Bucket assembly for excavator

a technology of buckets and excavators, which is applied in the direction of mechanical machines/dredgers, soil shifting machines/dredgers, constructions, etc., can solve the problems of limited operational range, reduced productivity, and malfunction of holding operations, so as to reduce the number of processes for the target construction, reduce the cost, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Other objects and aspects of the invention will become apparent from the following description of the embodiments with reference to the accompanying drawings, which is set forth hereinafter.

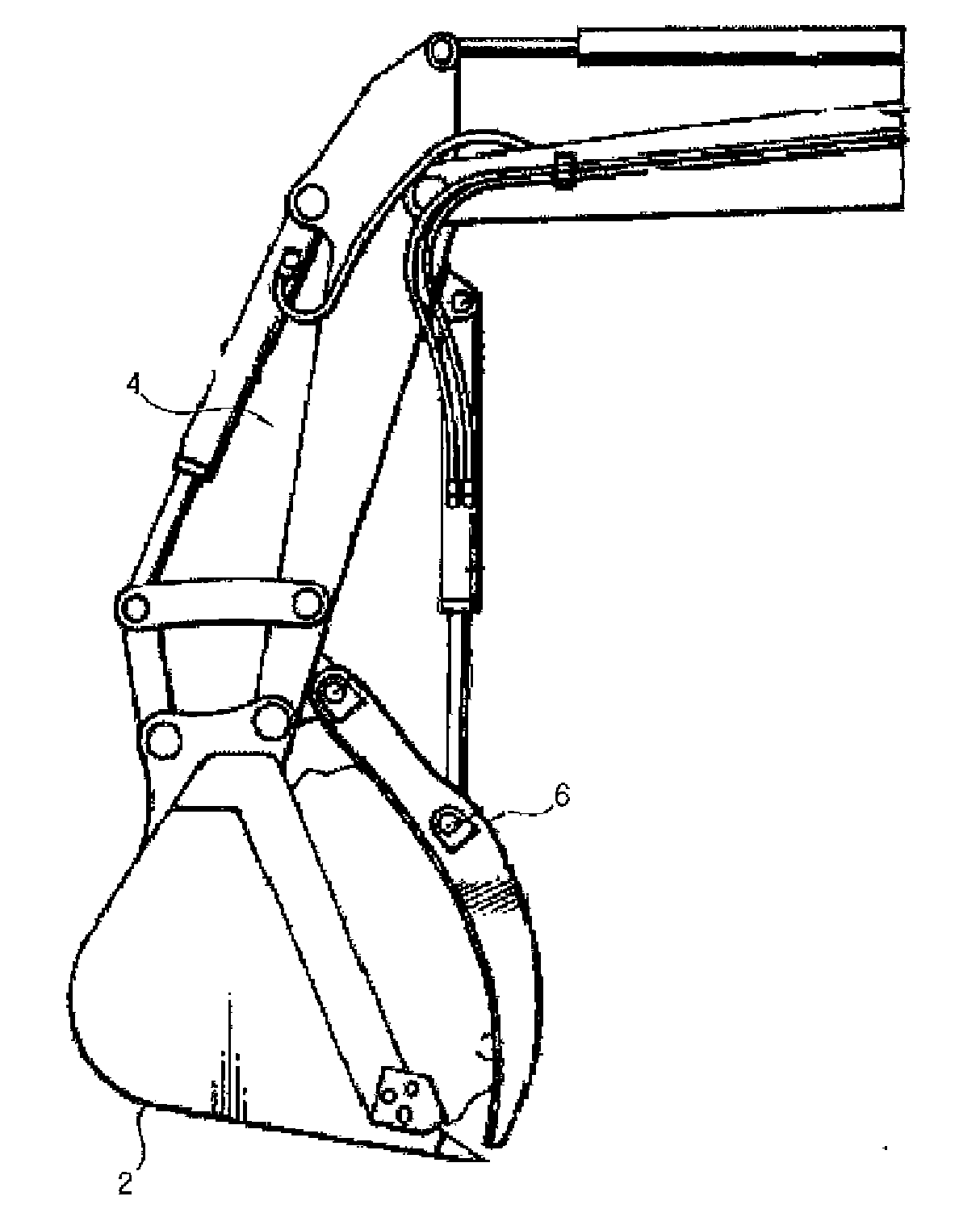

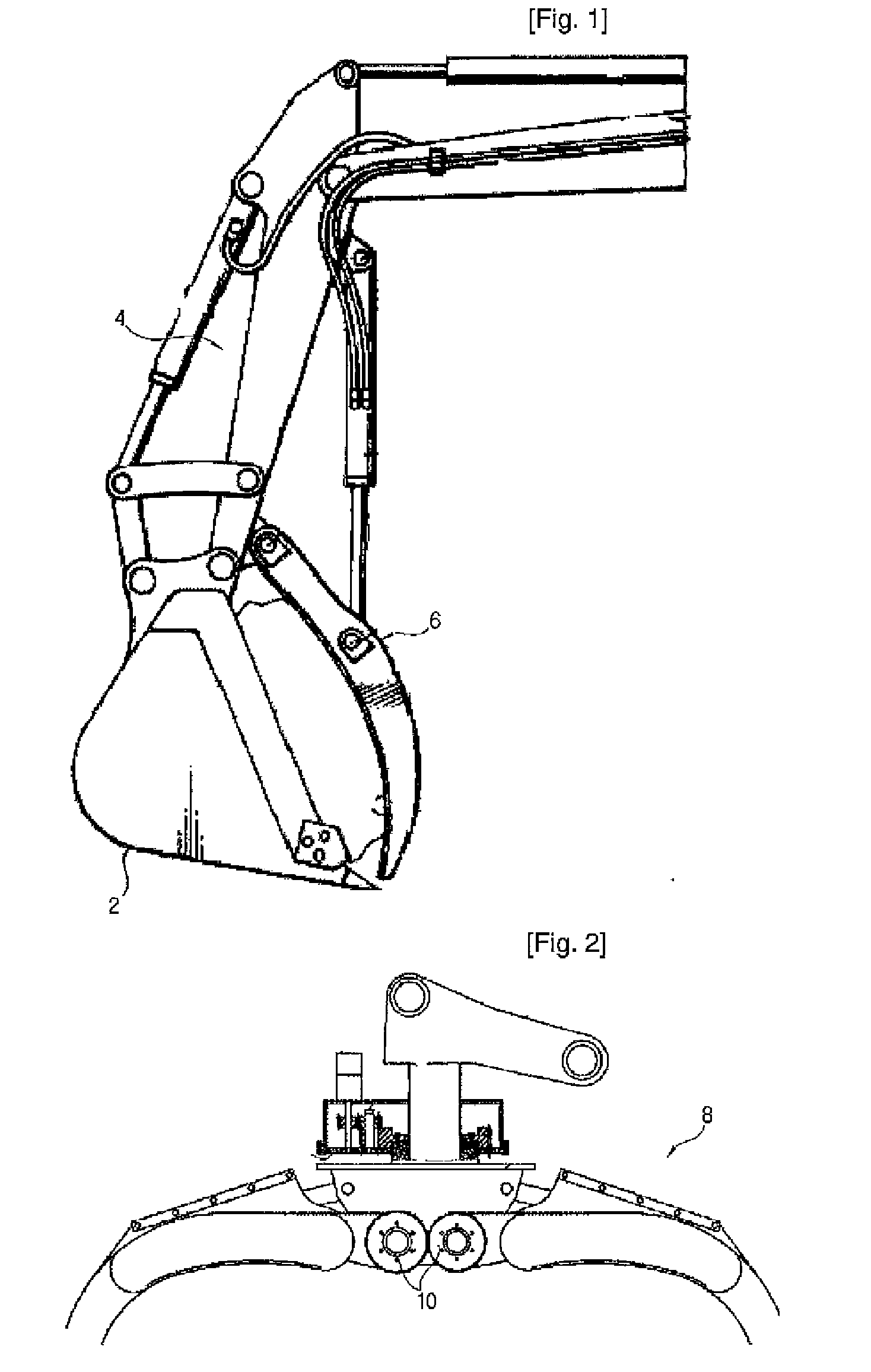

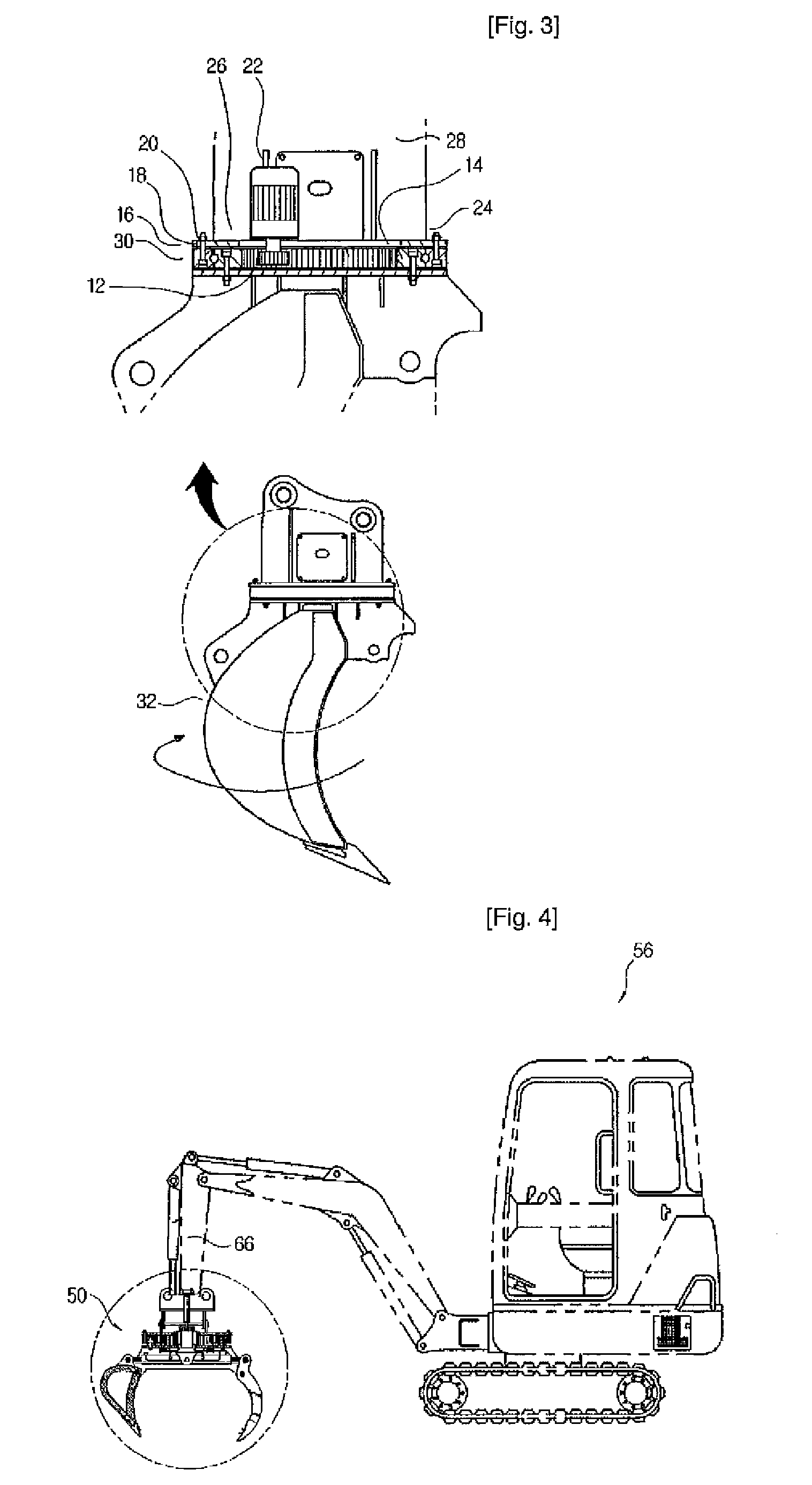

[0035]FIG. 4 is a view showing an excavator having a bucket assembling having a grappling member according to an embodiment of the present invention. FIG. 5 is a side cross-sectional view of a bucket assembly according to an embodiment of the present invention, and FIG. 6 is a cross-sectional view of FIG. 5 taken along a line A-A.

[0036] Referring to FIGS. 4 through 6, a bucket assembly 50 for an excavator 56 includes a bucket member 52 and a grappling member 54. The bucket assembly 50 includes a forward and backward tilting unit 58, a rotating unit 60, a driving unit 62 and a left and right titling unit 4.

[0037] The forward and backward titling unit 58 tilts a supporting plate 70 connected to a first hinge bracket 68 using a pin of a boom 66.

[0038] The forward and backward titling unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com