Structure assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

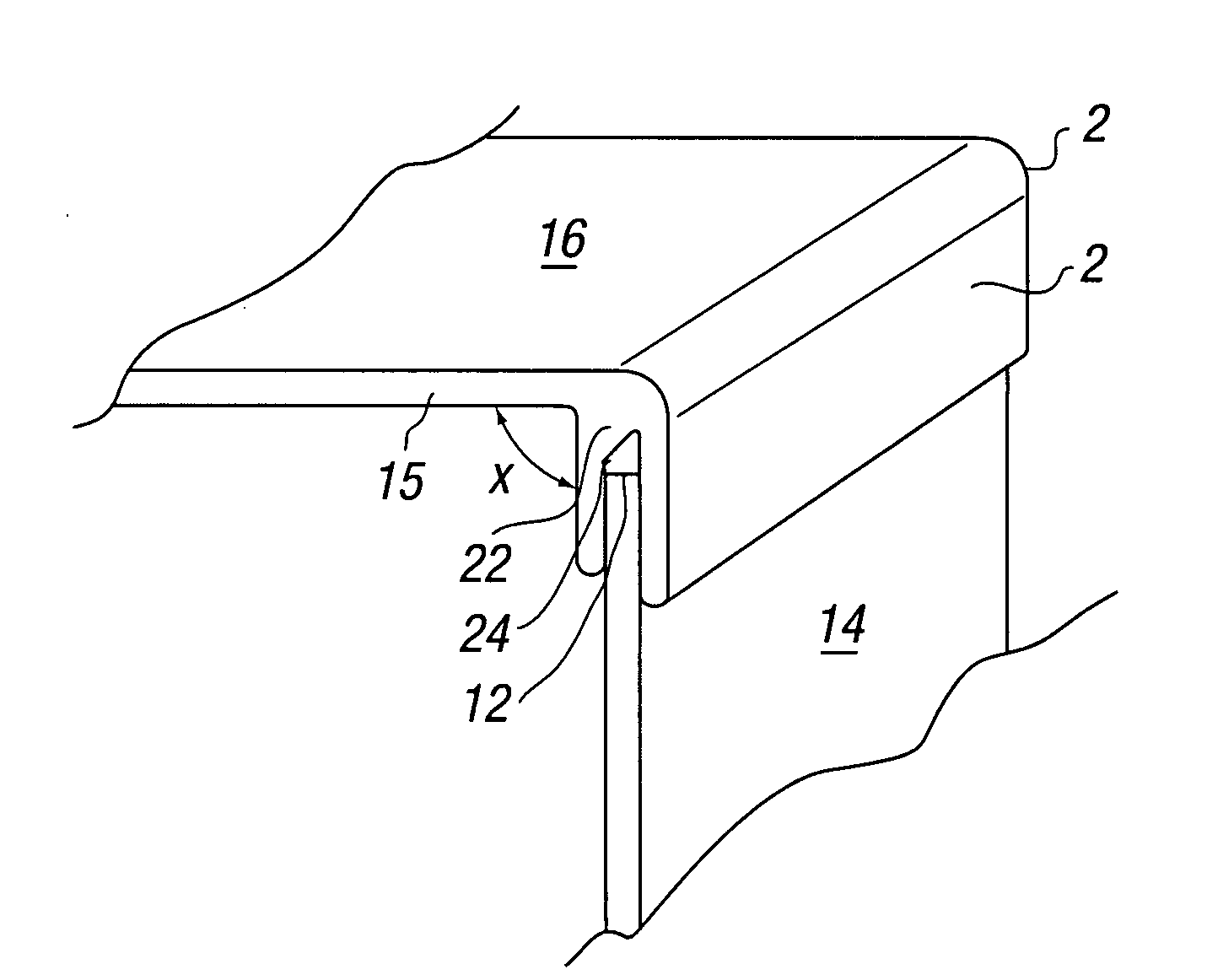

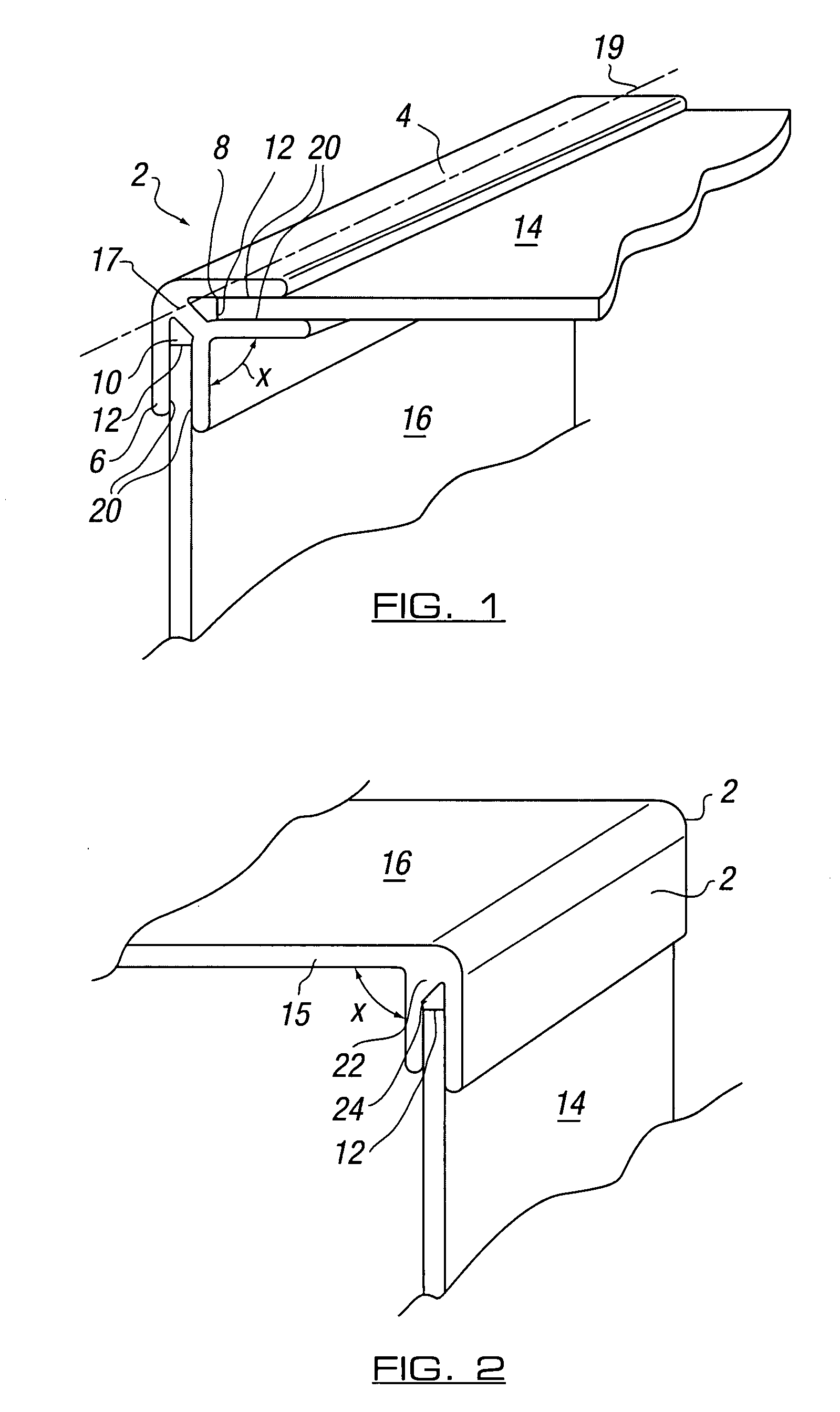

[0040]Referring now to FIG. 1, there is illustrated a connecting member 2 in accordance with one embodiment of the invention. As will be seen, the connecting member is elongate and, in this embodiment, includes first and second arms, 4, 6 which are angularly offset by an angle X, as illustrated. In this case, each of the arms includes a channel, 8, 10 respectively, which runs along the length of the same. The channel 8 of first arm 4 is shown receiving an edge 12 of a first panel 14 which is partially shown, and channel 10 of second arm 6 receives the edge 12 of a second panel 16 which is partially shown. The channels can be provided with retention means, which may be in the form of protrusions 20, which improve retention on one or more faces of the panel at the panel edge so as to improve retention of the panel within the channel. It will, therefore, be seen that by retaining the respective panel edges in the connecting member, the panels can be held in position and in position at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com