Method for analyzing fluid flow within a three-dimensional object

a three-dimensional object and fluid flow technology, applied in the field of three-dimensional object analysis, can solve the problems of high level of skill and judgment, laborious and error-prone task, complex task that can only realistically be performed using computer models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

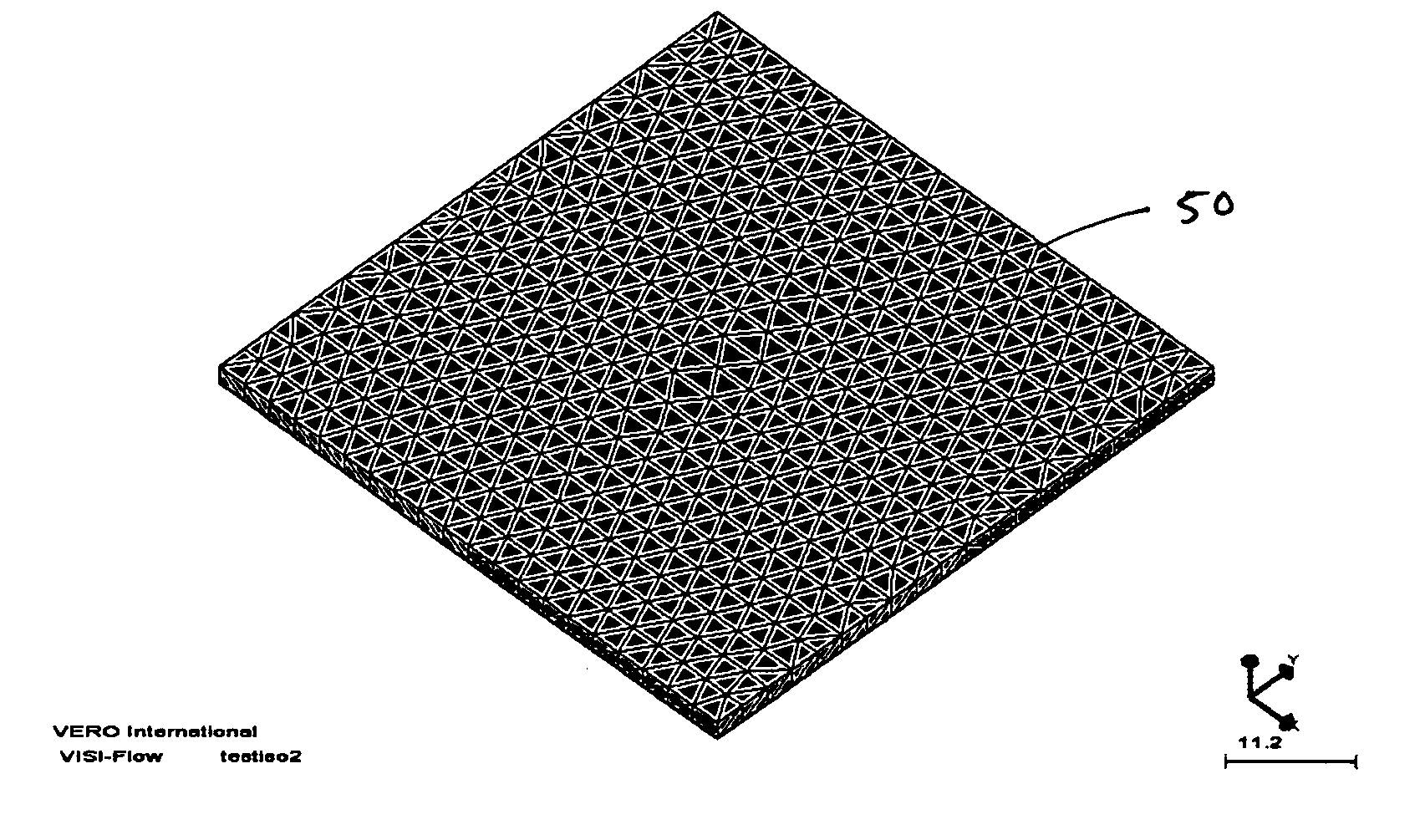

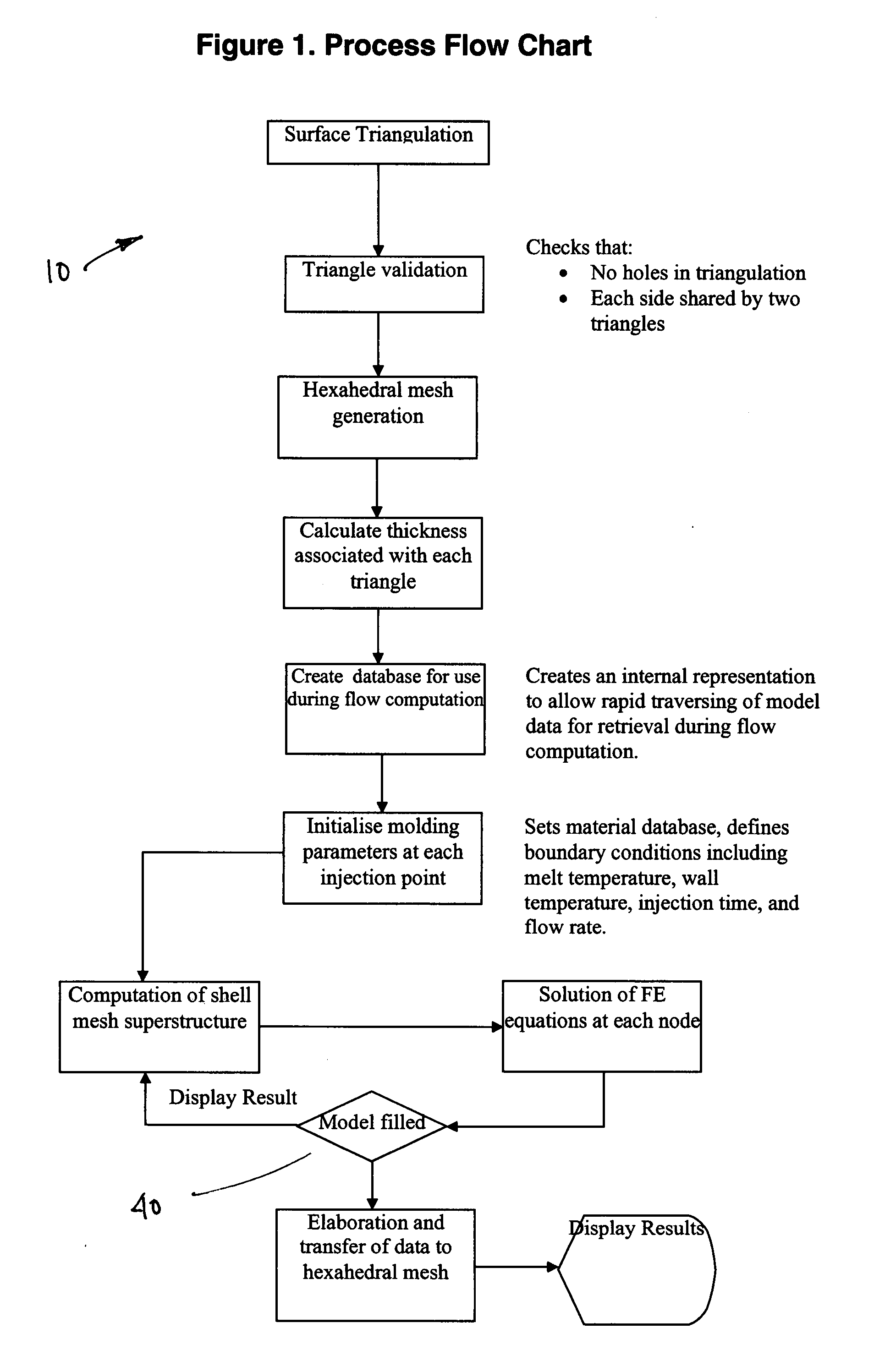

[0058]Referring to the drawings and, in particular, to FIG. 1 thereof, the flow analysis system of the present invention is provided and is referred to generally by reference numeral 10. The system 10 combines aspects of the mid-plane generation and prismatic filling systems in a way that is transparent to the user.

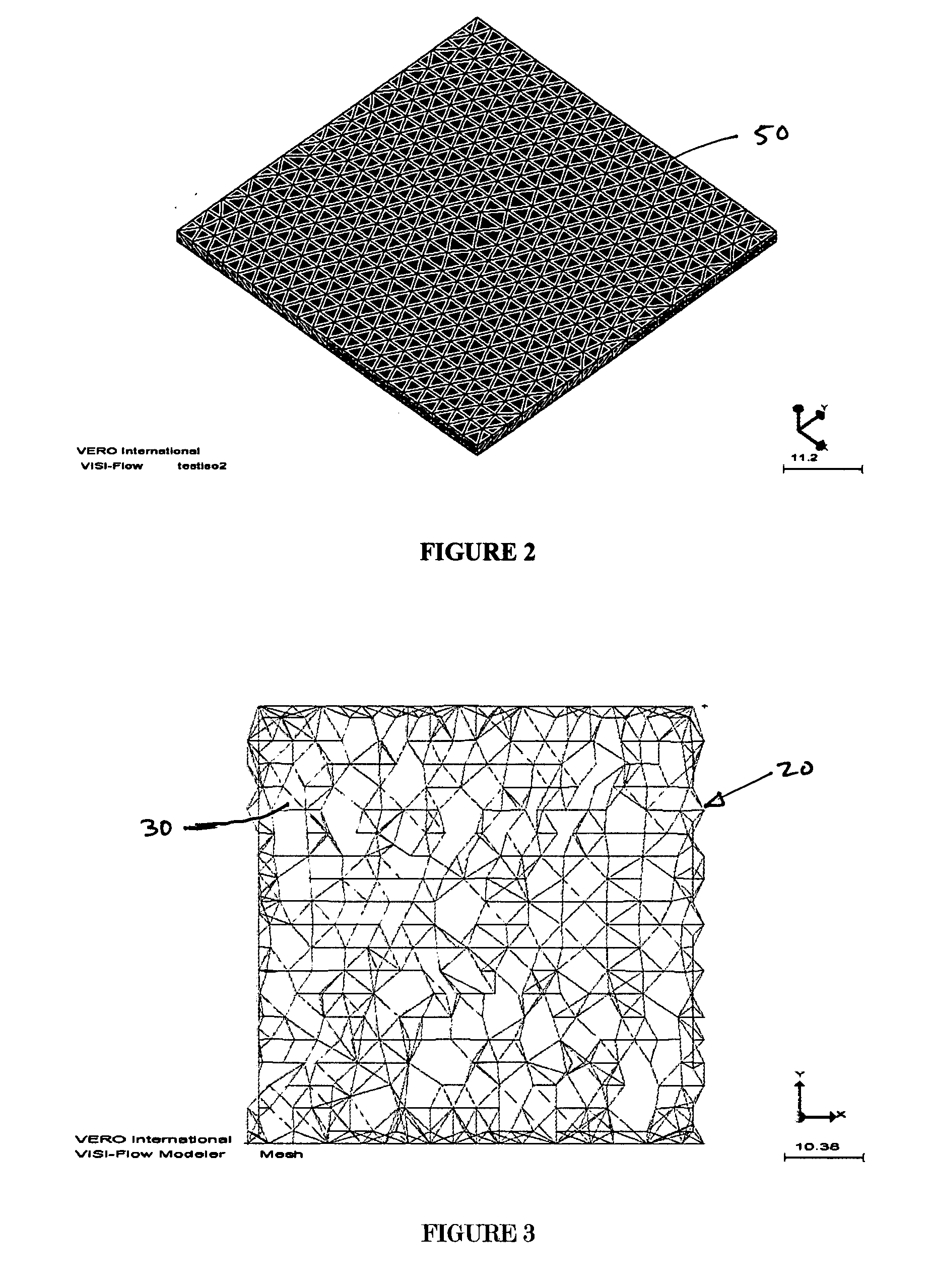

[0059]The system 10 of the present invention calculates the mid-plane mesh or shell mesh of a three-dimensional object in two stages. The first stage is to triangulate the faces of the solid model. FIG. 3 illustrates such a triangulated structure 20. It should be noted that the triangles 30 are very varied in size and shape. Some will be isosceles, some equilateral, and others will be long and thin. The triangle shapes depends upon the geometry of the part, and each triangle has an associated thickness.

[0060]The system 10 uses this triangulated structure to construct a solid mesh 40 that is used when the analysis is complete to provide feedback on the flow at cross sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com