Self Contained Foam Dispenser

a dispenser and self-contained technology, applied in the direction of mixers, liquid/fluent solid measurement, containers, etc., can solve the problems of clogging flow passages, affecting the quality of foam, so as to reduce waste, reduce element replacement costs, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

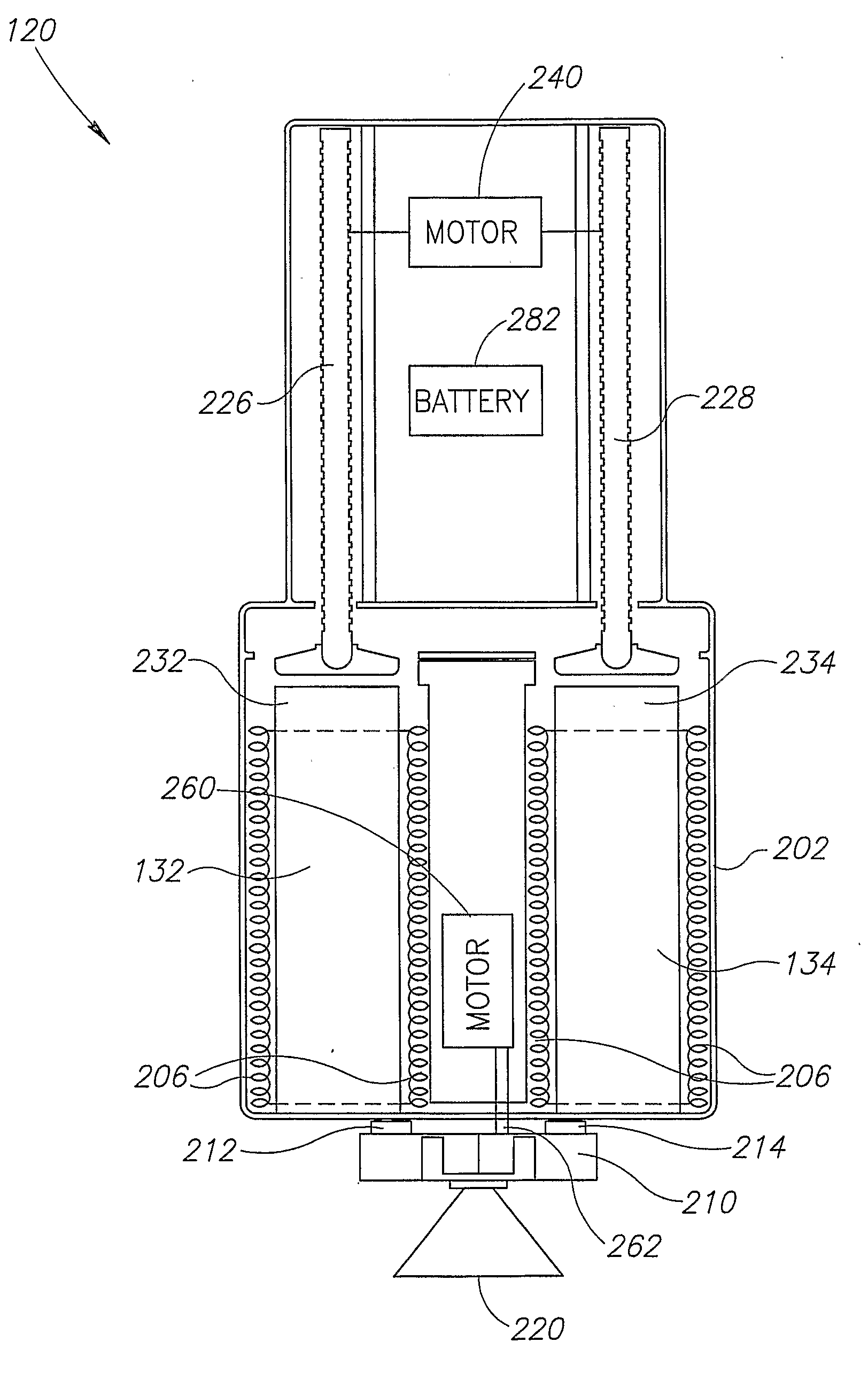

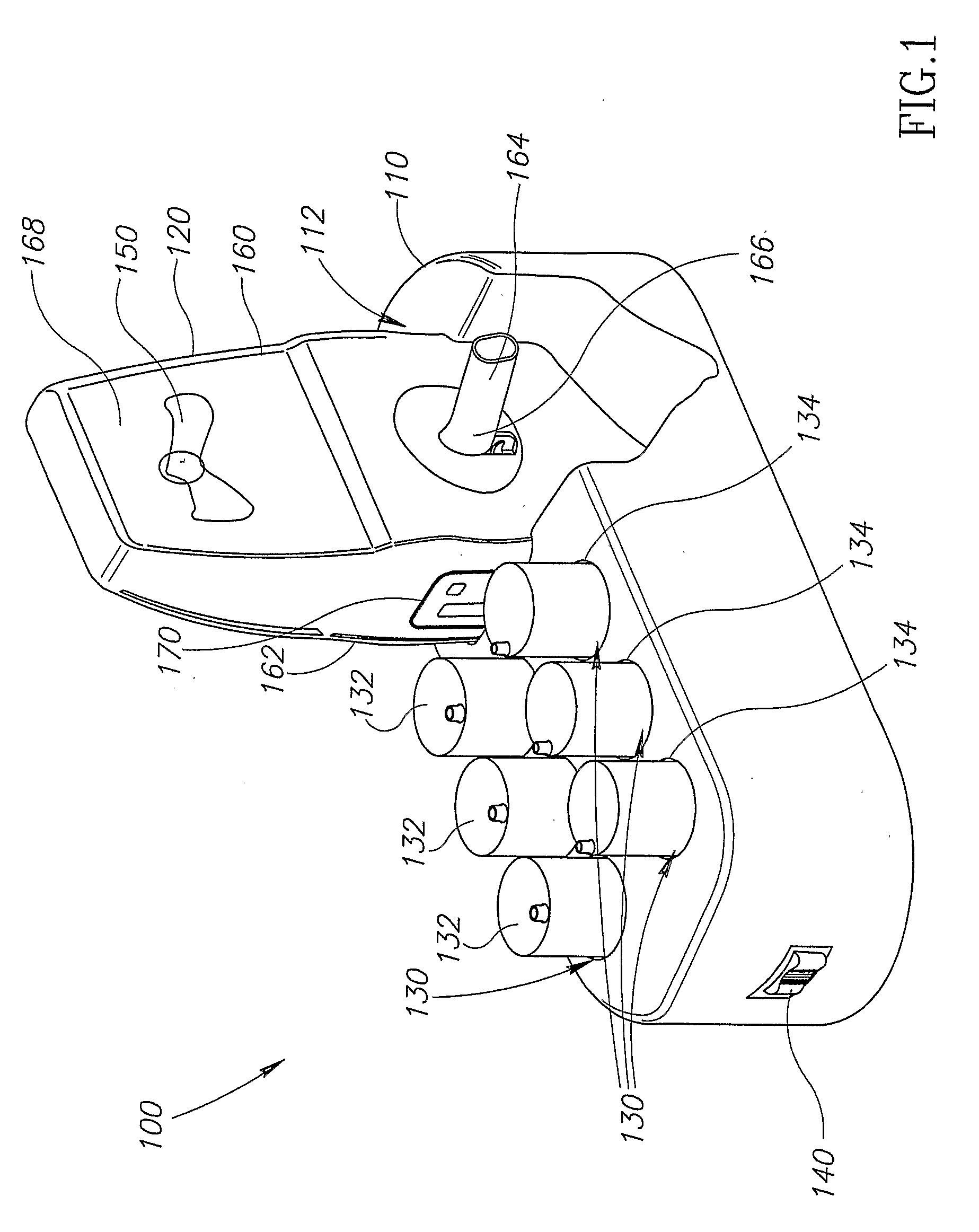

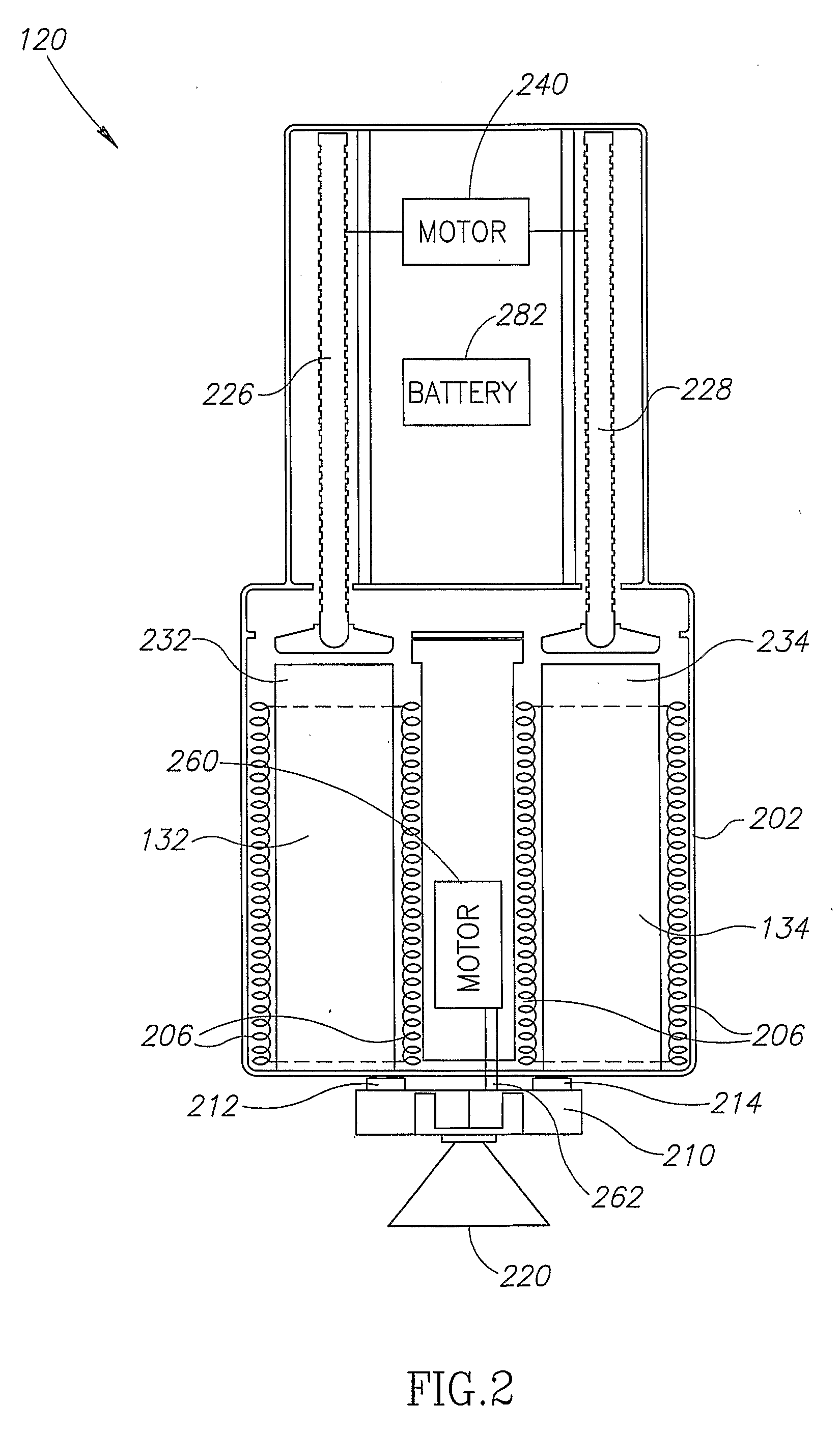

[0052]FIG. 1 is a schematic illustration of a foam generating and dispensing system 100, in accordance with an exemplary embodiment of the invention. System 100 comprises a base 110 which includes a recess 112 sized and shaped to receive a hand-held foam dispensing gun 120. Optionally, a battery (not shown) of gun 120 is charged when the gun is properly placed in recess 112. Base 110 optionally further includes a plurality of recesses 130 adapted to receive chemical containers, and heat the containers while they are in the recesses. In an exemplary embodiment of the invention, recesses 130 host containers 132 of a chemical A, e.g., and containers 134 of a chemical B. In an exemplary embodiment of the invention, chemical A comprises a polymeric isocyanate or a fluorocarbon, while chemical B comprises polyols, catalysts or flame retardants. It is noted, however, that system 100 is not limited to use with any specific chemicals and has advantages which are useful for mixing many chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com