Continuous electrolytic refining device for metal uranium

a technology of electrolysis refining and metal uranium, which is applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of large quantity of products which cannot be obtained continuously, tissue which is difficult to detach, and inability to achieve continuous operation, etc., to achieve high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Hereinafter, embodiments of a continuous electrolytic refining device according to the present invention will be described in detail with reference to the attached drawings for those having ordinary skill in the arts to which the present invention belongs to easily execute. However, the present invention may be realized in various different shapes and is not limited to the embodiments described herein.

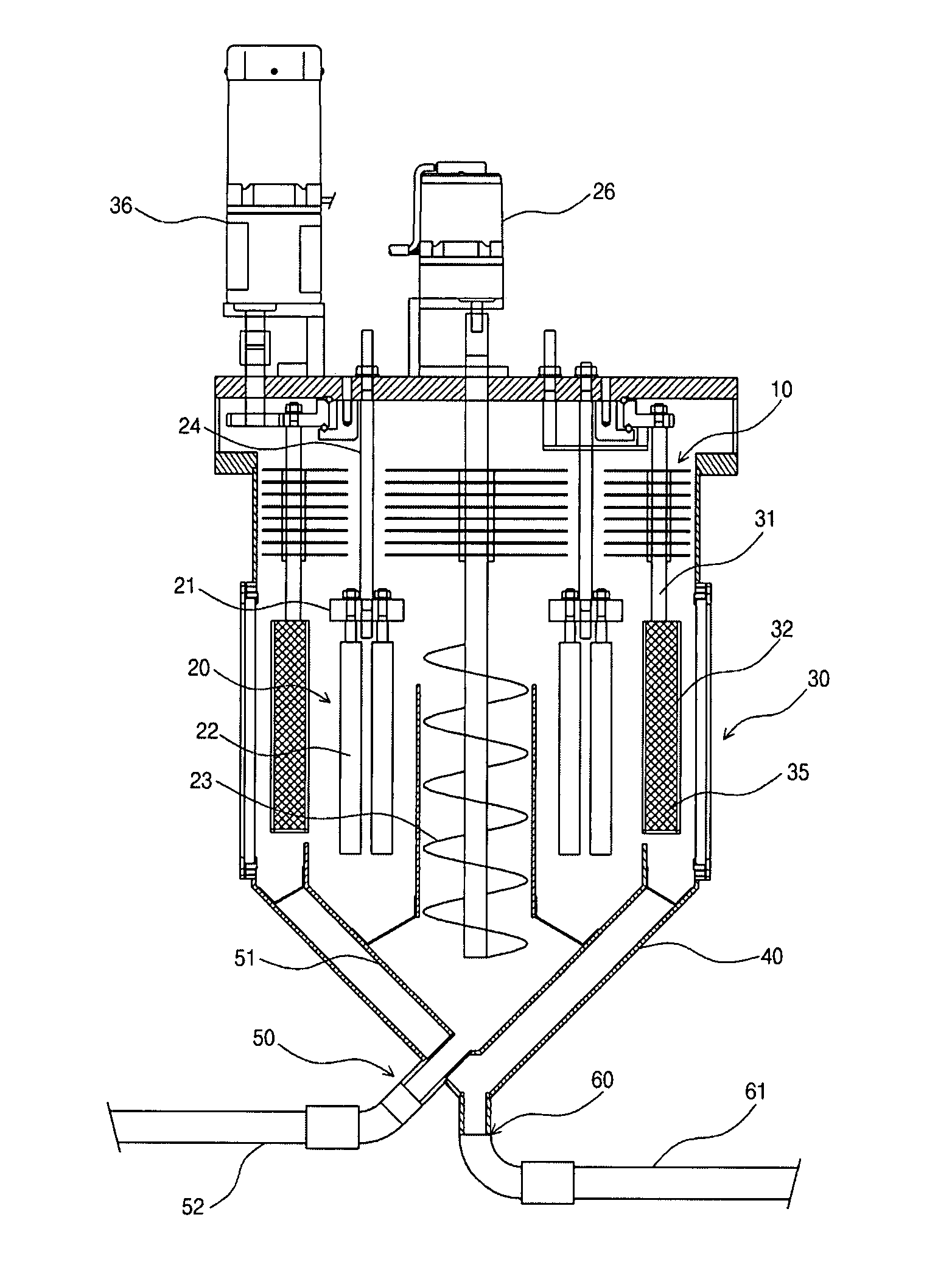

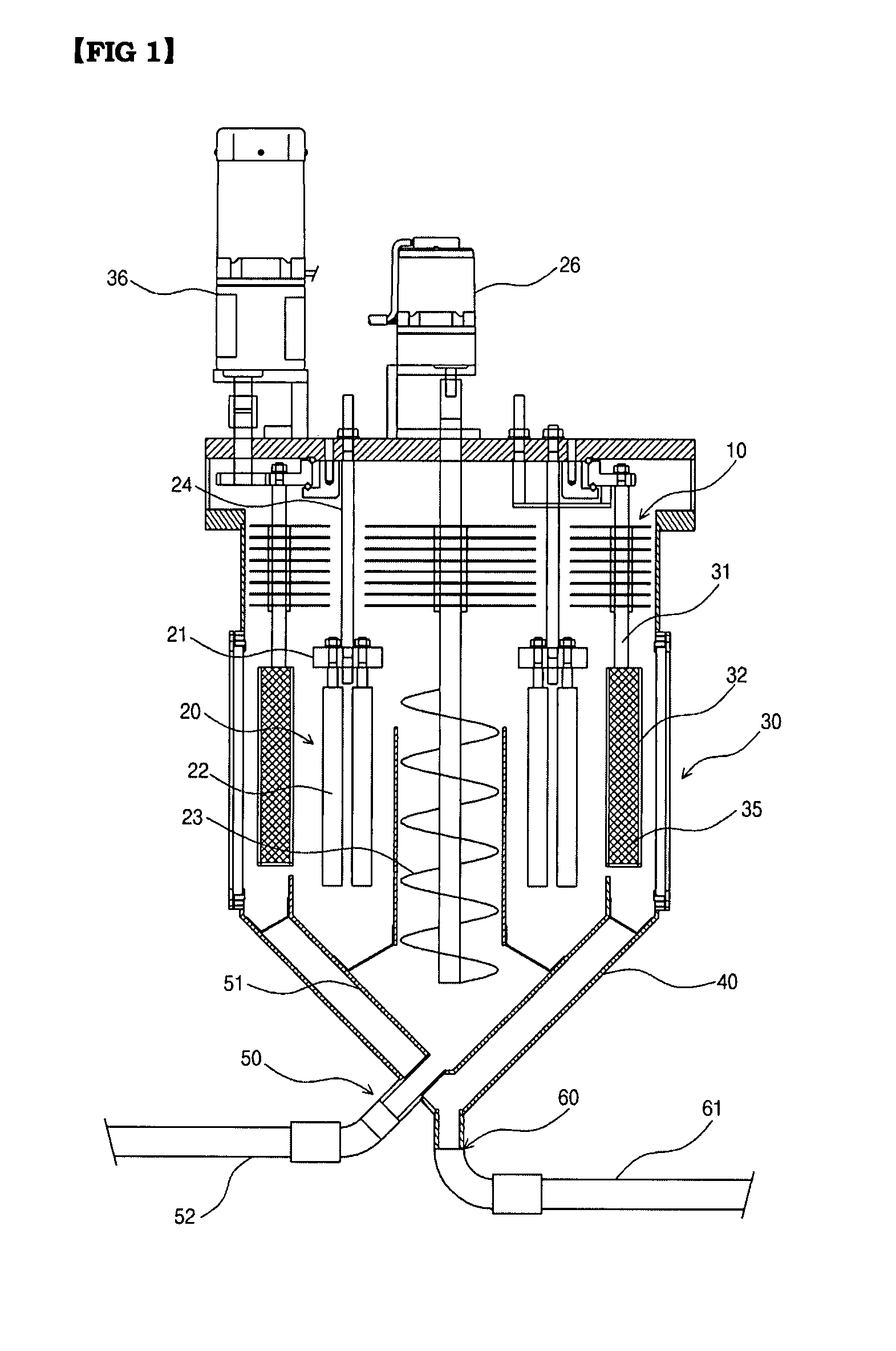

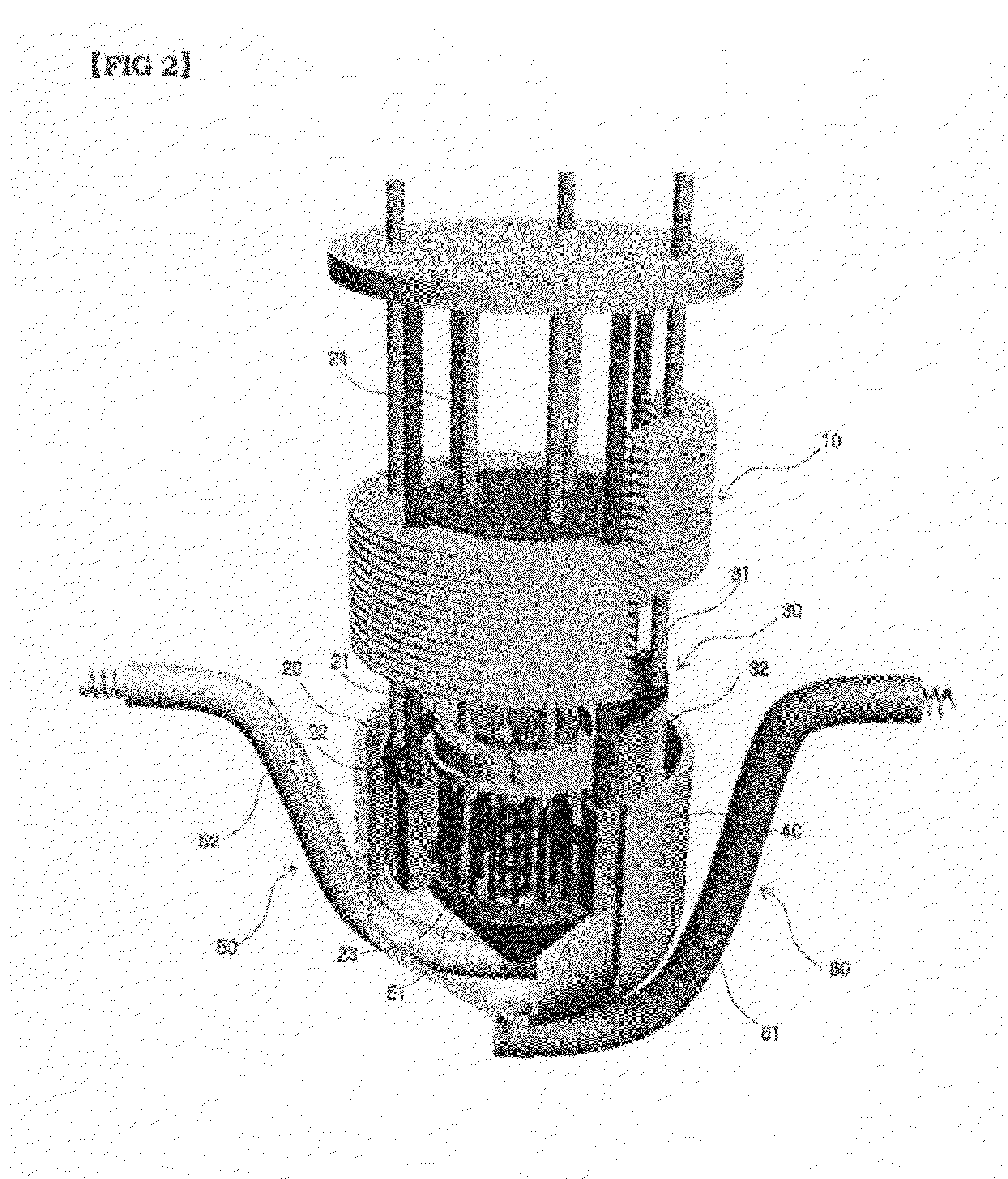

[0041]FIG. 1 is a cross-sectional view showing a continuous electrolytic refining device of metal uranium in accordance with an embodiment of the present invention, and FIG. 2 is a partial cut-off perspective view stereographically showing the continuous electrolytic refining device of metal uranium shown in FIG. 1.

[0042]Referring to FIGS. 1 and 2, the continuous electrolytic refining device for metal uranium in accordance with the present embodiment comprises a cathode section (20) fixed to the lower side of a heat radiation plate (10), an anode section (30) receiving the used n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Mesh size | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com