Egg Package Assembly

a technology for egg packages and egg shells, which is applied in the direction of packaging foodstuffs, packaging goods, containers preventing decay, etc. it can solve the problems of increasing the distribution cost of eggs, affecting the quality of eggs, so as to prevent accidental opening of eggs and prevent tampering of eggs. , the effect of high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

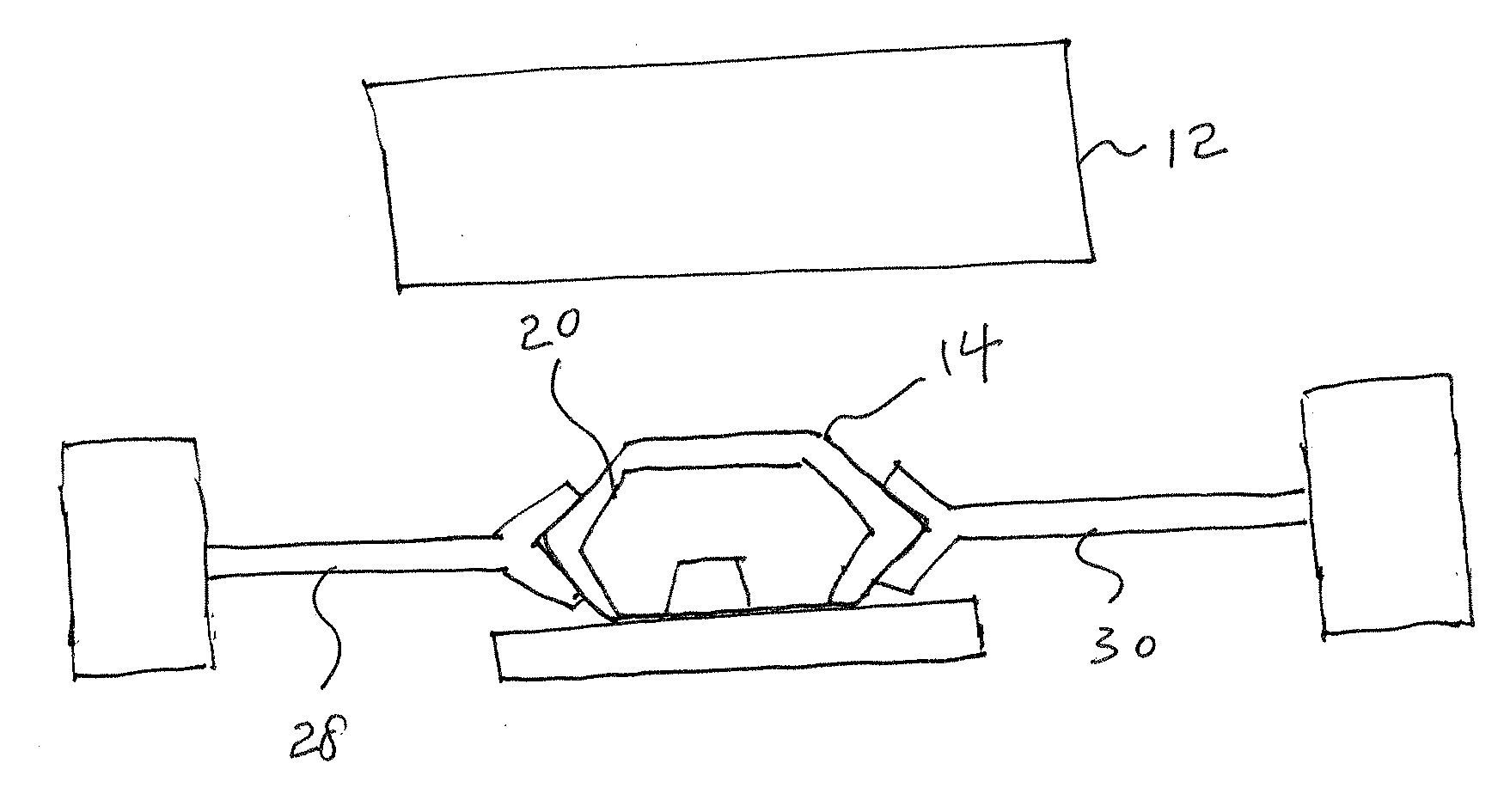

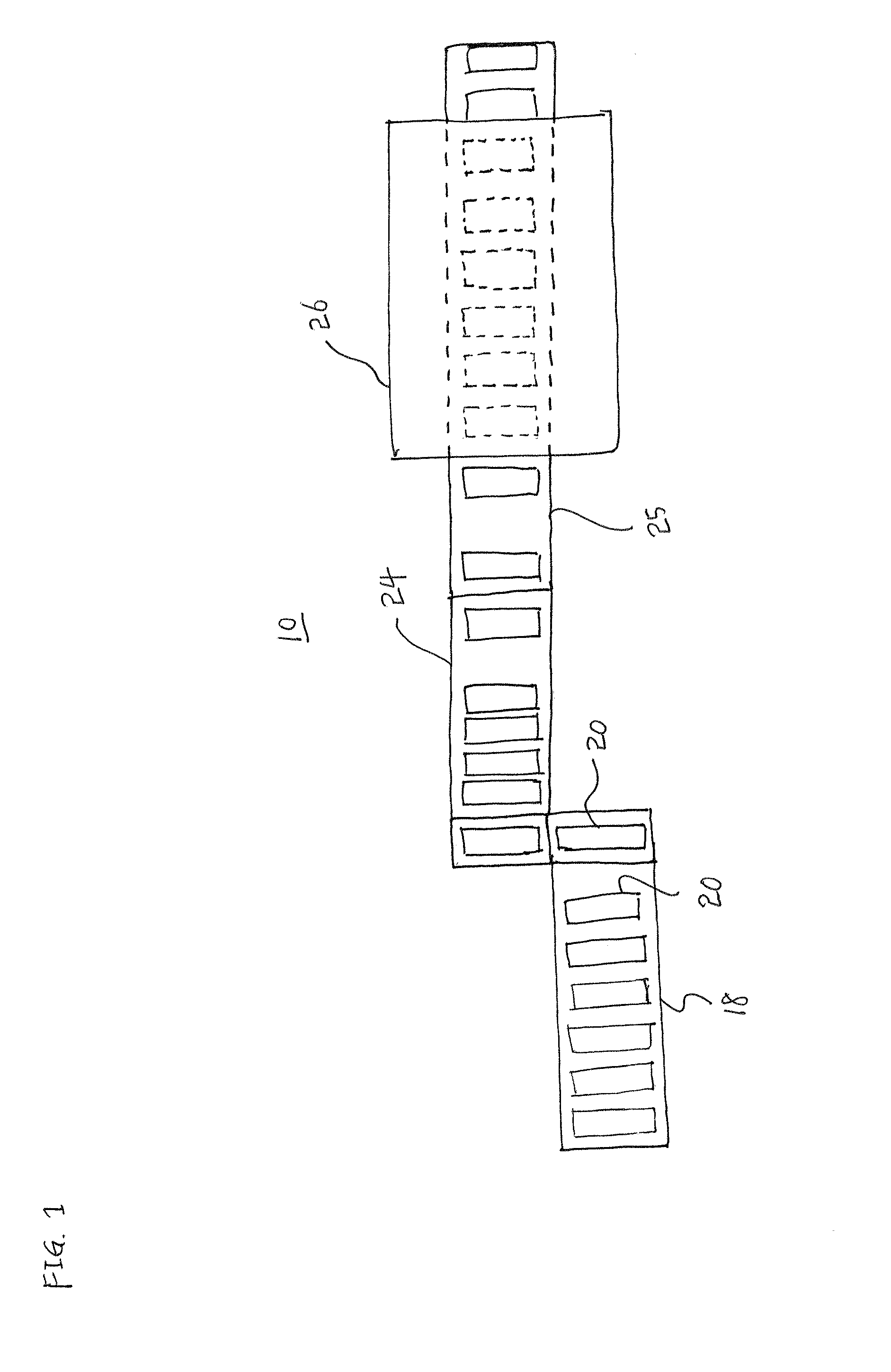

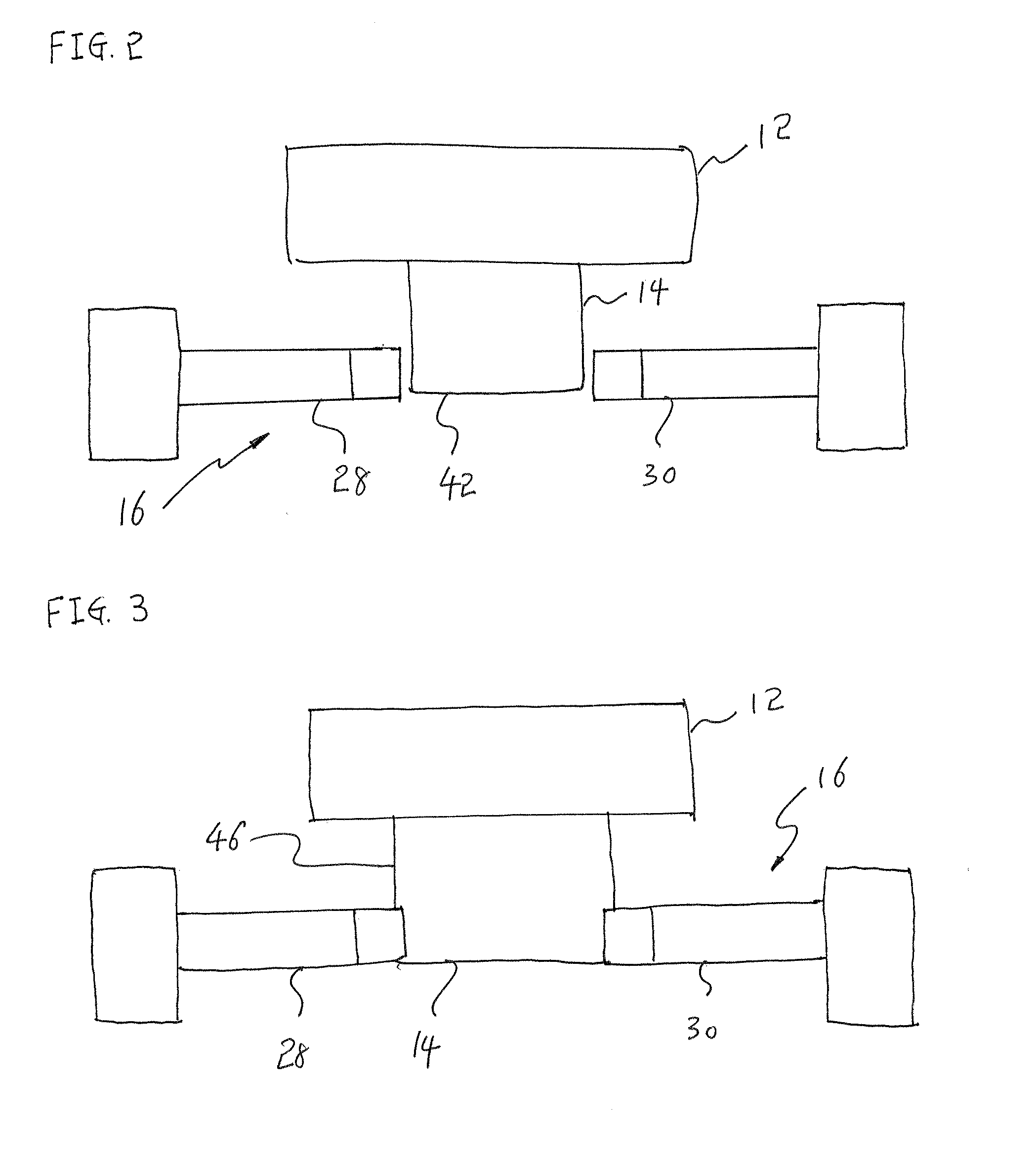

[0029]FIGS. 1 and 2 show a sleeving equipment 10 for egg package that includes a sleeve dispenser 12 that is adapted to dispense a sleeve 14 one by one, a sleeve control jig 16 that is adapted to control the sleeve 14 that is dispensed by the sleeve dispenser 12, a first egg package conveying device 18 that is adapted to convey one or more egg packages 20 before the sleeve 14 is positioned around the egg package 20, an egg package inserter 22 (refer to FIG. 6) that is adapted to insert the egg package 20 into the sleeve 14, a second egg package conveying device 24 that is adapted to convey the egg package 20 and the sleeve 14 placed around the egg package 20 after the sleeve 14 is positioned around the egg package 20, a heat tunnel 26 that is adapted to heat shrink the sleeve 14 whereby the sleeve 14 is fixed to the egg package 20, and a third egg package conveying device 25 that is adapted to move the egg package with the sleeve through the heat tunnel 26.

[0030]The egg packages 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com