Inflatable bag for bottles packaging

a bottle and bag technology, applied in the direction of packaging, sacks, flexible containers, etc., can solve the problems of limited impact absorption ability, inability to pack plural cylindrical bottles and provide suitable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

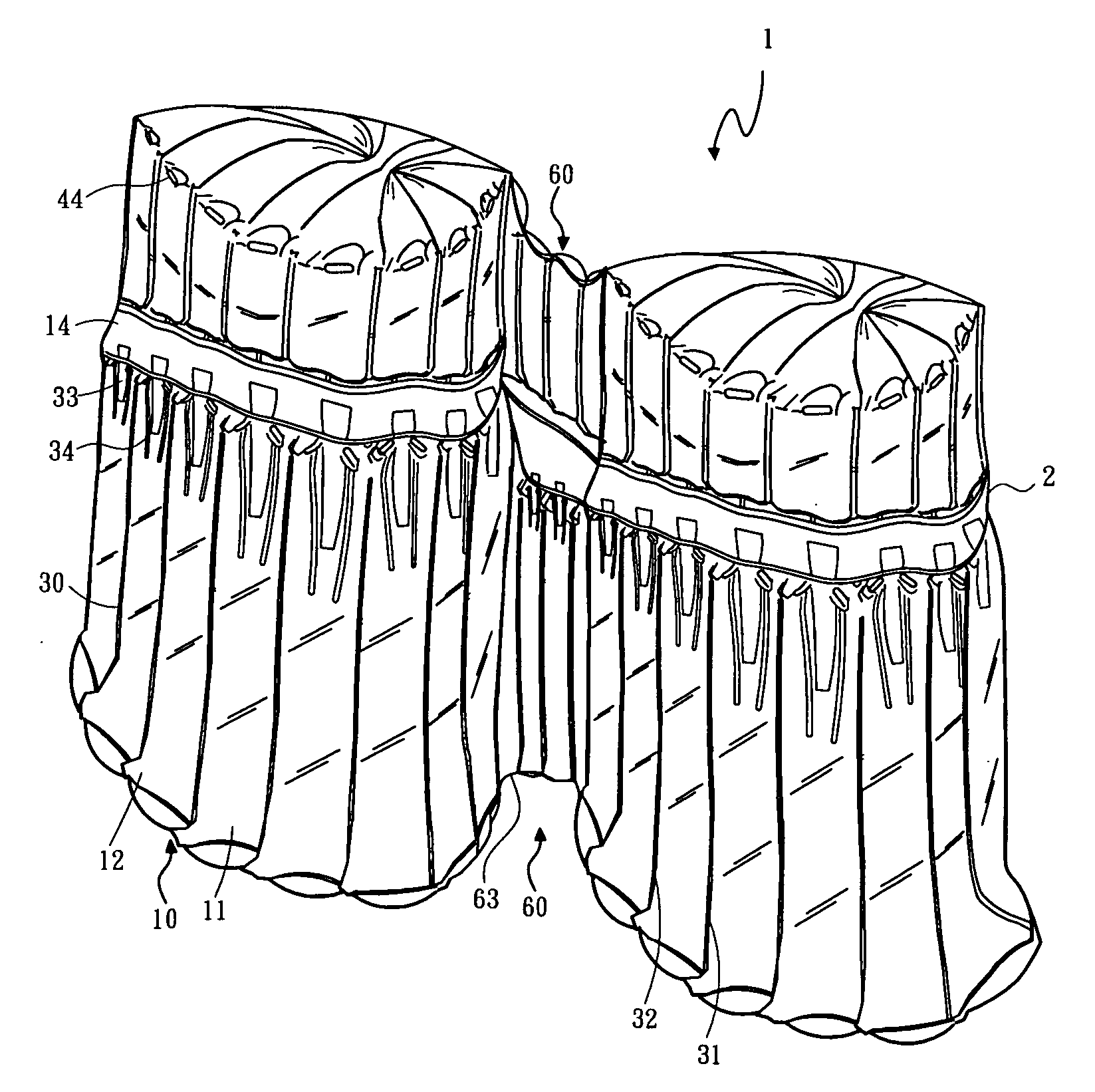

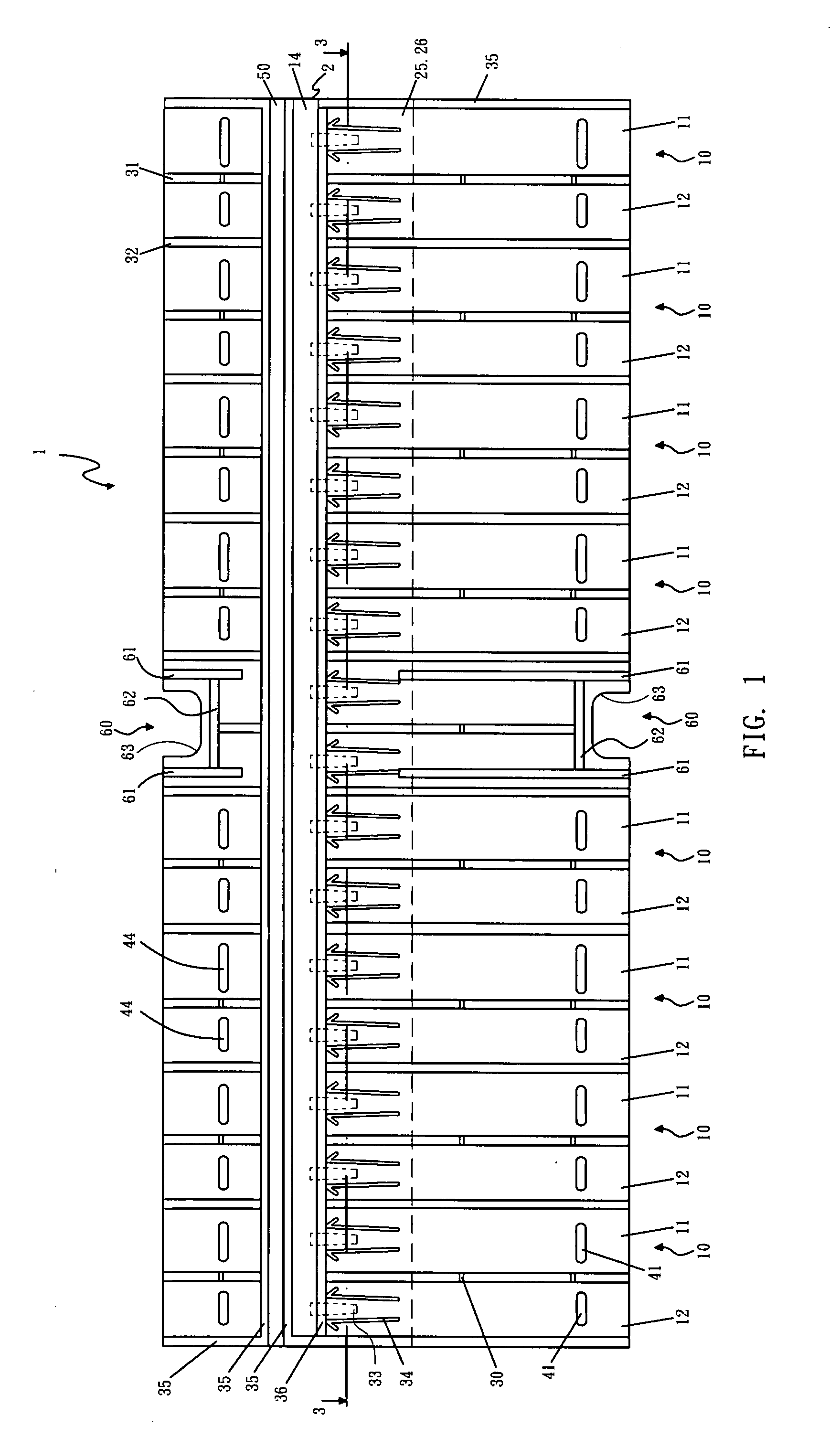

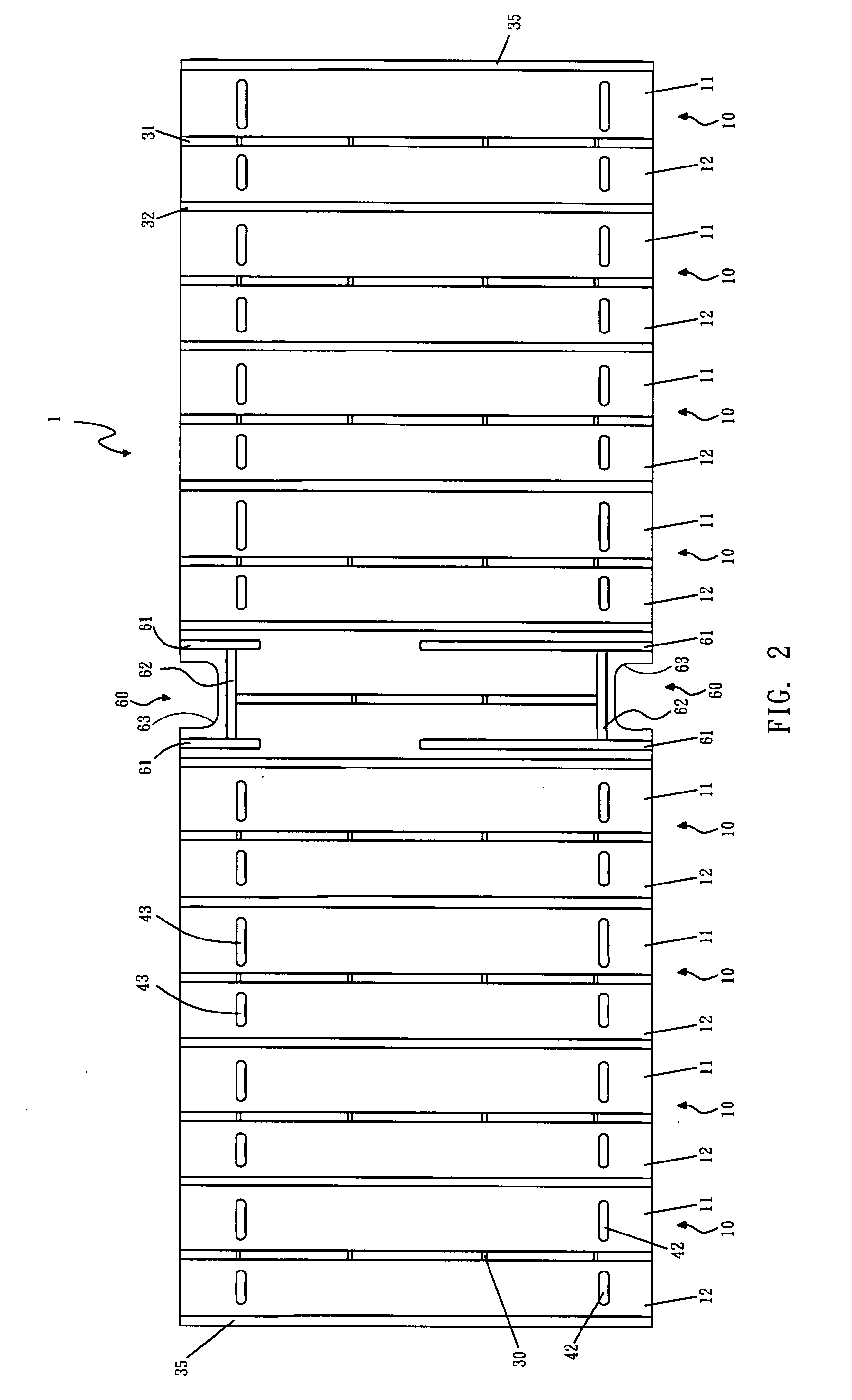

[0020]Referring to FIG. 1, the inflatable bag for bottles packaging of the present invention is composed of a plurality of gas pocket units 10. Each of gas pocket units 10 consist of a main gas pocket 11 having larger width and an auxiliary gas pocket 12 having smaller width. Welding line 31 sat between main gas pocket 11 and auxiliary gas pocket 12. Conduits 30 are installed along welding lines 31 by distance of 10˜15 centimeters, such that gas in the main gas pockets 11 and auxiliary gas pocket 12 can be flowed through conduits 30. However, gas pocket unit 10 is side by side with another, and welding line 32 is located in between, and there are no conduits installed on said welding line 32. The gas pocket units 10 are isolated between each and gas can not flow between each other. Thereby, when any main gas pockets 11 or auxiliary gas pockets 12 is broken, gas in which have left out, the other gas pockets still keep gas in it own. There is a gas inlet 2 on side of the inflatable ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com