Lock for shelving assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

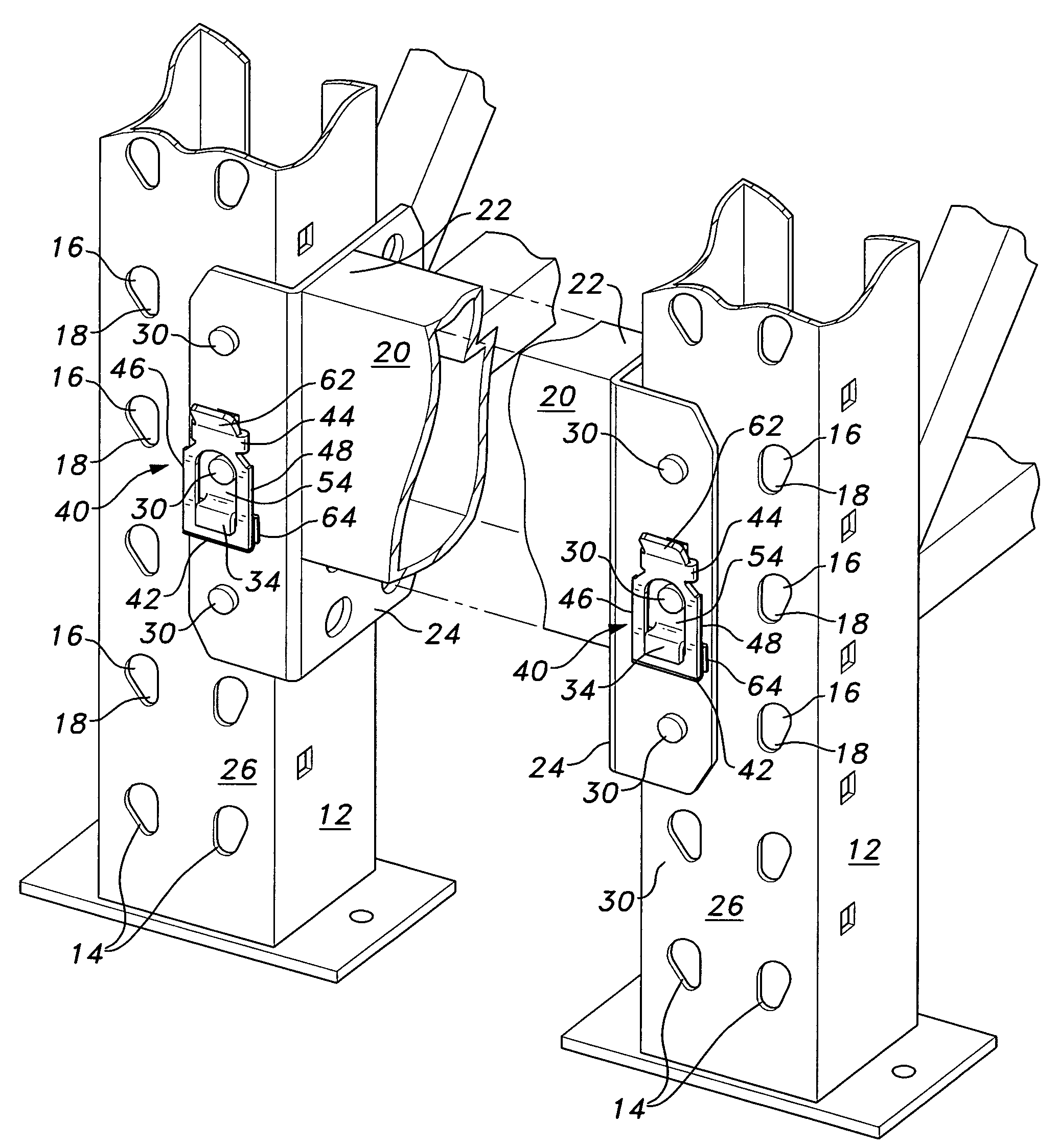

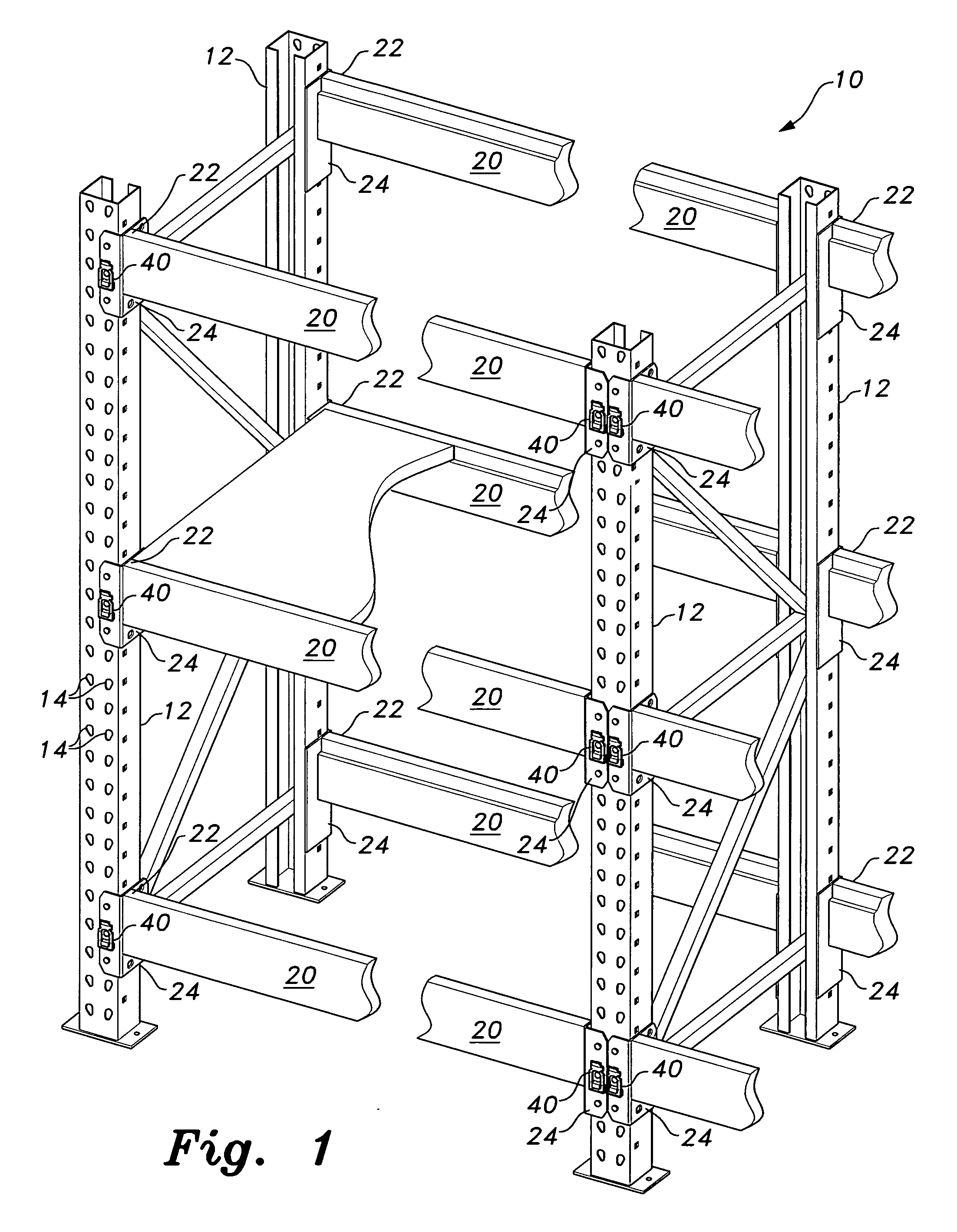

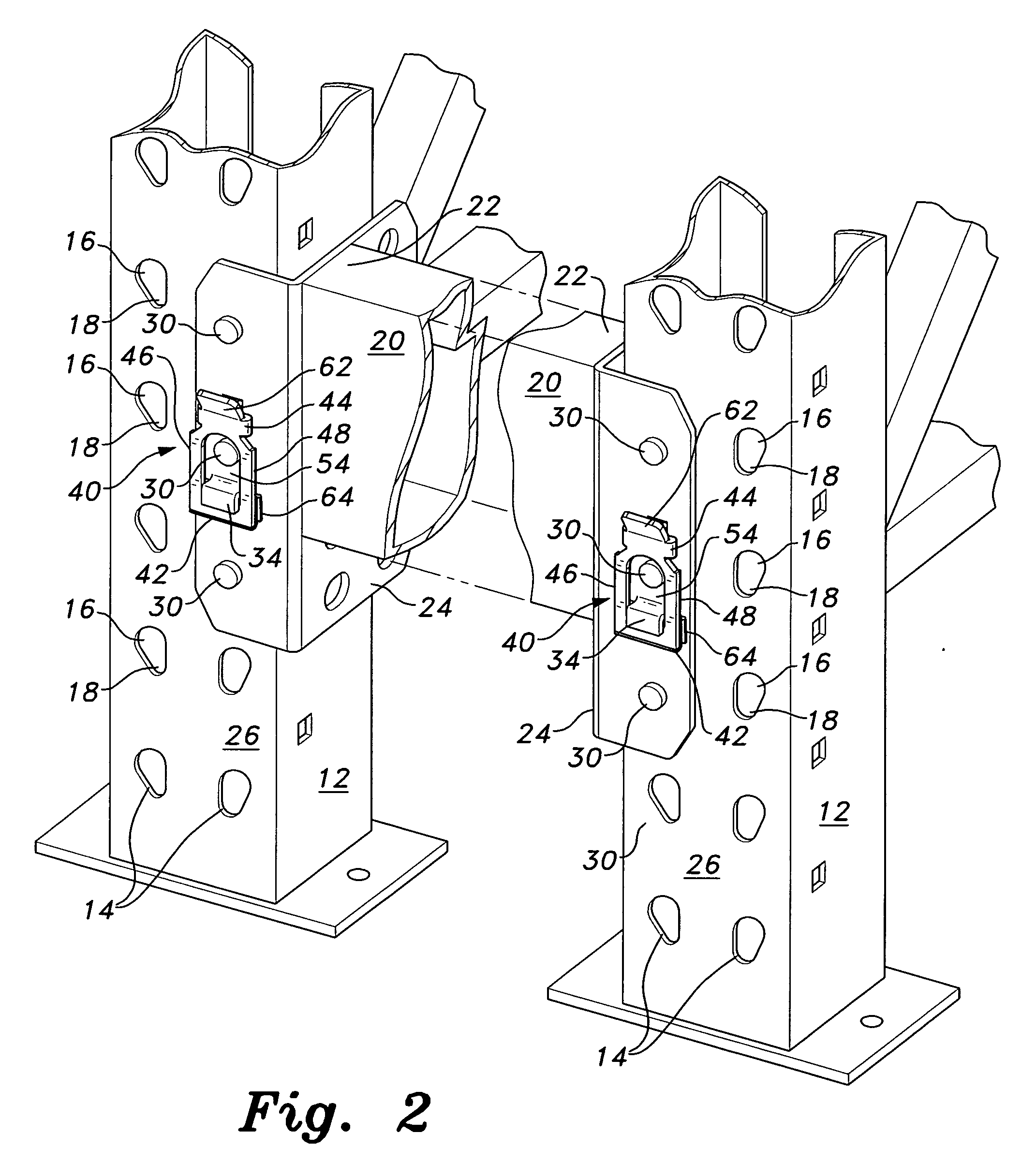

[0020]The present invention relates to various embodiments of a lock for a shelving assembly, assuring that the horizontal crossmembers or shelf support members cannot be lifted from their attachment to the standards or uprights of the assembly. FIG. 1 of the drawings provides an illustration of an exemplary shelving assembly 10, including a plurality of uprights 12 with horizontal crossmembers 20 secured between the uprights 12 and supporting one or more shelves thereon. The detail perspective view of FIG. 2 illustrates further details of this structure, showing the elongated connector pin passages 14 formed through each of the uprights 12.

[0021]Each of the connector pin passages 14 includes a relatively wider upper portion 16 dimensioned to allow the passage therethrough of the relatively wider head of the connector pin, and a relatively narrower lower portion 18 supporting the narrower shank of the pin therein and capturing the wider head of the pin therebehind. Each of the conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap