Methods and apparatus for spray forming, atomization and heat transfer

a technology of atomization and heat transfer, which is applied in the direction of molten spray coating, plasma technique, coating, etc., can solve the problems of yield loss of 25-40%, high loss, and yield loss of 10-15%, so as to reduce the need for screening and handling, eliminate the blending step, and minimize the contamination of the furnace lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

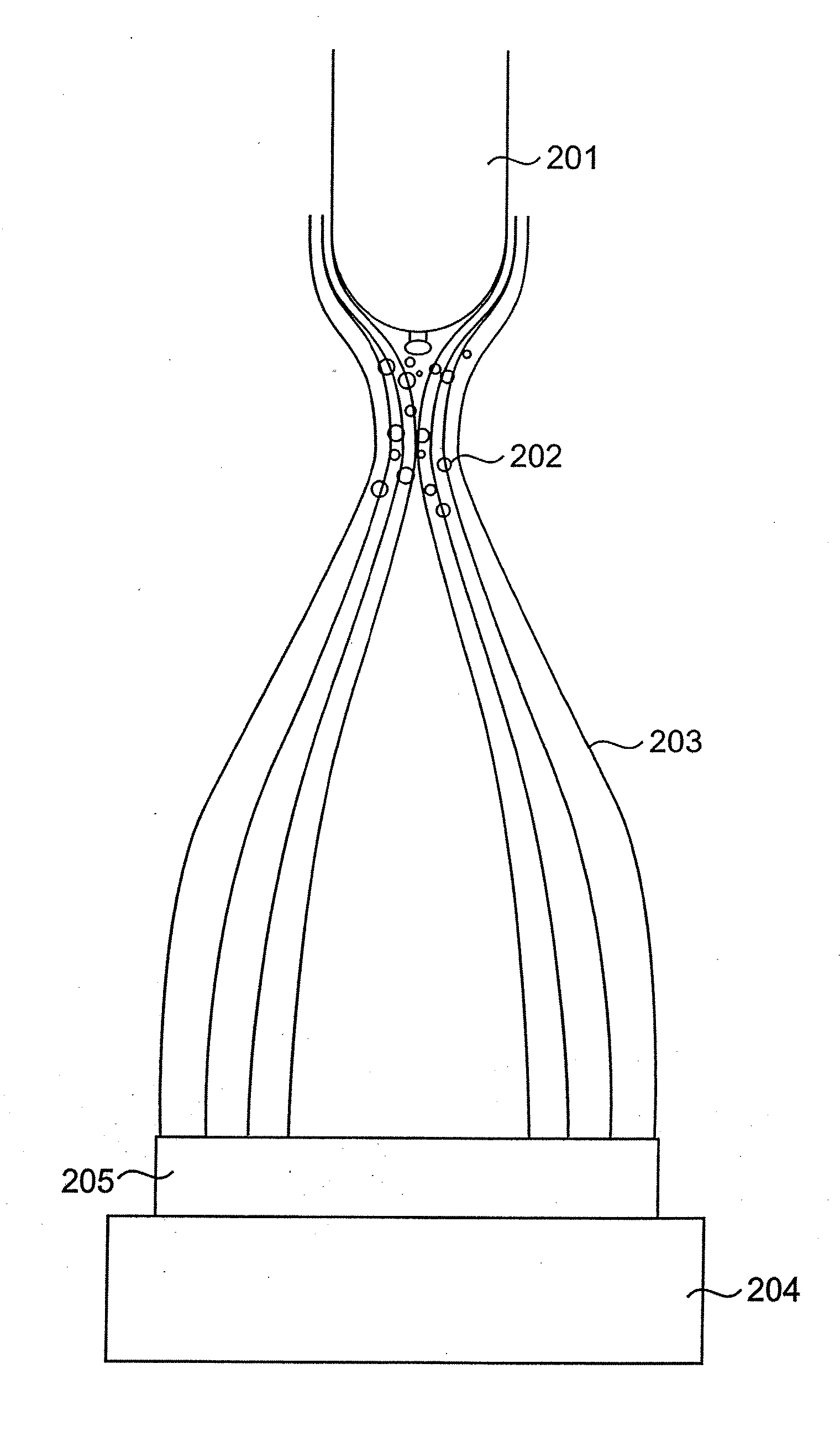

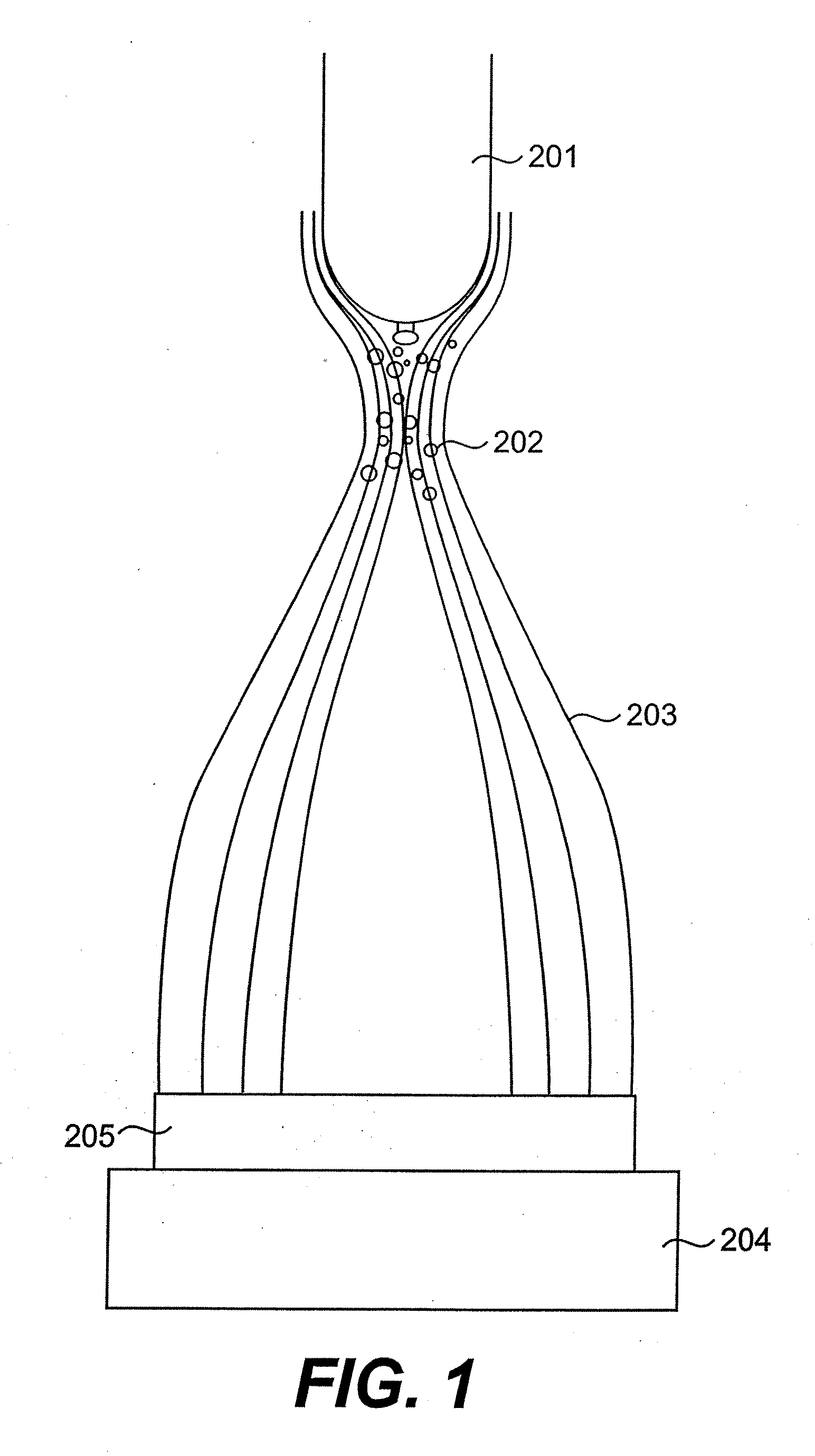

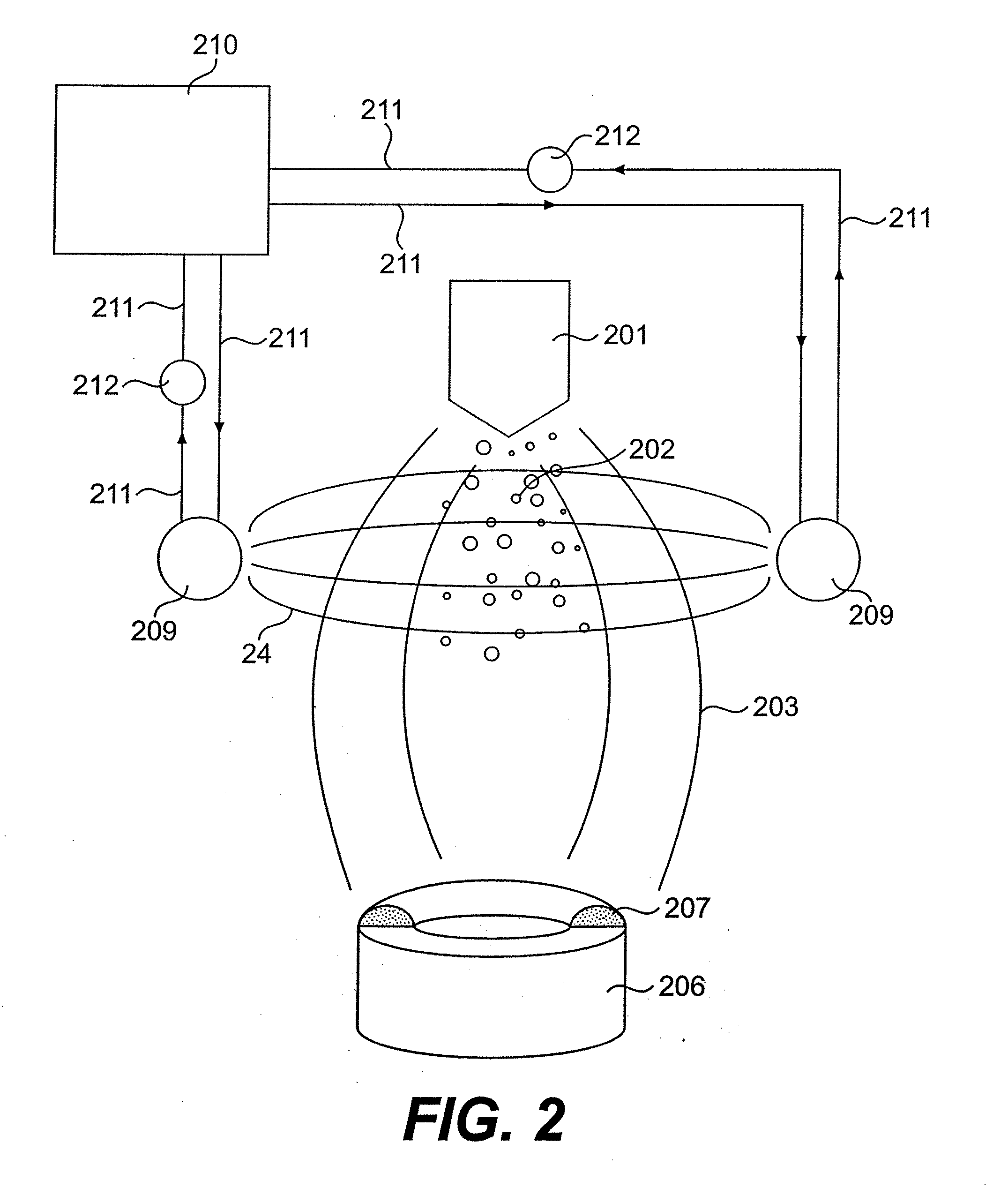

Image

Examples

example 1

[0197] Clean metal spraying experiments revealed that Wood's metal could easily be charged positively or negatively. It was observed that as the melting point of the metal increased, the ability to positively charge the metal did not change or improved slightly, while the ability to negatively charge the metal decreased. It was determined that the metals were positively charged to about 78% of the Rayleigh limit.

[0198] This example demonstrates that as the temperature of the metal increases, the electron emission rate increases. Thus, the ability to positively charge the metal is unaltered or improved, while the ability to negatively charge the metal is reduced.

example 2

[0199] In this example, the feasibility of deflecting charged metal particles in a controlled and repeatable manner using an electrostatic field was investigated. To this end, molten metal particles comprising tin were positively charged and then passed within 2 cm of an electrostatically charged plate. The particle sizes were about 0.050 inches to about 0.250 inches. The polarity and magnitude of the charge on the plate was varied in different trials.

[0200] The results indicated that the positively charged plate repelled the positively charged particles and the negatively charged plate attracted the metal particles. The deflection characteristics versus the applied voltage are shown in FIG. 5 for the molten particles comprising tin.

example 3

[0201] In this example, a video tape data analysis was developed to analyze the results obtained in Example 2 to provide a statistically viable comparison between the video of the spray forming process with and without an electrostatic field applied.

[0202] An 8 mm video tape was digitized and replayed frame by frame on a high contrast NTSC video monitor. Each frame was judged as demonstrating good or poor collection efficiency based on three criteria. (1) Attenuation: If less than 80% of the particles directly targeted the preform then the frame was judged as demonstrating poor collection efficiency. (2) Bounce: If the particles appeared to bounce off the preform then the frame was judged as demonstrating poor collection efficiency. (3) Glow: If the particles produced a glow over the preform, it was indicative of a combination of poor attenuation and bounce off, and was judged as demonstrating poor collection efficiency.

[0203] After the frames were categorized as demonstrating goo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com