Framed Opening Bracing System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]It is to be understood by a person having ordinary skill in the art that the present discussion is a description of exemplary embodiments only, and is not intended as limiting the broader aspects of the present invention. The following example is provided to further illustrate the invention and is not to be construed to unduly limit the scope of the invention.

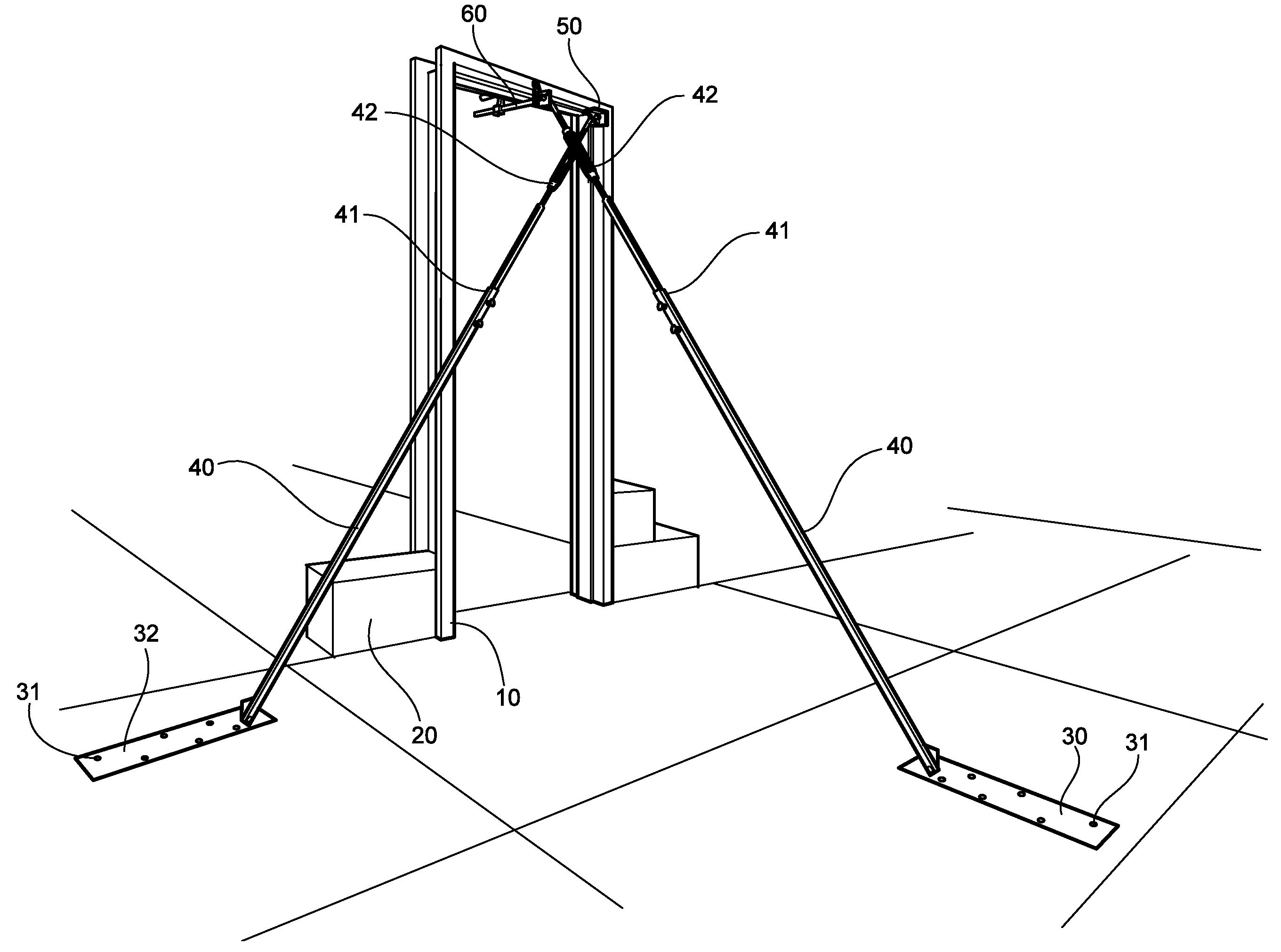

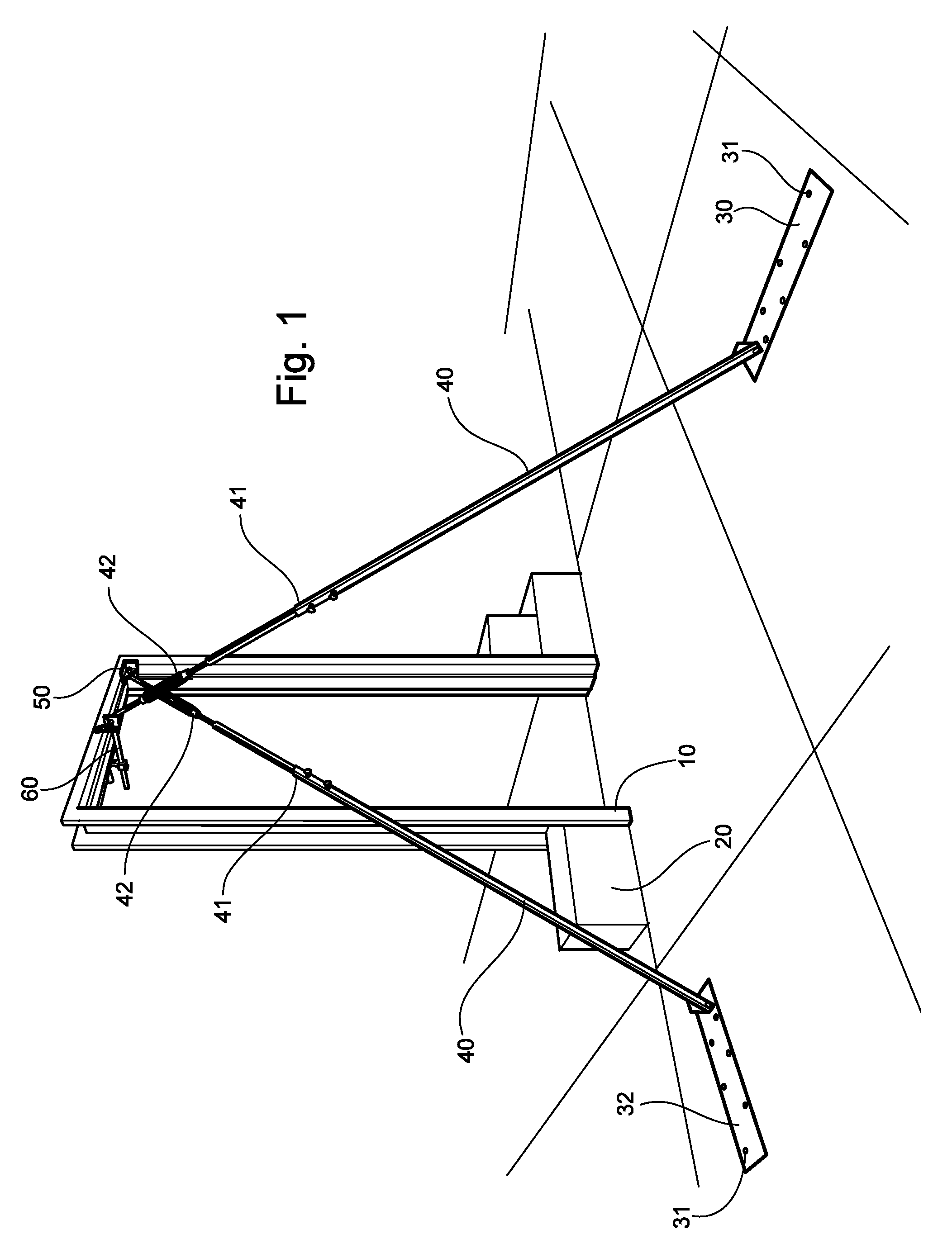

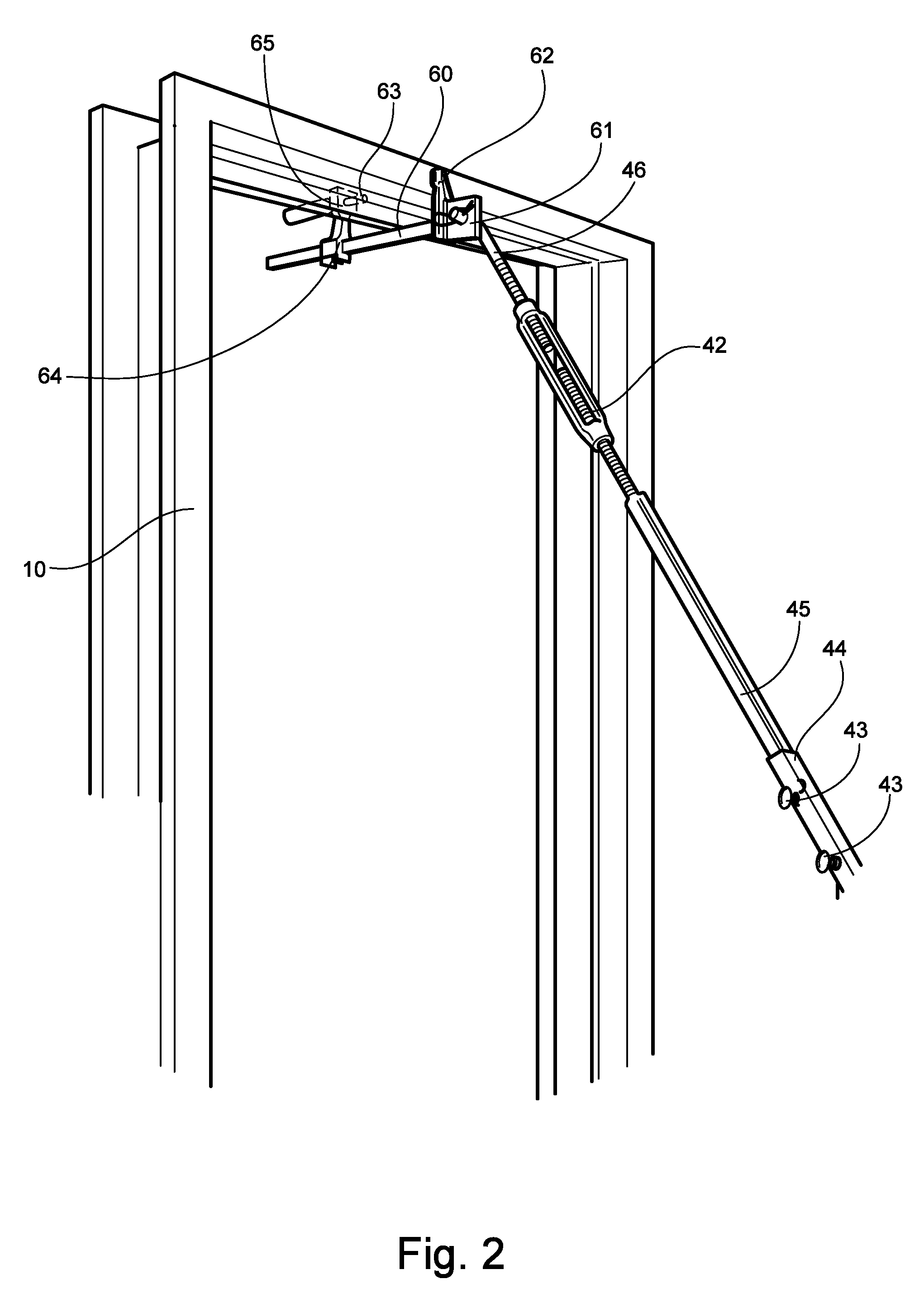

[0027]The present invention is a framed opening bracing system that utilizes one or more bracing arm devices to secure the frame during construction. The device of the present invention comprises a frame attachment means, a support arm (40), and a fixable base (30). The frame attachment means further consists of either a versatile clamp (60) or a corner support unit (50).

[0028]The versatile clamp (60) secures the bracing arm device to the frame (10). It is pivotally connected to the support arm (40) and temporarily attaches to the frame (10) by means of compression applied to the facial surfaces of the frame (10). This at...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap