Pipe clip

a technology of pipe clips and clips, applied in the field of pipe clips, can solve the problems of reducing the fitting time and often attaching pipes under difficult circumstances, and achieve the effect of facilitating movement, effective tightening of the clip around the pipe, and convenient closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

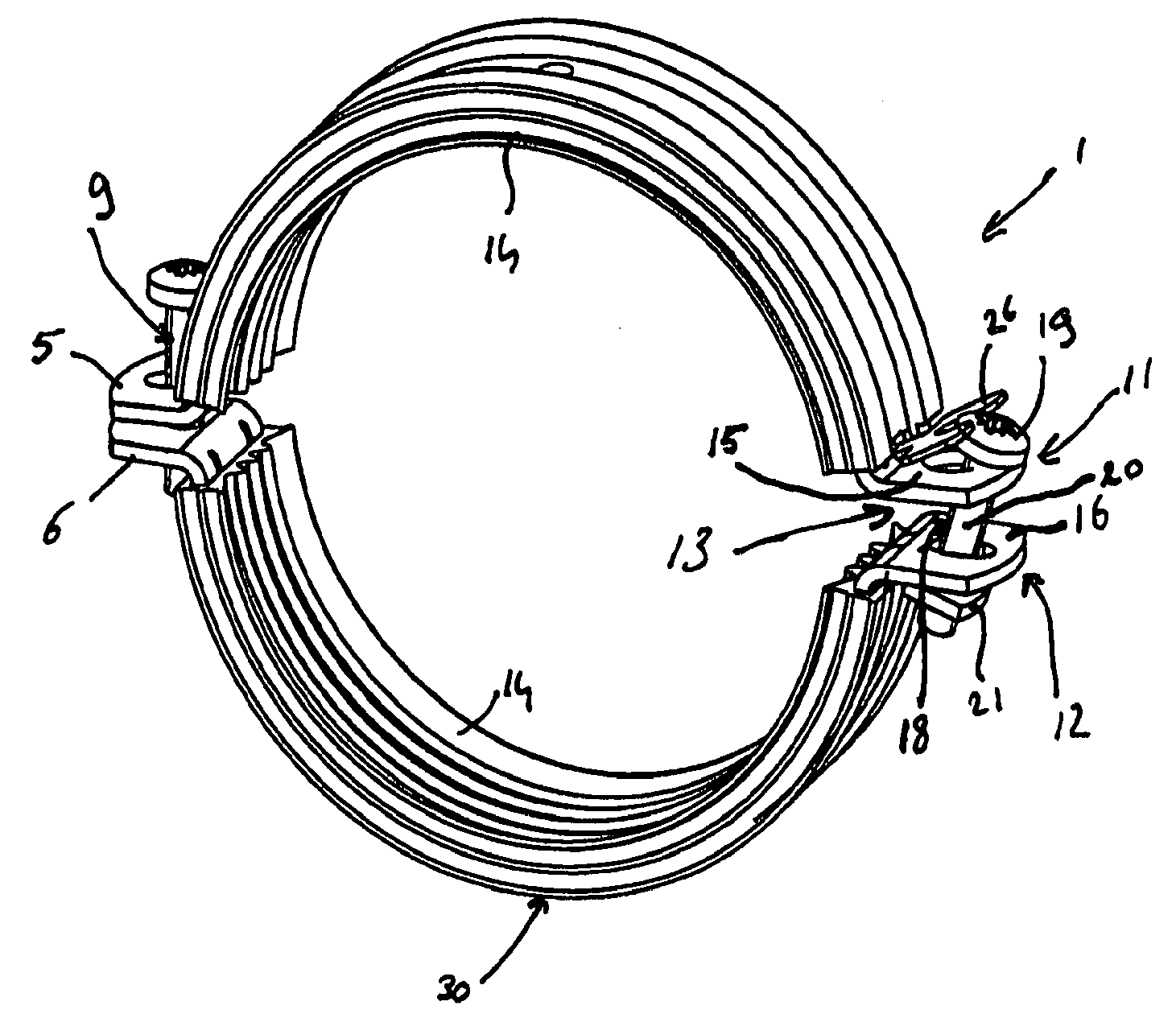

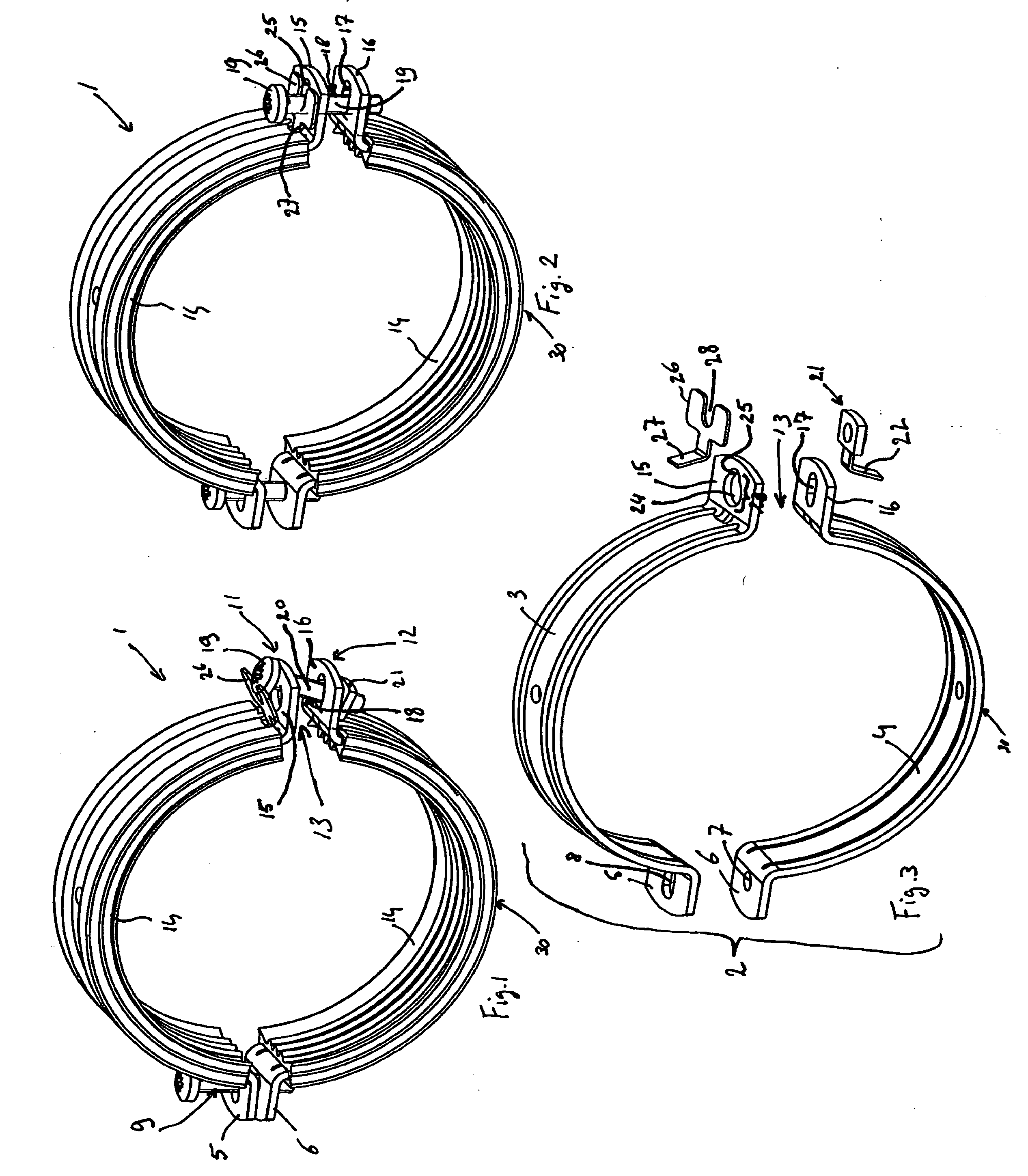

[0014]FIGS. 1-3 show a pipe clip 1 with a metal clip body 2 comprising two metal clip halves 3 and 4 respectively. The clip halves 3 and 4 are provided at one end with flanges 5 and 6 respectively. The flange 6 is provided with a hole 7 which is provided with a screw thread and into which a tightening screw 9 can be screwed. The flange 5 is provided with an elongate hole 8 through which the shank of the tightening screw 9 can be inserted. The elongate shape of the hole 8 allows the clip half 3 to be moved in a hinging manner in relation to the other clip half 4 around a hinge axis which is substantially parallel to the axial direction of the clip 1, when the tightening screw 9 has not been fully tightened. Per se, the hole 8 could also be shaped differently, provided that a hinging movement between the clip halves is possible. Per se, the clip halves 3, 4, could also be connected by means of other hinging means.

[0015]The clip body 2 has a first end 11 and a second end 12 which delim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com