Lubrication System and Internal Combustion Engine Comprising Such a System

a technology of lubrication system and internal combustion engine, which is applied in the direction of pressure lubrication, machines/engines, mechanical equipment, etc., can solve the problems of complex system, high cost, and waste of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

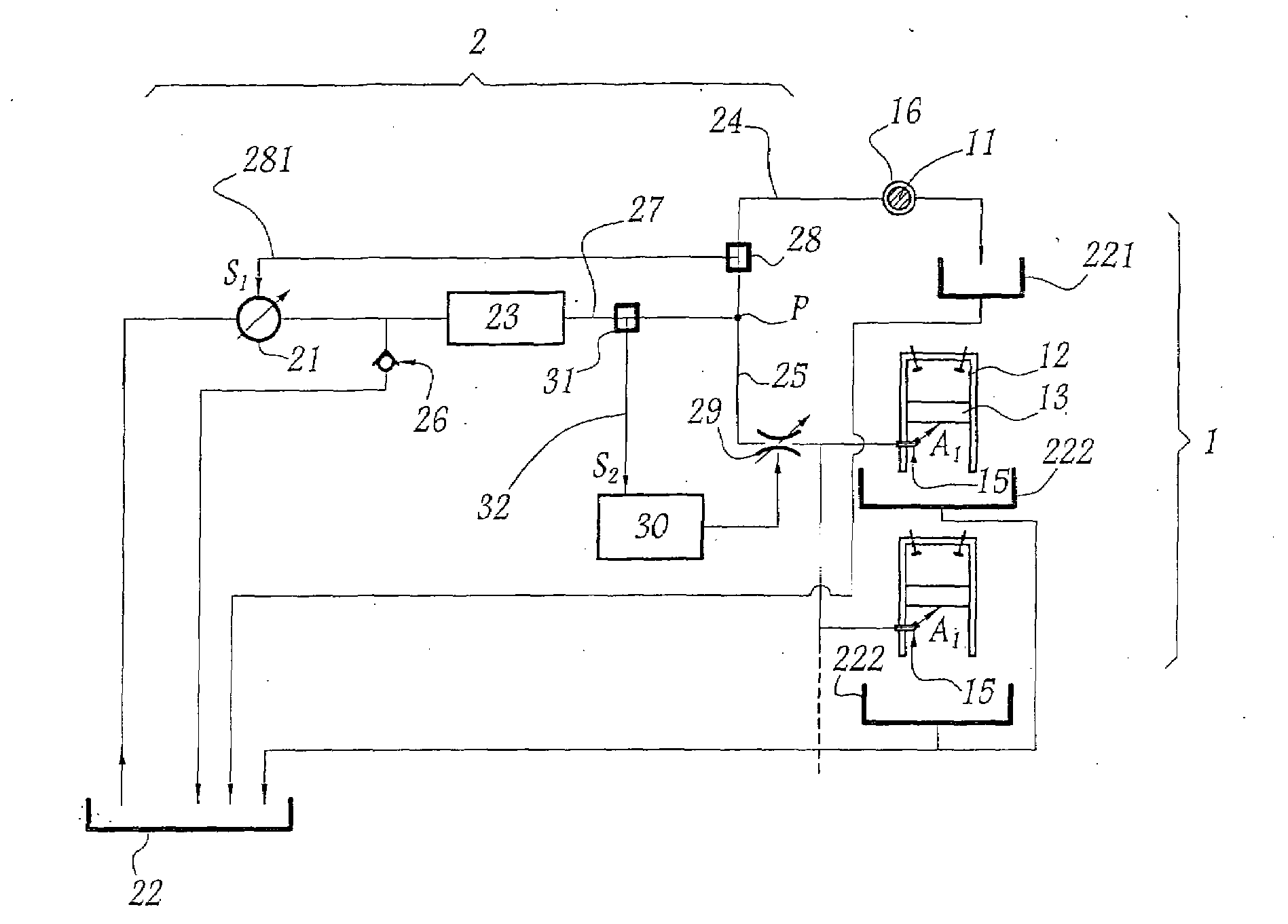

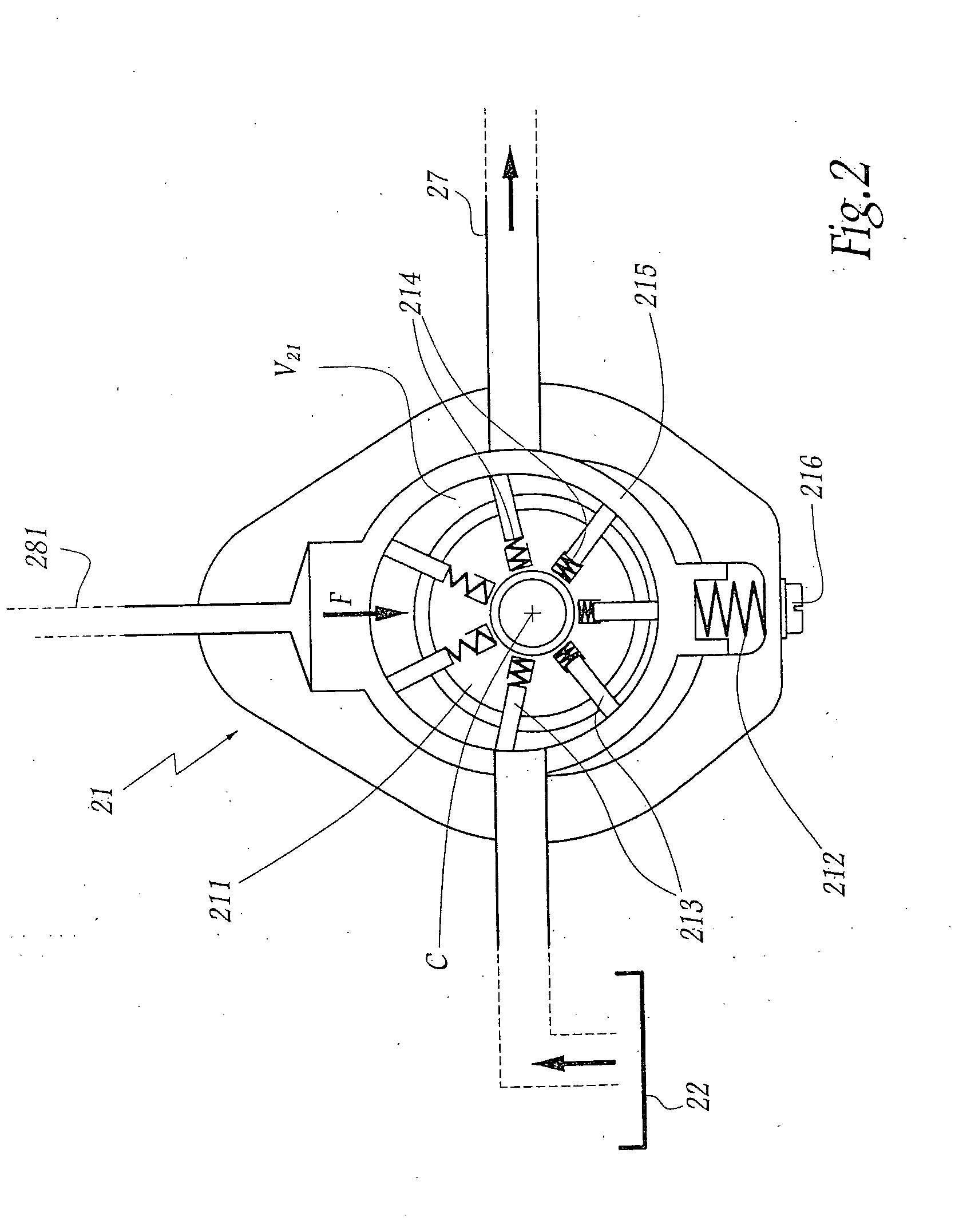

[0022]The lubrication system represented on FIG. 1 is adapted to be mounted onto an internal combustion engine 1 which comprises a crank shaft 11 and several cylinders 12, only two cylinders being represented. A piston 13 is slidably movable within each cylinder 12, between a top dead center position and a bottom dead center position represented on FIG. 1. A piston cooling jet 15 is provided for each cylinder 12 and is adapted to direct a flow of oil towards its piston 13 in its bottom dead center position, as represented by arrows Ai on FIG. 1.

[0023]Crank shaft 11 is supported by several bearings 16. Only one bearing is represented on FIG. 1. Oil is to be fed to each interface between a bearing 16 and crank shaft 11.

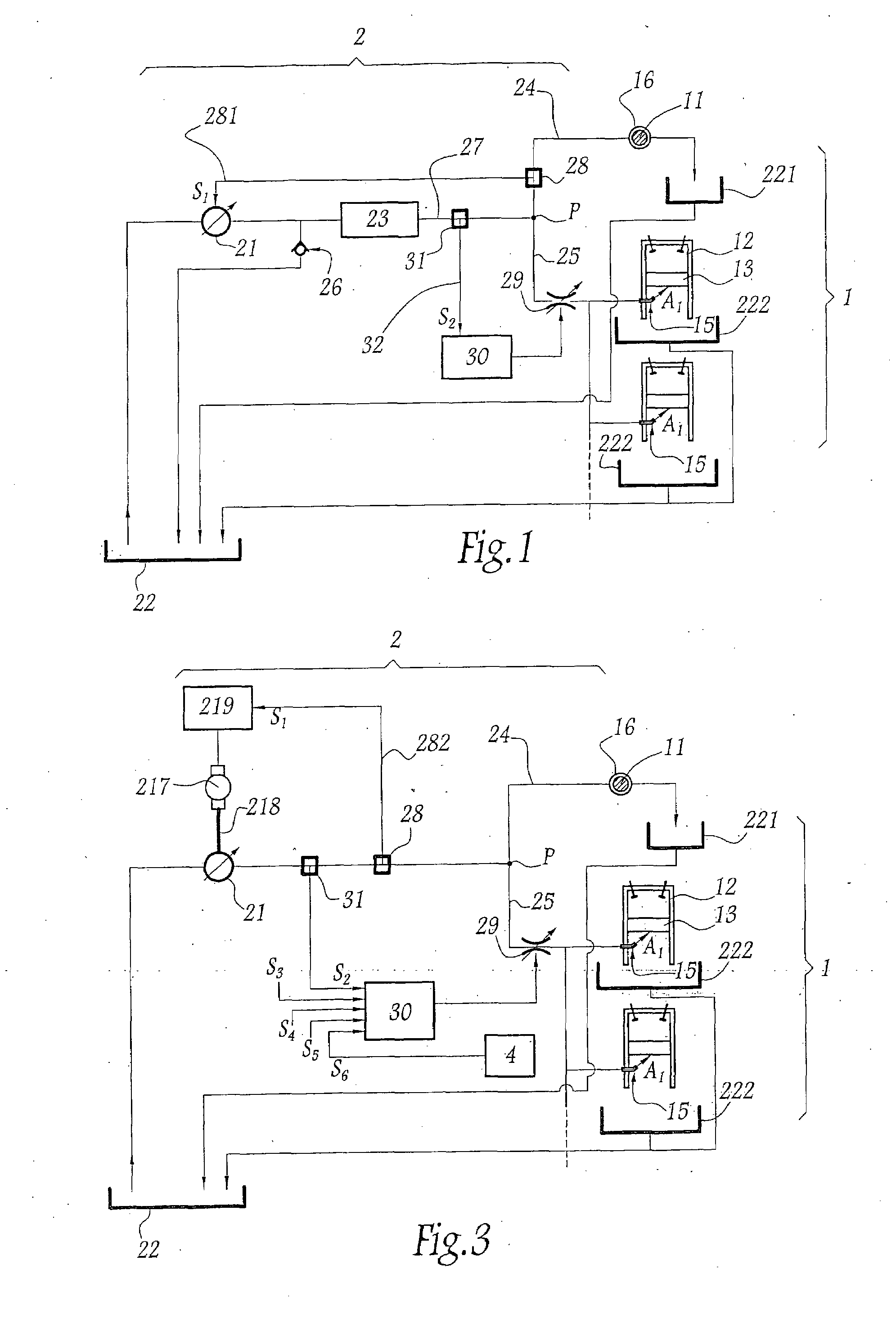

[0024]To this purpose, a lubrication system 2 includes a vane pump 21 adapted to suck oil from a sump and to feed a heat exchanger 23 which, itself, feeds two lines, namely a first line 24 feeding the interface between crank shaft 11 and at least one bearing 16 and a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com