Temperature control device

a temperature control device and temperature technology, applied in the direction of temperature control using electric means, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of inability to quickly change the temperature inside the temperature adjustment unit is not easy to change, etc., to achieve the effect of reducing the amount of work and quick placemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0054]A first embodiment of the temperature control device according to the present invention will be described below with reference to the drawings.

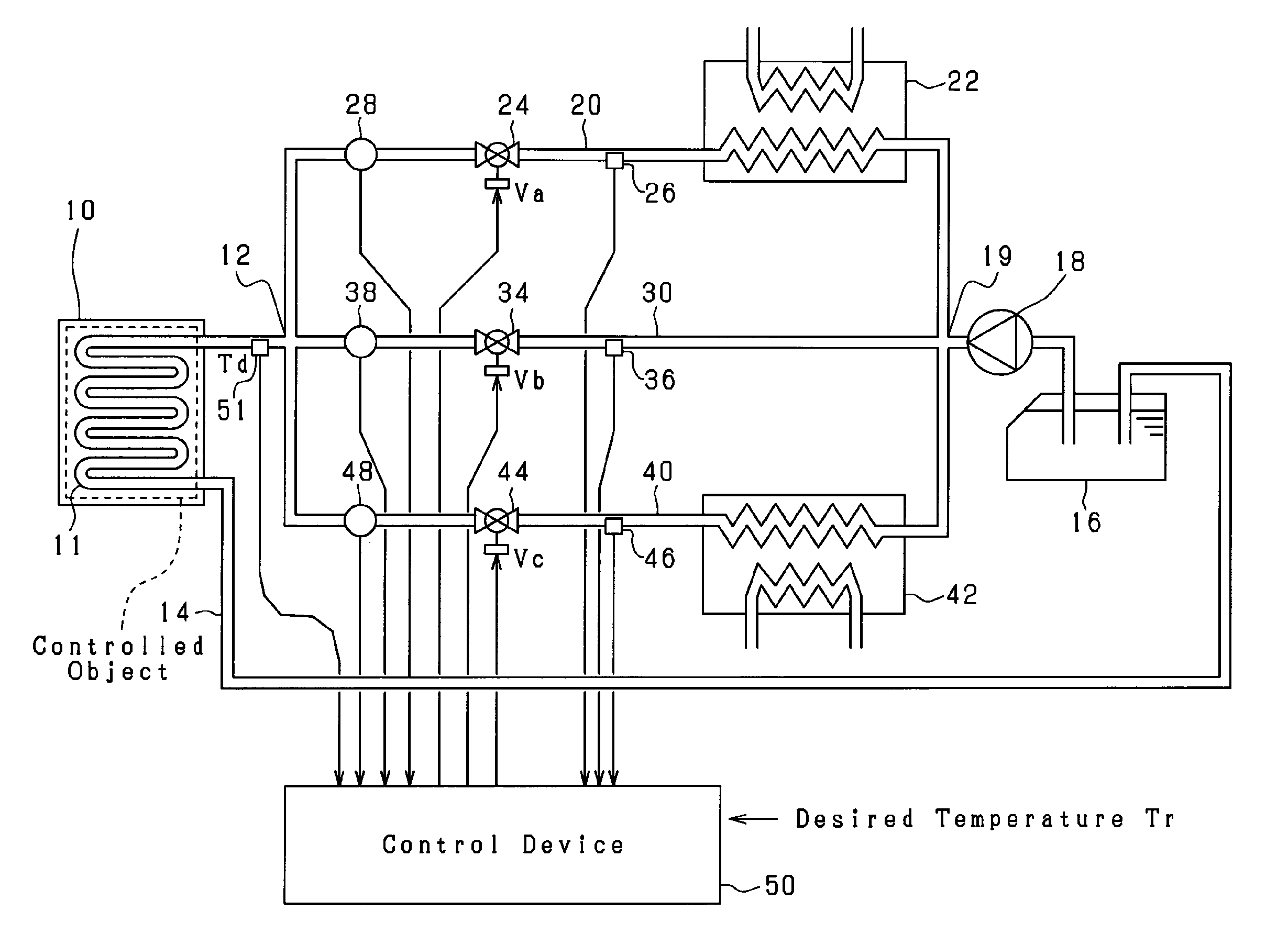

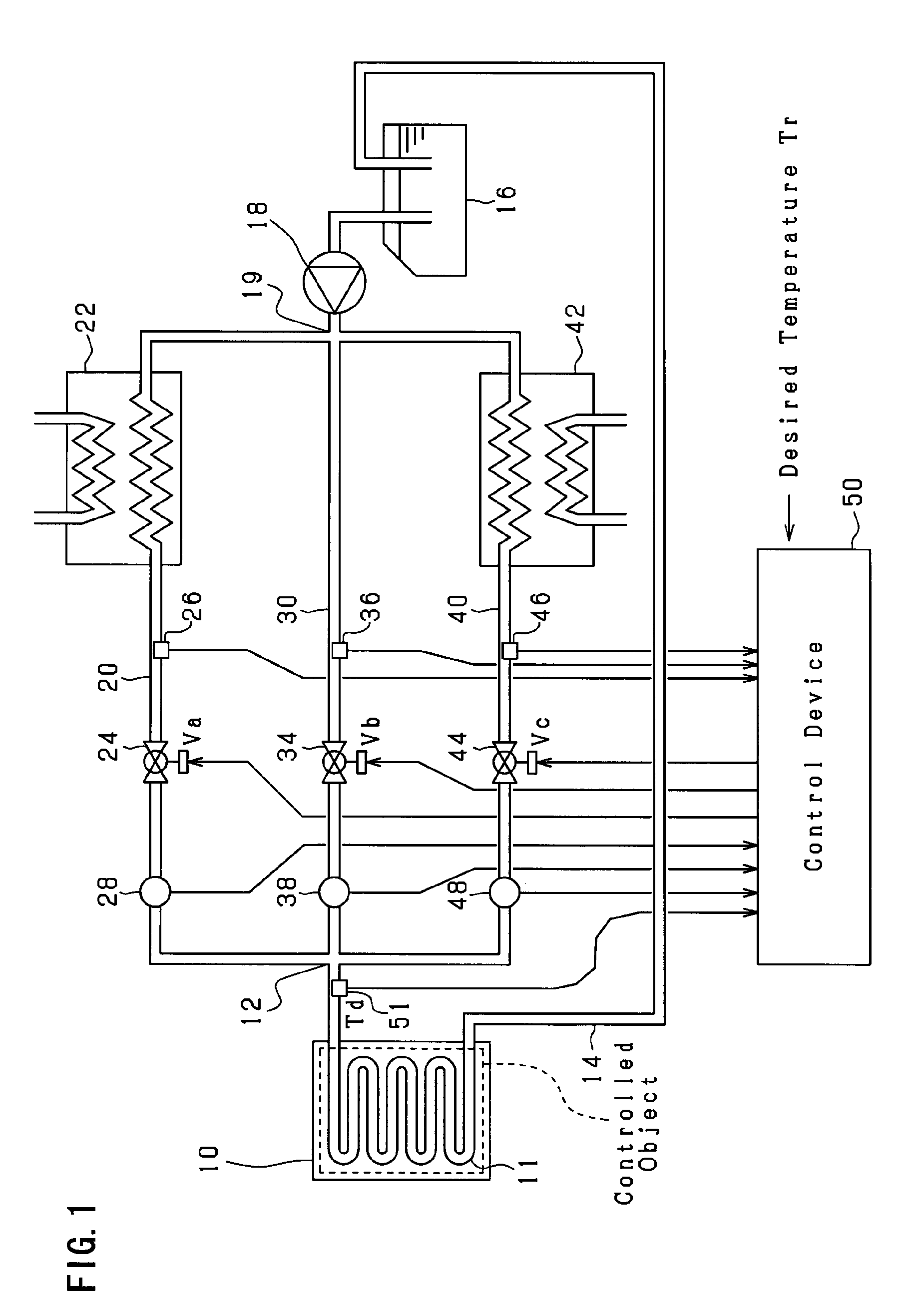

[0055]FIG. 1 shows the overall construction of the temperature control device according to the present embodiment.

[0056]The illustrated temperature control device is employed in, for example, processes / manufacturing steps in the bioengineering field and the chemical engineering field, bioengineering / chemical experimentation, semiconductor manufacturing processes, manufacturing processes for precision machinery. The temperature control device comprises a temperature adjustment plate 10. The temperature adjustment plate 10 is a plate shaped member that is capable of supporting a controlled object from below by mounting the controlled object on top thereof, and exchanges heat energy with the controlled object. More specifically, a pathway (temperature adjustment unit 11) is provided in the interior of the temperature adjustment plate 10, a...

second embodiment

[0109]A second embodiment will be described below with reference to the drawings that are focused on the points that differ from the first embodiment.

[0110]FIG. 8 shows the overall construction of the temperature control device according to the present embodiment. As shown in FIG. 8, in the present embodiment, a effusion pathway 60 that effuses the fluid inside the cooling pathway 20 to the discharge pathway 14 is connected between the cooling temperature sensor 26 and the cooling valve 24 along the cooling pathway 20. In addition, a effusion pathway 62 that effuses the fluid inside the heating pathway 40 to the discharge pathway 14 is connected between the heating temperature sensor 46 and the heating valve 44 along the heating pathway 40.

[0111]These effusion pathways 60 and 62 are sufficiently smaller than the path dimensions of either of the cooling pathway 20 and the heating pathway 40. This is in order to allow a minute amount of fluid to be effused from the cooling pathway 20 ...

third embodiment

[0116]A third embodiment will be described below with reference to the drawings that are focused on the points that differ from the first embodiment.

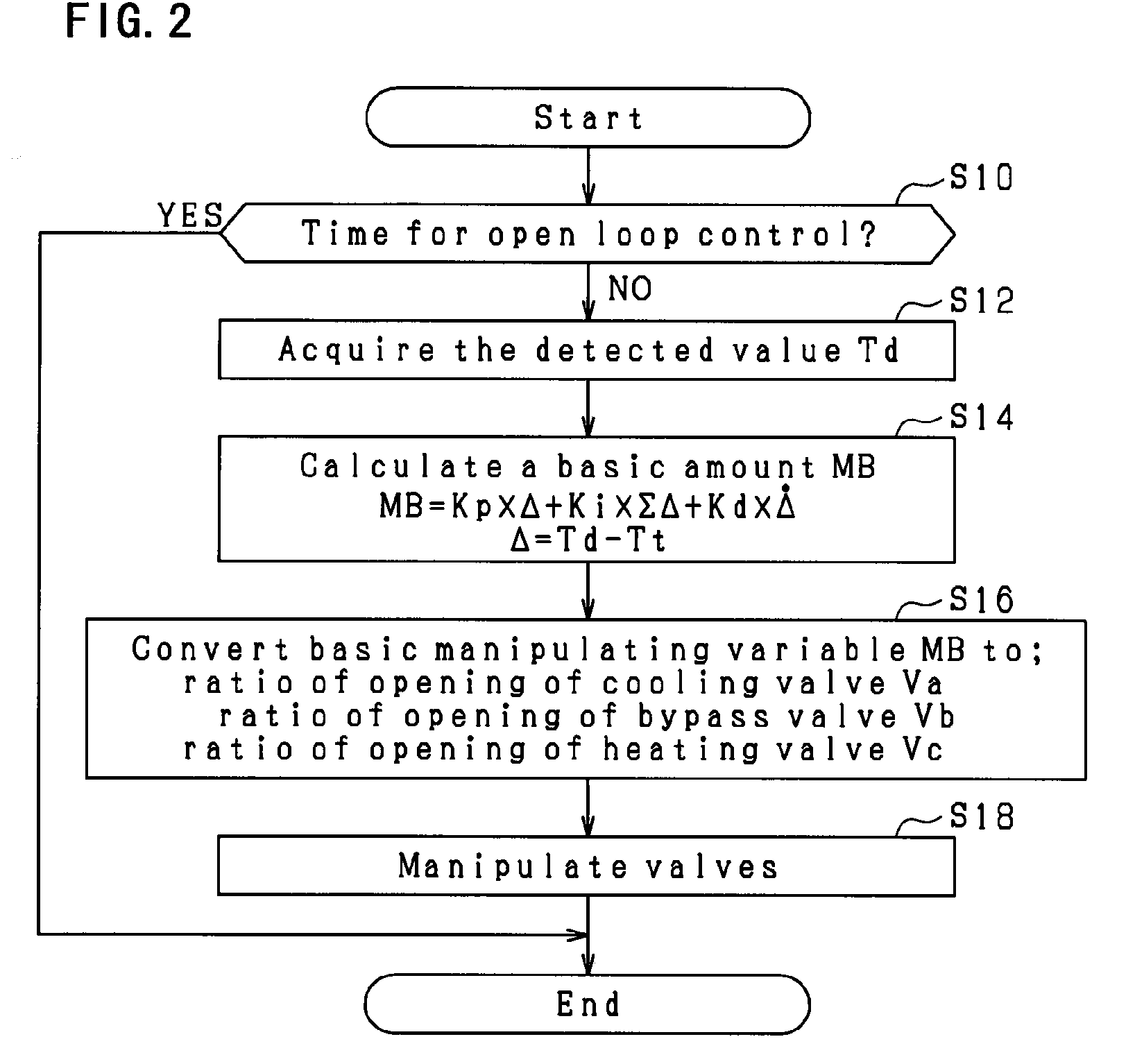

[0117]FIG. 9 shows the relationship between the basic manipulating variable MB according to the present embodiment and the ratio of opening Va, Vb and Vc of the cooling valve 24, the bypass valve 34, and the heating valve 44. As shown in FIG. 9, in the present embodiment, the ratio of opening Va of the cooling valve 24 and the ratio of opening Vc of the heating valve 44 are set so as not to be in a completely closed state. In other words, the ratio of opening Va of the cooling valve 24 will monotonically decrease in accordance with an increase in the basic manipulating variable MB when the basic manipulating variable MB is less than zero, and will be at the minimum ratio (>0) when the basic manipulating variable MB is zero or more. In addition, the ratio of opening Vc of the heating valve 44 will monotonically increase in accordance wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com