Apparatus for Driving Clothes Press Irons and Clothes Press Finishing Machine Using the Same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The best mode for carrying out this invention will be described as follows.

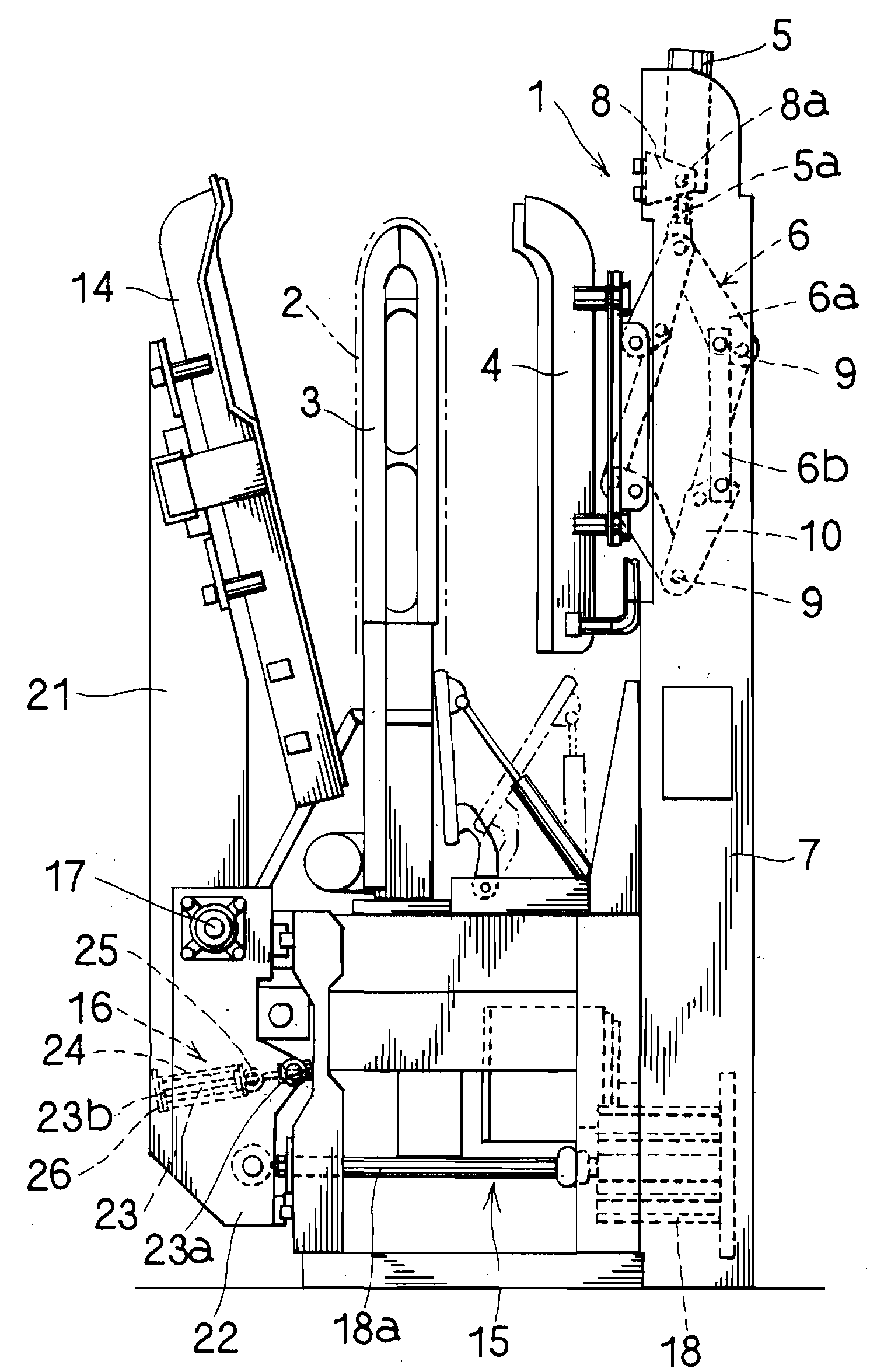

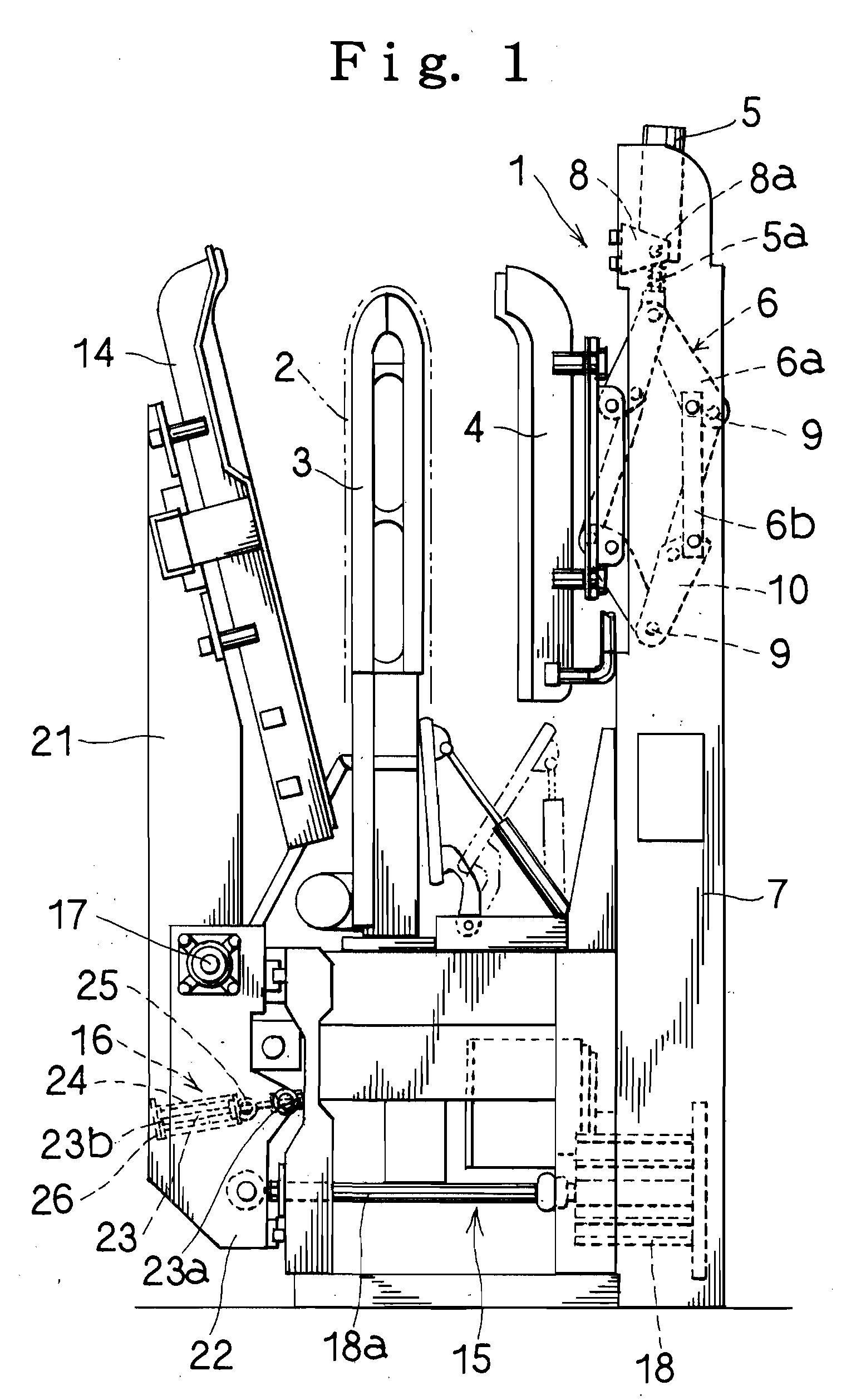

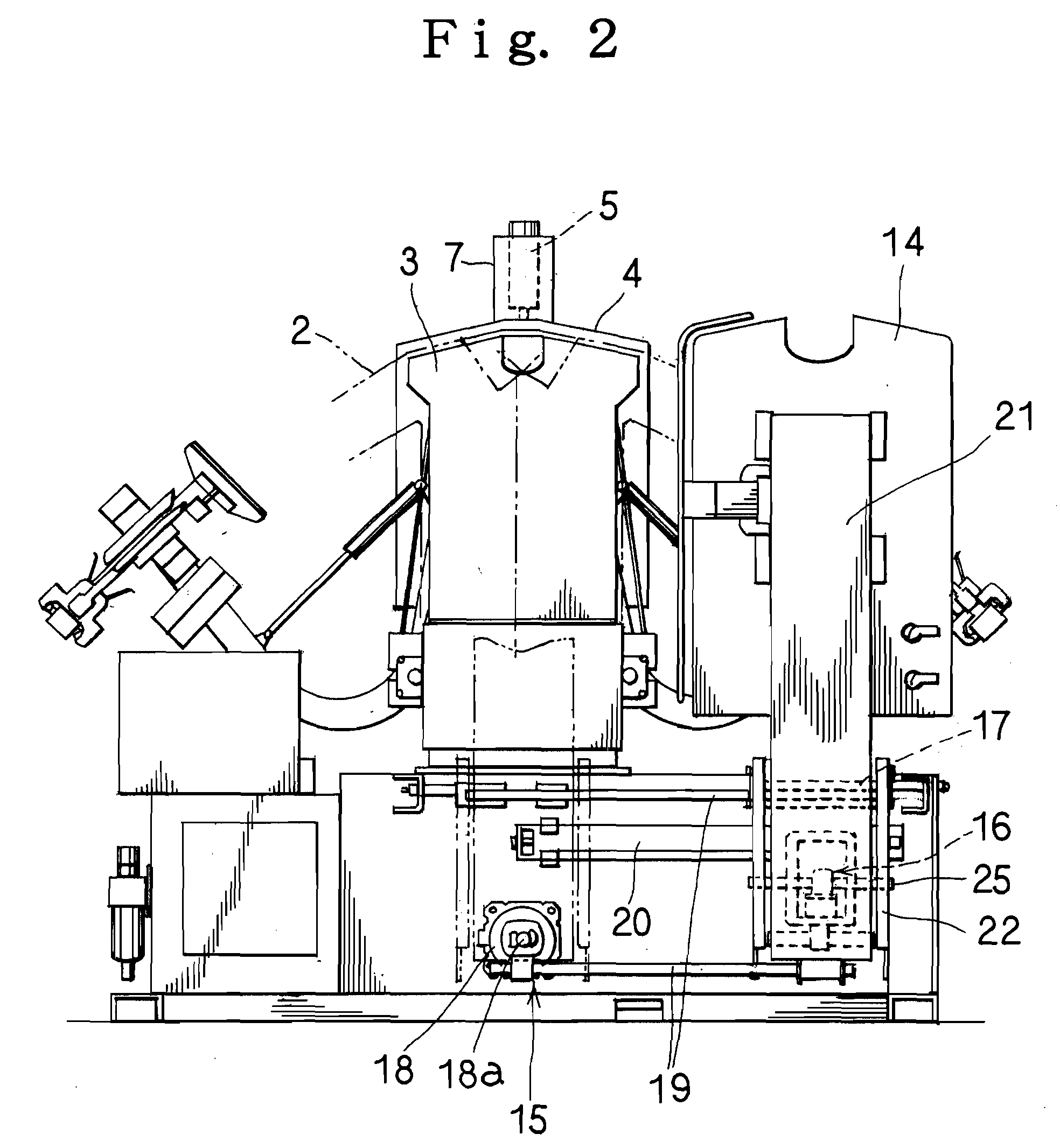

[0052]As shown in FIG. 1 and the like, the driving device 1 of this invention in its preferred embodiment is realized by a clothes press iron 4 at a rear side for pressing the rear side of a torso 3 for putting on clothes 2 and press finishing the rear surface of clothes 2.

[0053]Thus, the driving device 1 of this invention is formed by a vertical-oriented cylinder device 5 oscillating in a forward or rearward direction of a torso 3 and a cylinder device 6 fixed to the extremity end of a rod 5a of this cylinder device 5 to convert an extending or retracting operation of the rod 5a into an advancing or retracting operation of the clothes press iron 4 at the rear side.

[0054]The aforesaid cylinder device 5 is fixed in the upper part of a supporting column 7 upright just at a rear side of the torso 3 in this preferred embodiment with the rod 5a being faced downward. Reference numeral 8 denotes a fixing membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com