Steerable catheter using flat pull wires and having torque transfer layer made of braided flat wires

a technology of flat pull wires and torque transfer layers, which is applied in the field of catheters, can solve the problems of relatively large distances of steering force transmission, and the thin-walled introducer is more likely to collapse upon itself, so as to achieve greater flexibility, greater flexibility and control of the catheter, and reduced overall cross-section of the catheter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Flat Pull Wires

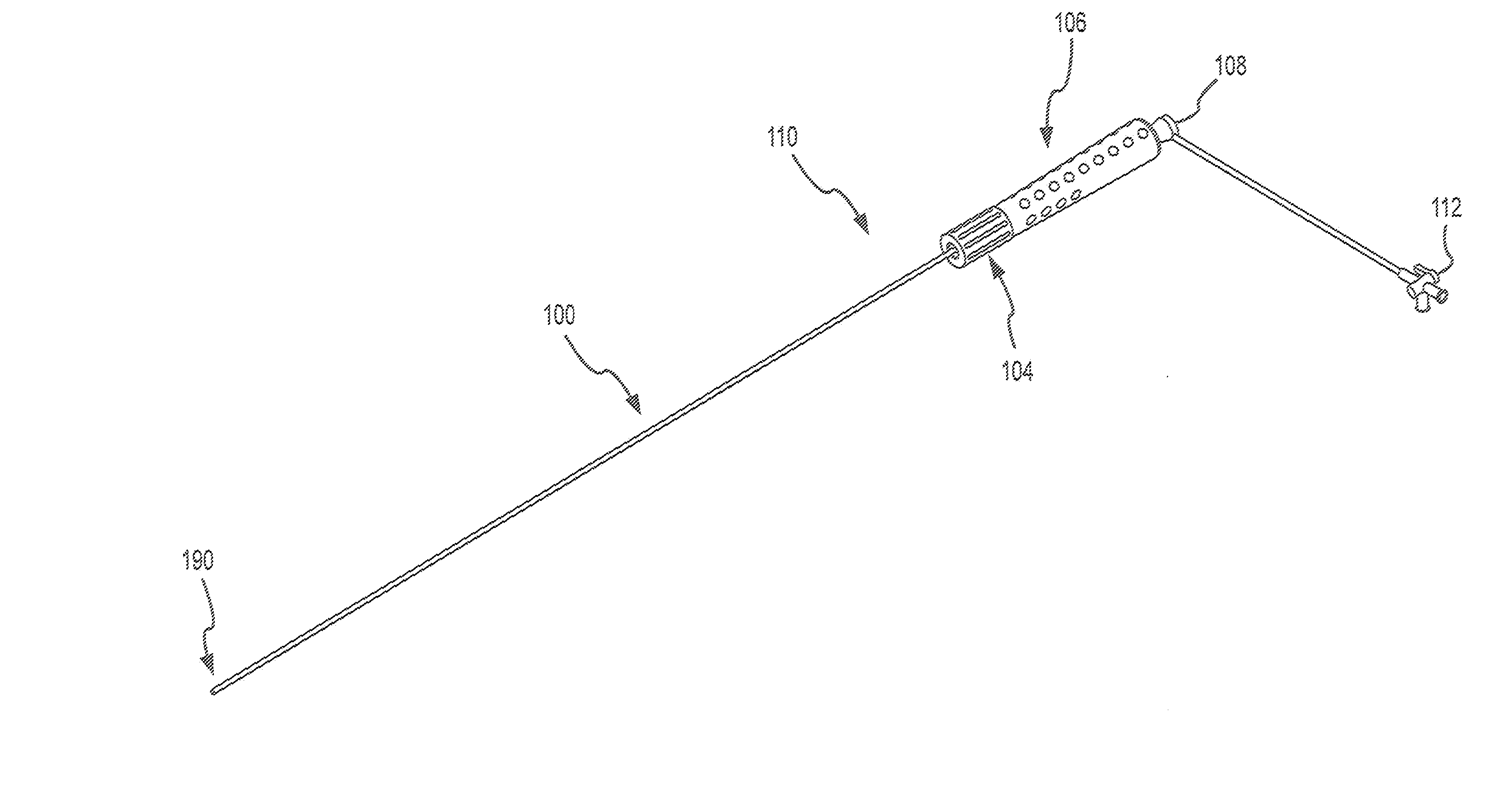

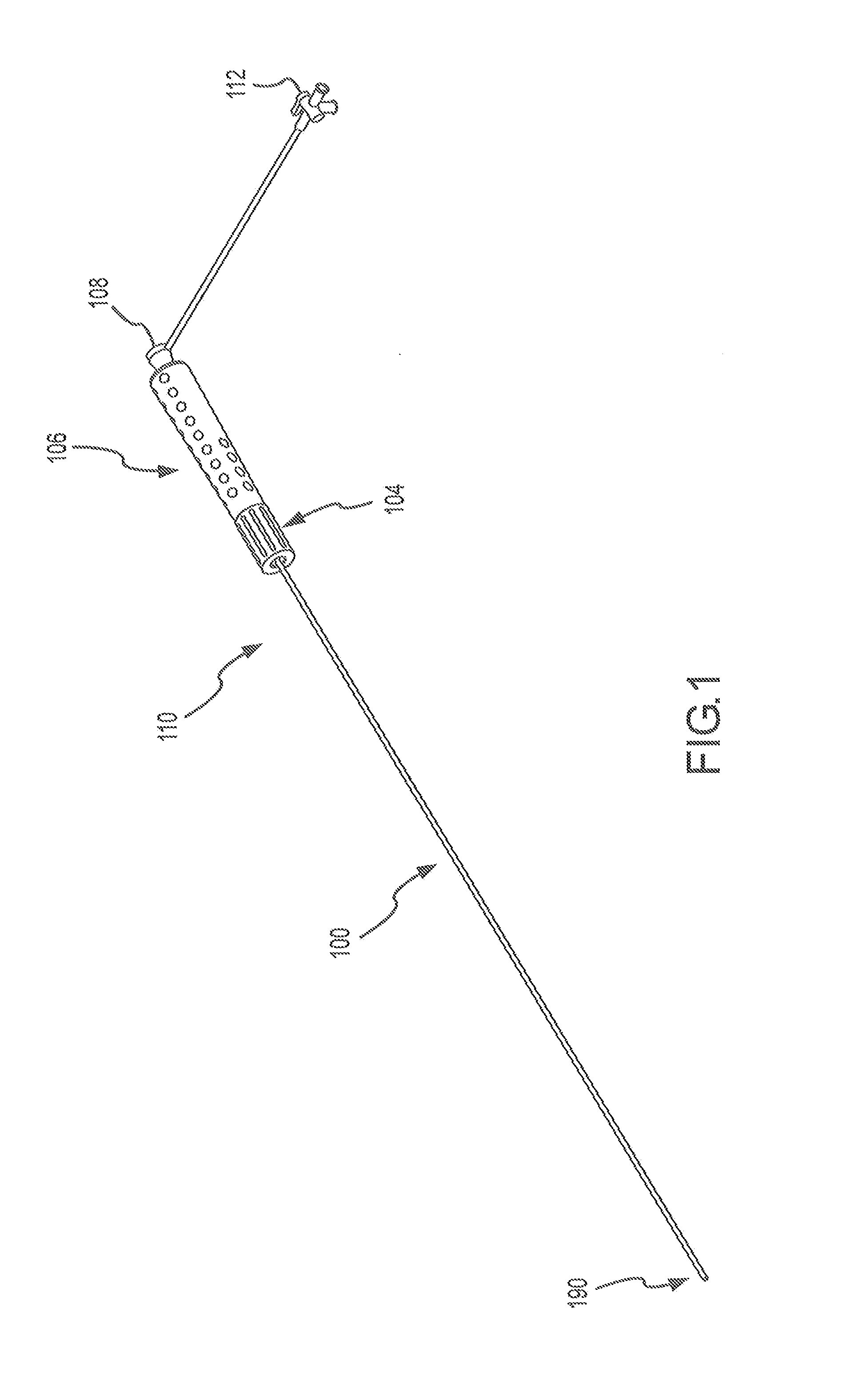

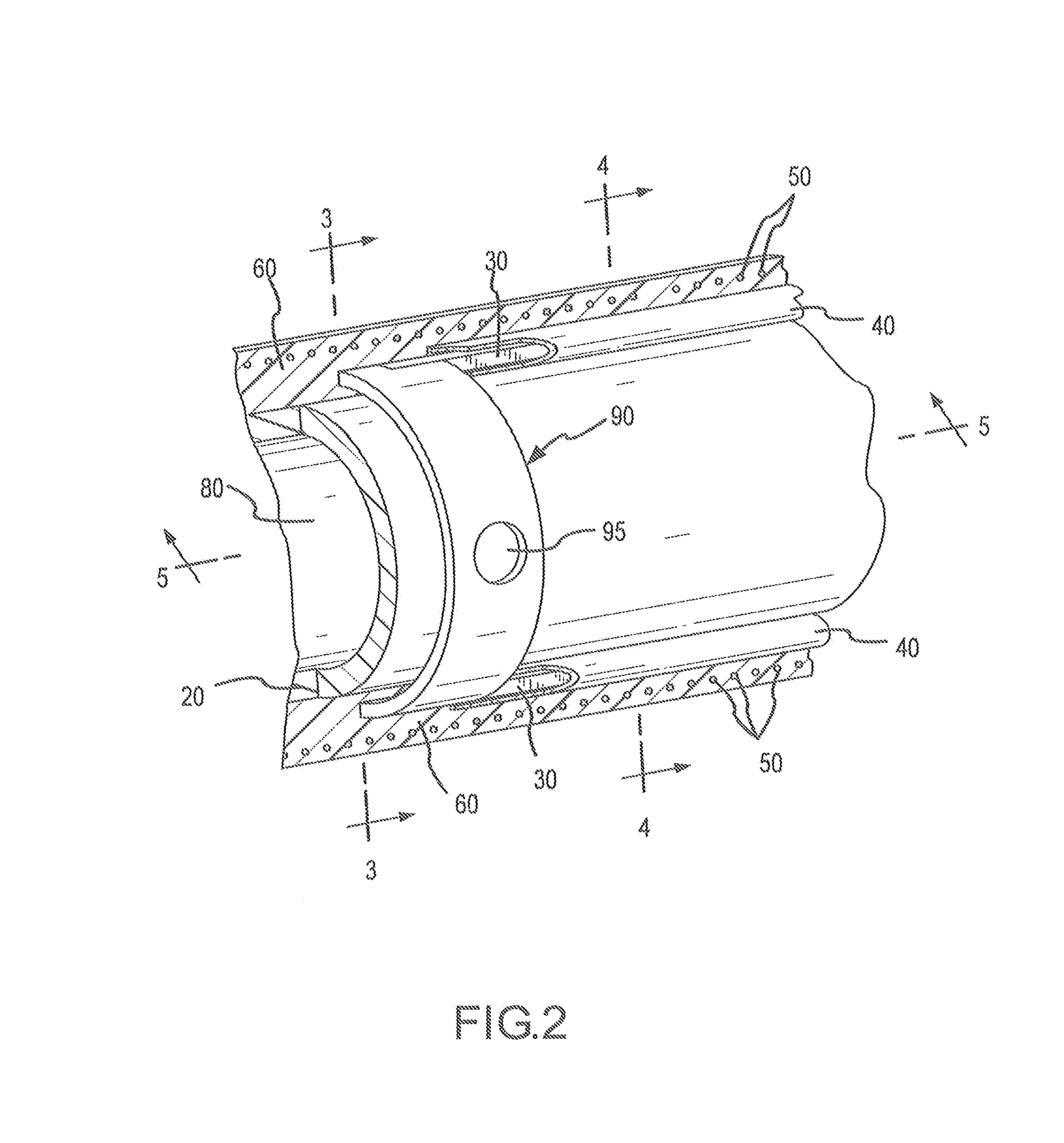

[0049] The present invention provides an improved steerable catheter that minimizes the overall outer dimensions by utilizing a variety of improved techniques. One technique is to utilize flat wire as the pull wires for the steerable catheter.

[0050] For purposes of this invention, a “flat wire” or a “flat pull wire” refers to a wire that is characterized by a cross-section that, when measured along two orthogonal axes, is substantially flat. A flat wire typically has a rectangular cross-section. For example, the rectangular cross-section may be approximately 0.004″×0.012″. The cross-section need not be perfectly rectangular. For example, the present invention contemplates a cross-section of the flat wire may be oval, provided that the overall cross-section is generally flat. For example, a wire may be properly characterized as a flat wire if it has a cross-section that is measured X in one direction and at least 3X in a second direction generally orthogonal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com