Scrubbing device and roll sponge assembly used therein

a technology of scrubbing device and roll sponge, which is applied in the direction of carpet cleaners, cleaning machines, cleaning equipment, etc., can solve the problems of high degree of smoothness, extremely difficult to maintain a high level of cleaning quality at all times, and reliably remove, so as to achieve high-efficiency scrubbing, without further complicated devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

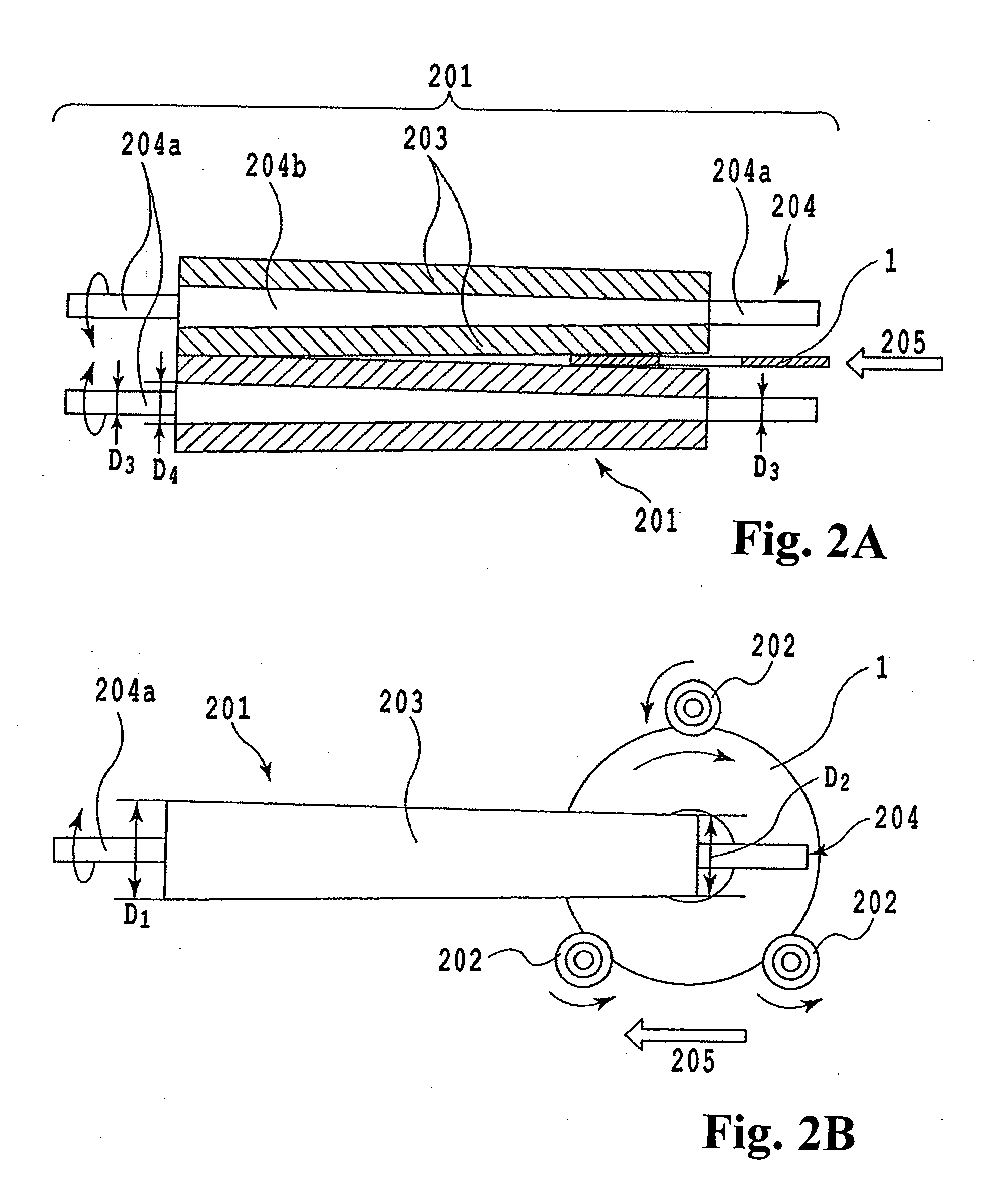

[0028]FIGS. 2A and 2B show schematic views of a scrubbing device according to a first embodiment of the present invention. FIGS. 3A to 3C show a substrate cleaning process performed by the scrubbing device. FIGS. 5A and 5B are views comparing the cleaning effects of the first embodiment and a conventional device. FIG. 6A is an exploded view of a roll sponge assembly used in the scrubbing device.

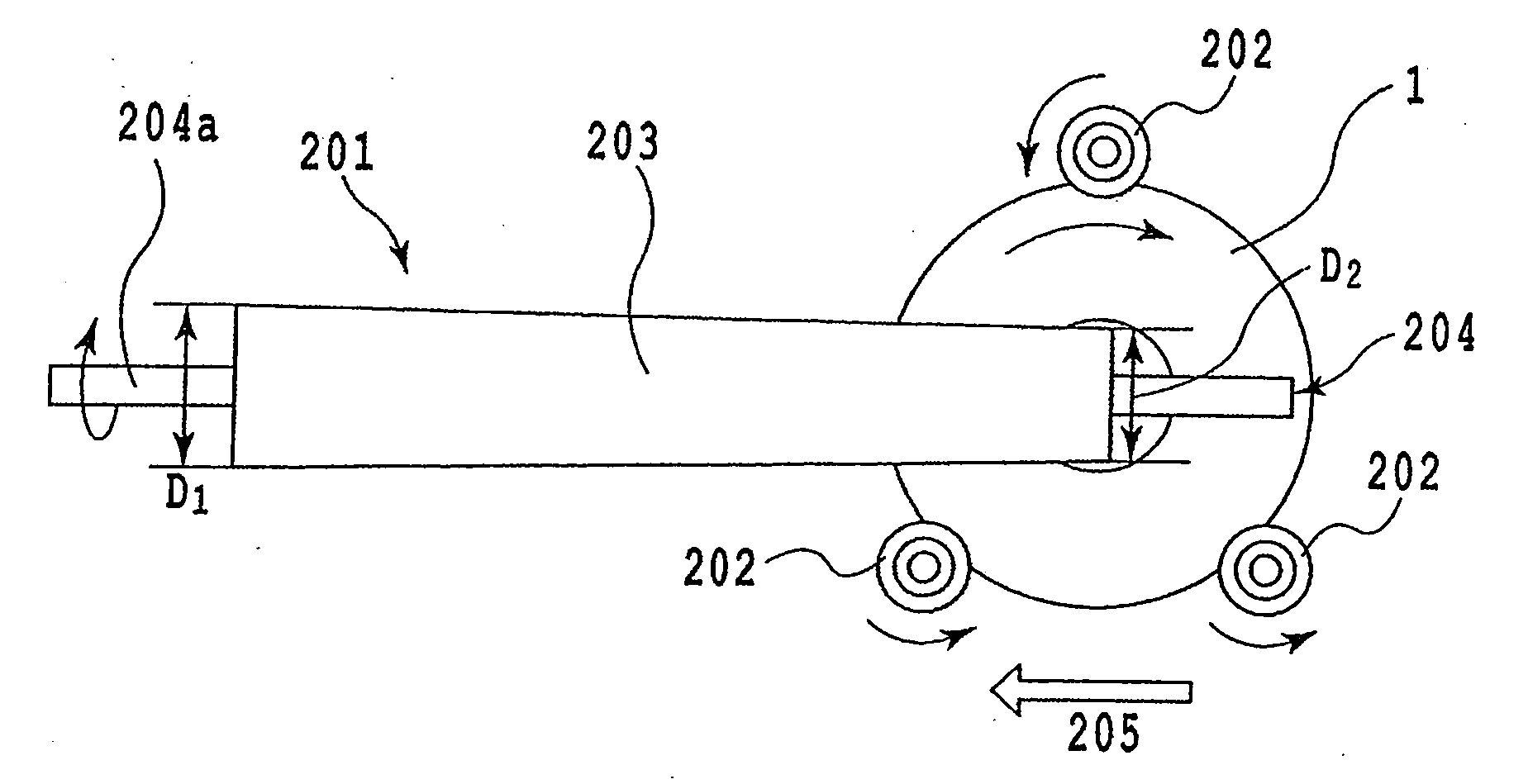

[0029]The scrubbing device of this embodiment basically comprises a plurality of rollers 202 for supporting and rotating a cleaning subject 1, and a pair of roll sponge assemblies 201 for cleaning the cleaning subject 1.

[0030]In the scrubbing device according to this embodiment, the cleaning subject 1 is an annular magnetic disk substrate. As is evident from FIG. 2B, the cleaning subject substrate 1 is supported vertically in a plurality of (three in this embodiment) support points around its peripheral edge by the plurality of (three in this embodiment) rollers 202. As shown in FIG. 2B, when...

second embodiment

[0045]FIG. 6B is an exploded view of a roll sponge assembly employed in a scrubbing device according to a second embodiment of the present invention.

[0046]This embodiment basically conforms to the first embodiment described above, but in consideration of the productivity of the expendable roll sponge 203, measures have been taken to adopt a conventional production method in which a constant-diameter roll sponge is simply cut for use. In other words, this embodiment differs from the first embodiment only in the structure of the roll sponge, and all other constitutions are completely identical to the first embodiment.

[0047]In this embodiment, as shown in FIG. 6B, a roll sponge assembly 401 includes a roll sponge 403 for cleaning a substrate and a support 404 for supporting the roll sponge 403.

[0048]The outer diameter of the outside contour of the roll sponge 403 according to this embodiment is constant in the lengthwise direction and equal to the minimum outer diameter D2 of the roll ...

third embodiment

[0054]FIG. 6C is an exploded view of a roll sponge assembly employed in a scrubbing device according to a third embodiment of the present invention.

[0055]This embodiment also conforms to the first embodiment described above, but improves the shape of the roll sponge and the support for fixing and supporting the roll sponge. Therefore, this embodiment differs from the first embodiment only in the structure of the roll sponge assembly, and is completely identical to the first embodiment in all other constitutions.

[0056]In this embodiment, as shown in FIG. 6C, a roll sponge assembly 501 includes a roll sponge 503 for cleaning a substrate and a support 504 for supporting the roll sponge 503.

[0057]Similarly to the roll sponge 203 of the first embodiment, the outside contour of the roll sponge 503 according to this embodiment has a conical trapezoid shape having an outer diameter that gradually increases from D2 to D1 in a right-left direction. A hollow hole 503c is formed in a central po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com