Nested Packaging For Central Vacuum Cleaner

a vacuum cleaner and packaging technology, applied in the field of nested packaging of central vacuum cleaners, can solve the problems of excessive air-filled items, cumbersome handling of items such as this size, and high cost of shipping such items, so as to minimize the problem of handling and storage of conventional central vacuum cleaners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

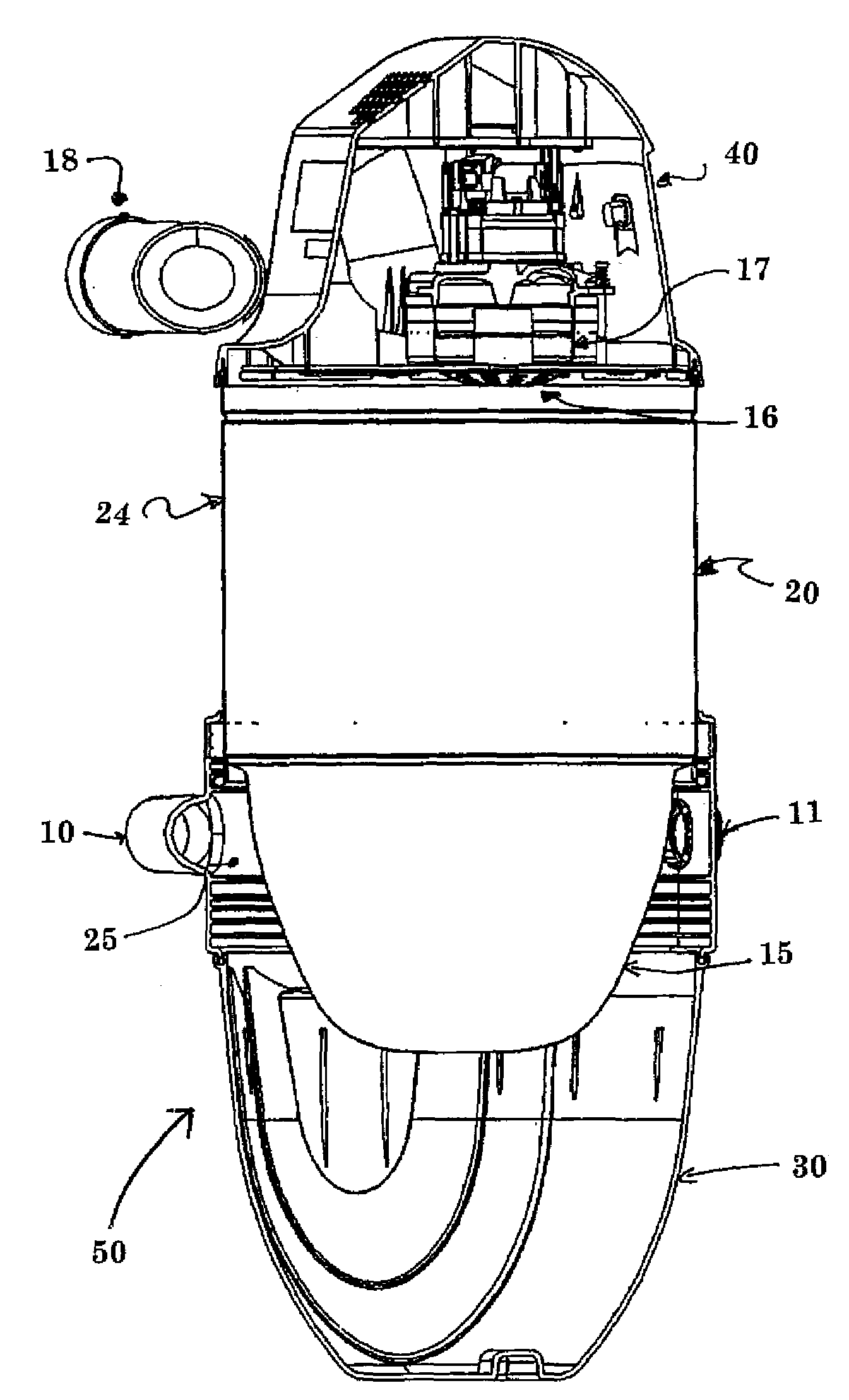

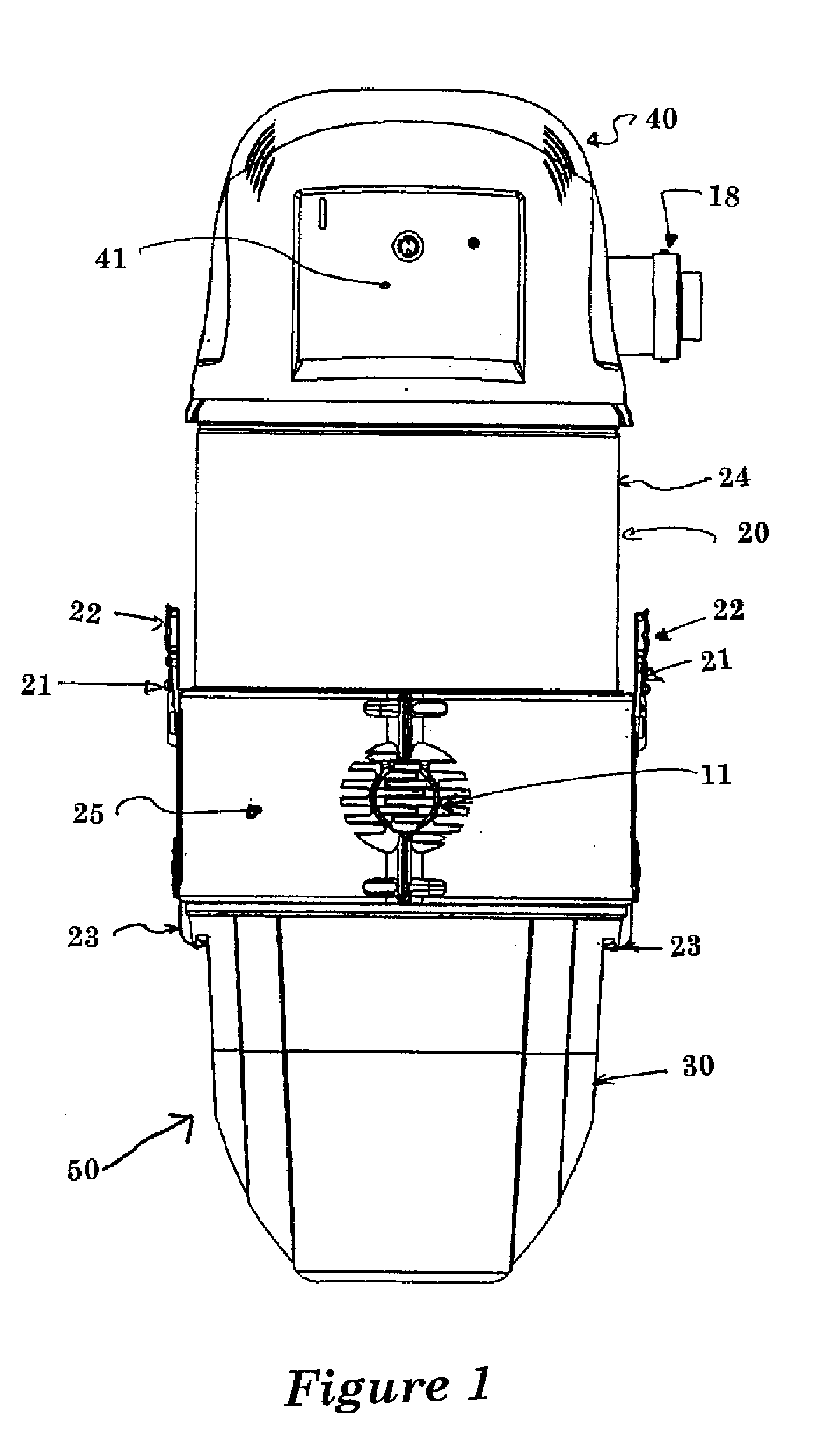

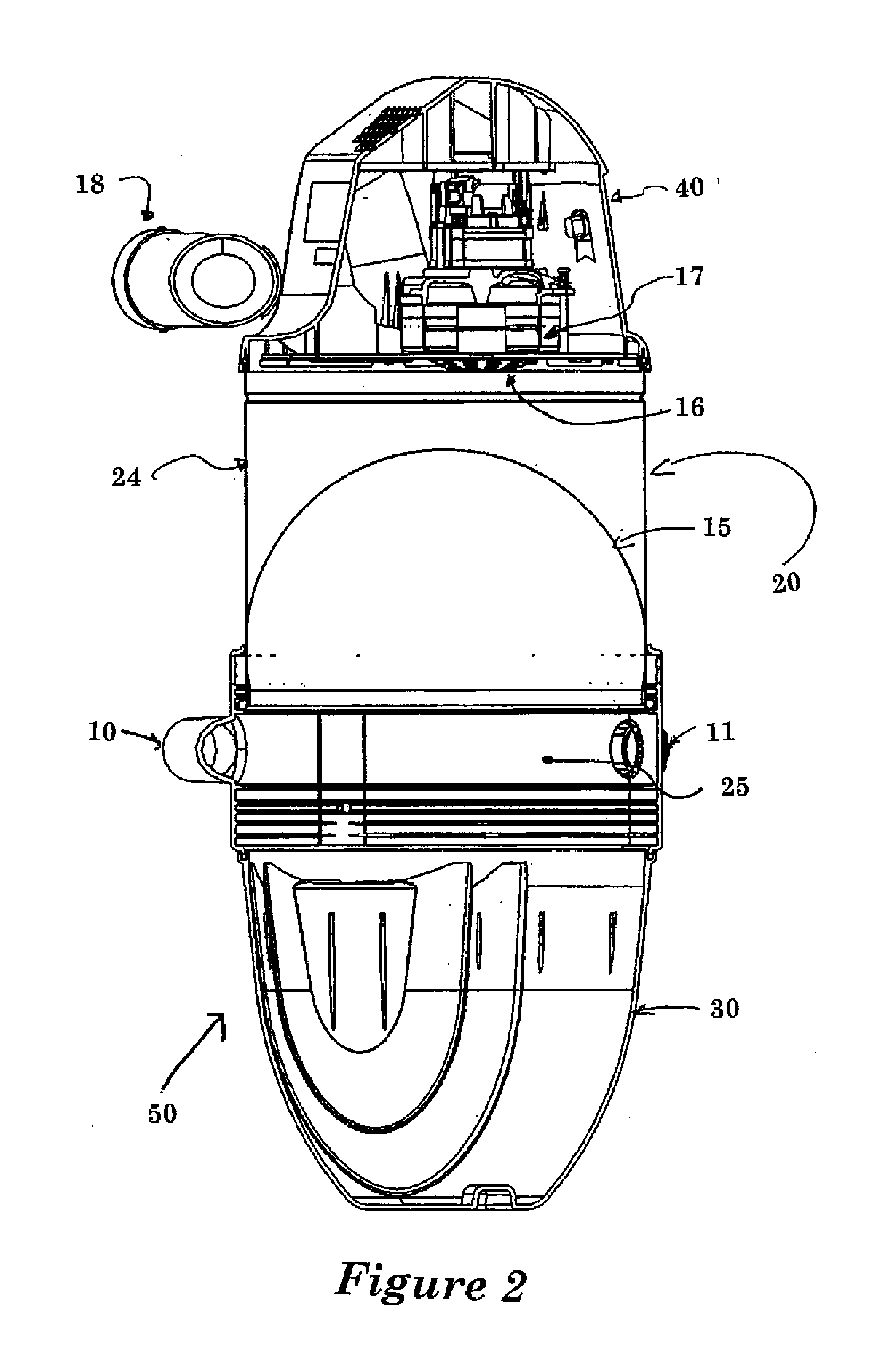

[0020]FIG. 1 is a front view of an assembled central vacuum power unit 50 according to the present invention. Power unit 50 may be used in household or commercial applications. Power unit 50 has a cylindrical configuration, is approximately 12-16 inches in diameter and, when assembled, is approximately 40 inches in height. Power unit 50 comprises three separate, functional sections or components: a central body module 20, a dust bucket 30 attached below body module 20 and a motor module 40 attached above body module 20.

[0021]Since the components are essentially stacked one on top of the other, the assembled configuration of FIGS. 1-3 is referred to as the “stacked assembly”.

[0022]Body module 20 is the largest section of the power unit and is essentially a large cylinder or canister. As will be described below, the large empty volume of body module 20 is necessary to hold and accommodate inflation and deflation of a vacuum filter bag or media 15 attached therein. It comprises an uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com