Portable toilet chemical recharge pumping system

a technology for toilets and toilets, applied in bathroom accessories, domestic applications, applications, etc., can solve problems such as significant and possibly severe damage, and achieve the effect of reducing the risk of damage, facilitating direct and controlled control, and ensuring the recharging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

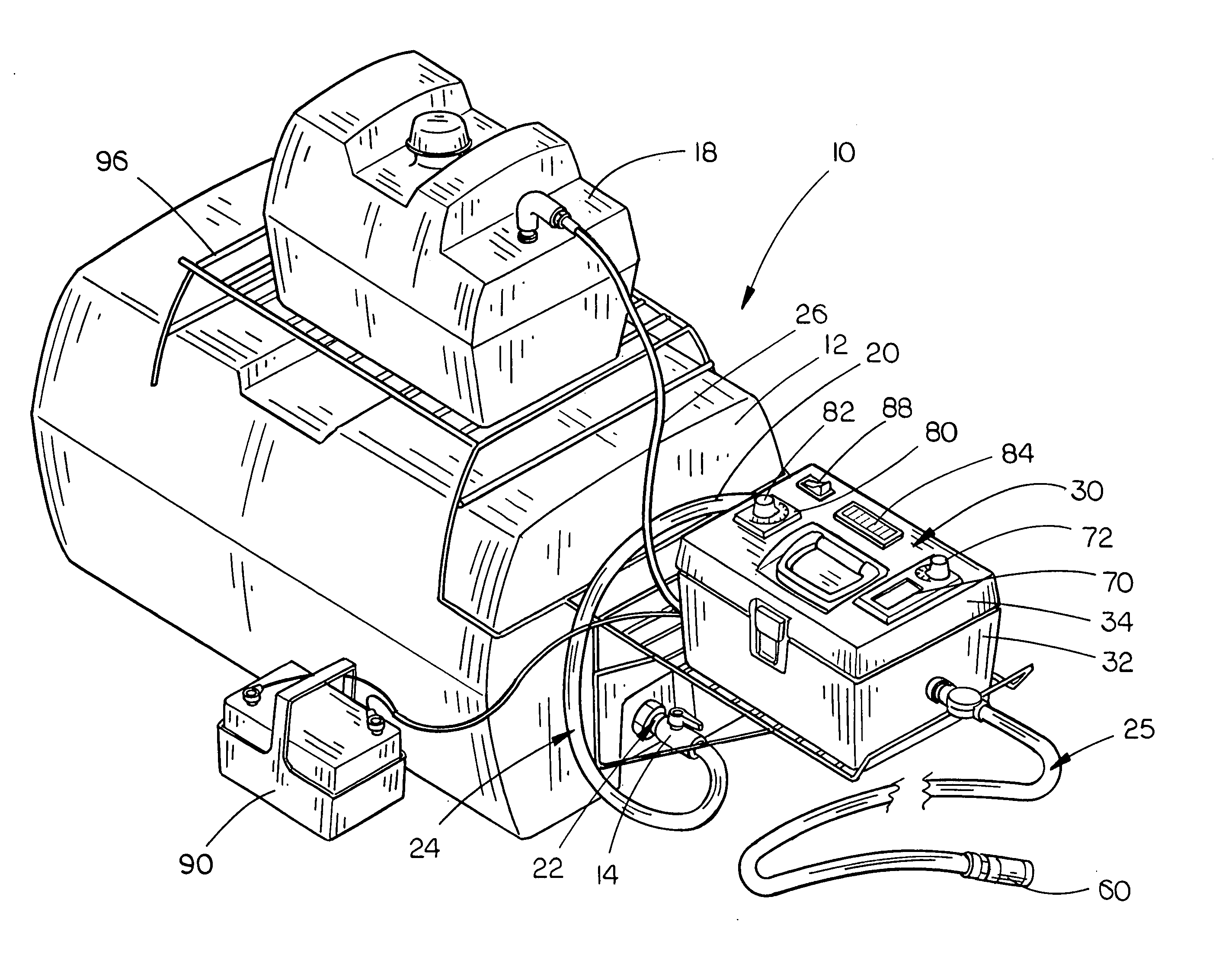

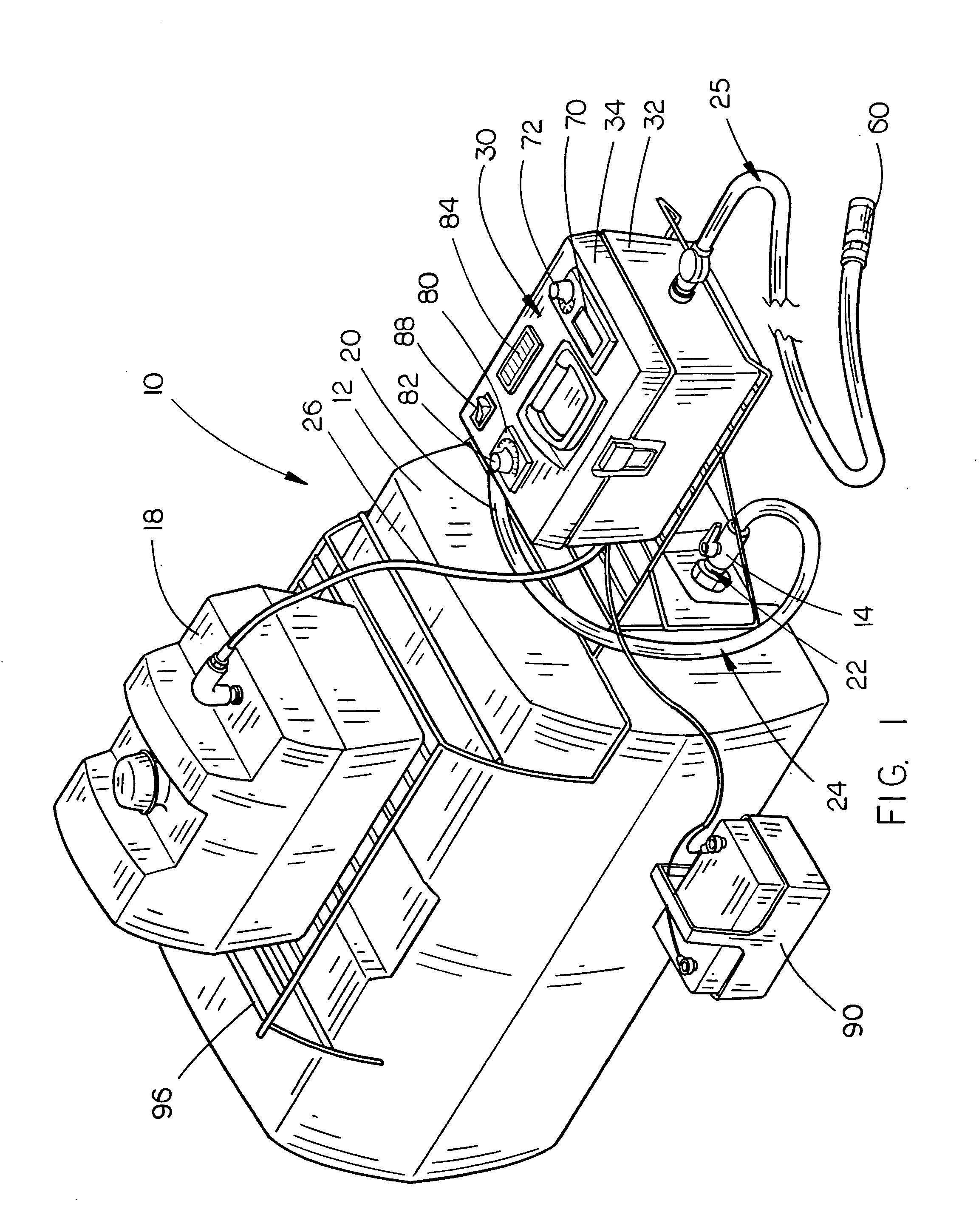

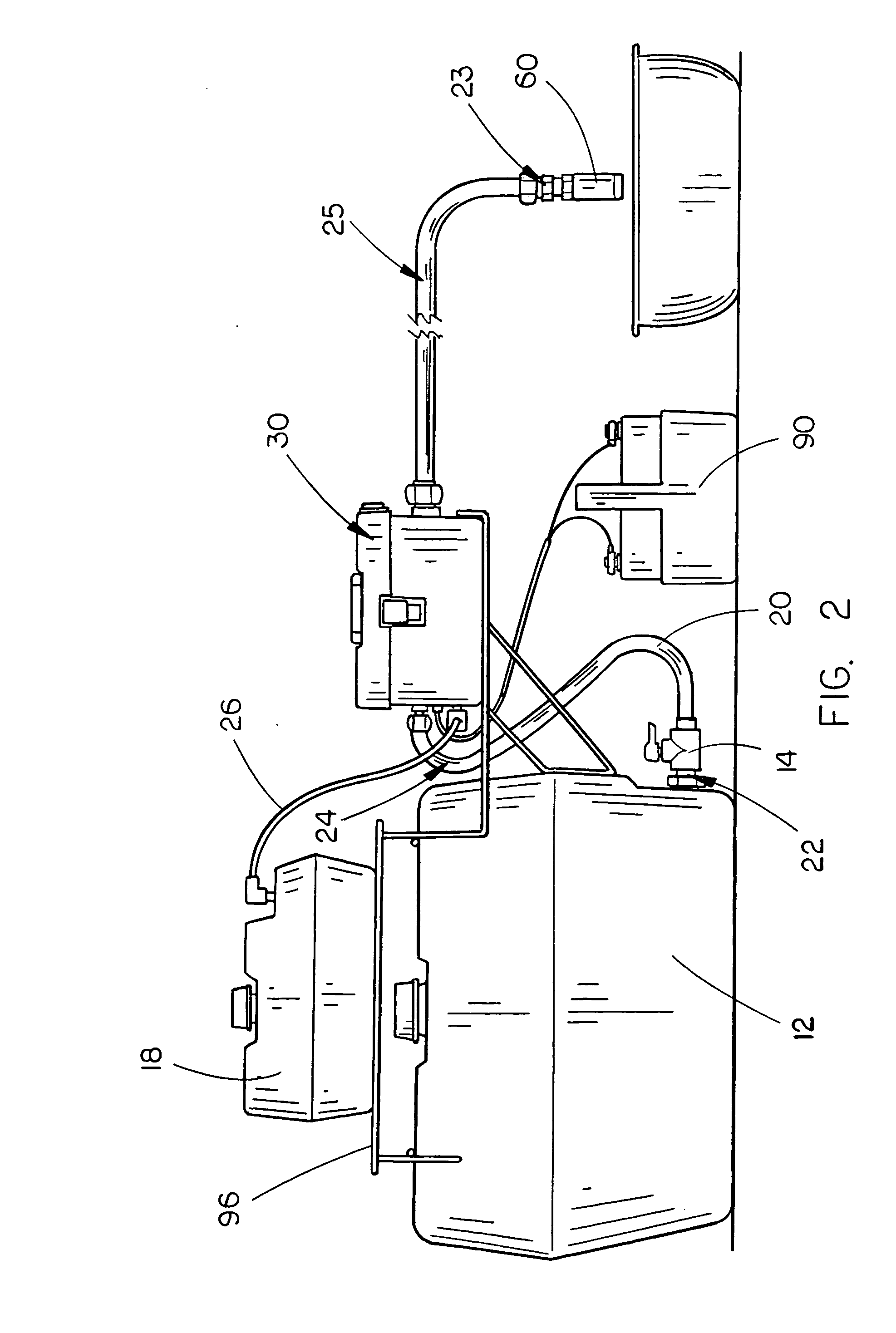

[0018]The portable toilet chemical recharge pumping system 10 of the present invention is shown best in FIGS. 1-4 as including a water reservoir 12 and a chemical reservoir 18, with the water reservoir 12 being of any appropriate size, shape and design, although it is expected that a large plastic or metal tank will be used for the water reservoir 12 of the present invention. Likewise, the chemical reservoir 18 may be or any desired size, shape or design, so long as the chemicals held within the chemical reservoir 18 are safely and securely retained therein until released into the pumping system 10 of the present invention. In fact, in many instances, the water reservoir 12 and chemical reservoir 18 would be carried on a vehicle such as a truck to provide a portable recharging system in accordance with the present invention as described below, although such usage is not particularly critical to the present invention.

[0019]Extending outwards from water reservoir 12 and in liquid tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com