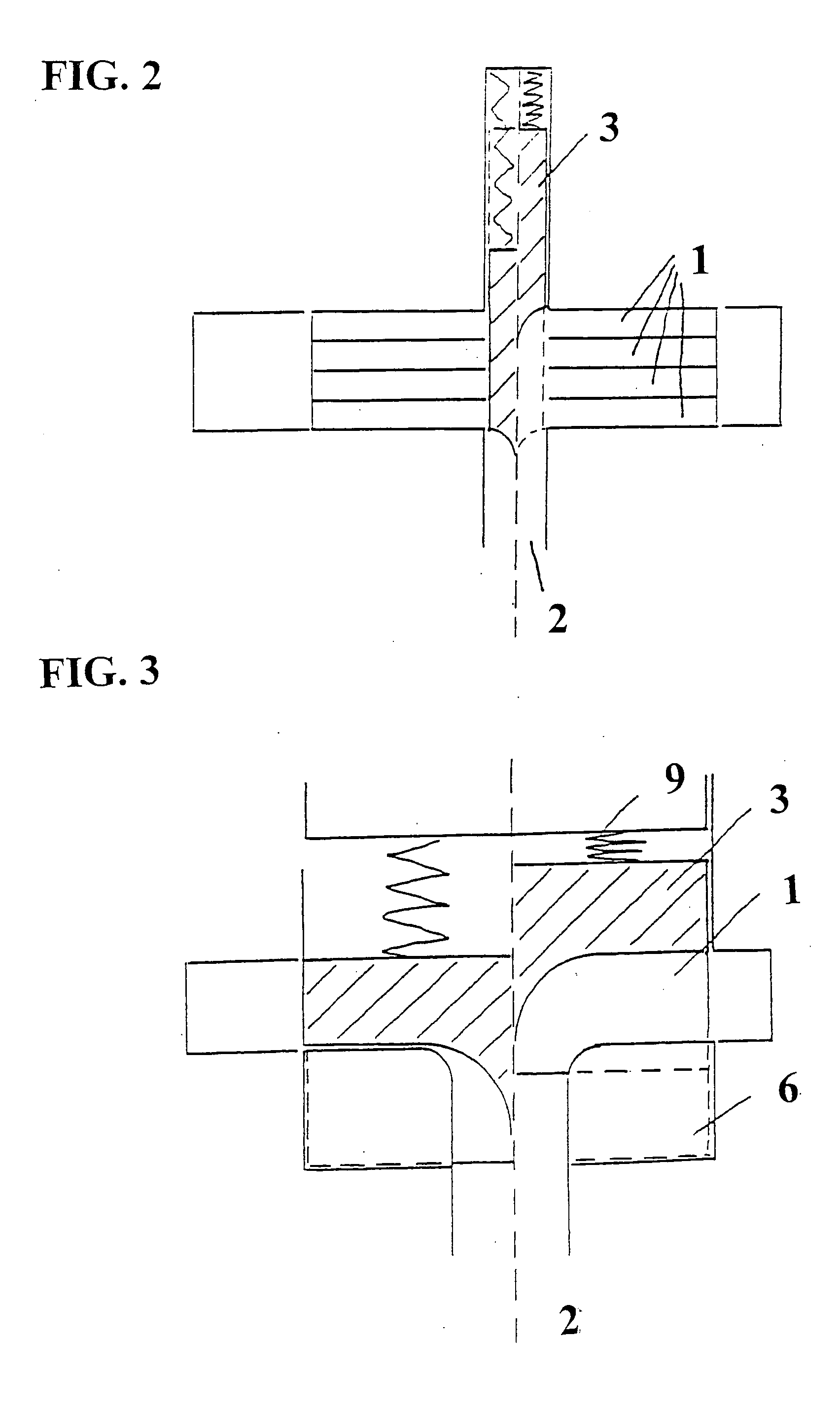

[0054] Referring now in detail to the drawings, FIGS. 2 and 3 show a turbine in which several turbine sets 1 with an axial gas or steam borehole 2 are arranged axially to each other. Each turbine set 1 is arranged on a separating seating disk. In the central gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com