Automatic document feeder having document size detecting device

a document feeder and document size technology, applied in the direction of transportation and packaging, thin material processing, article separation, etc., can solve the problems of not cost-effective, complicated structure and complicated digital circuit of the document size detecting device b>20/b>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

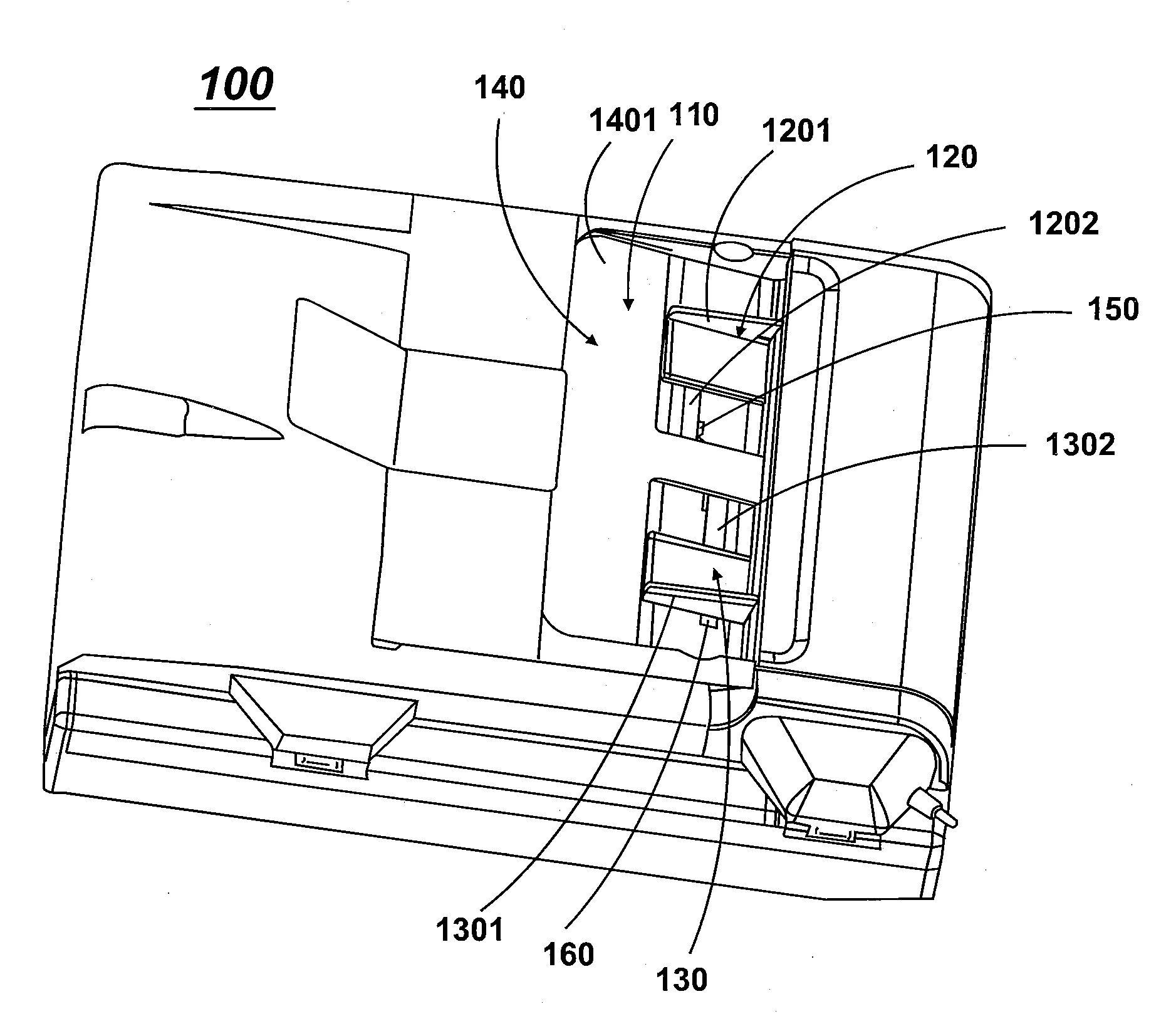

[0023]In views of the above-described disadvantages resulted from the prior art, the present invention provides an automatic document feeder having a document size detecting device. Referring to FIG. 3, a schematic perspective view of an automatic document feeder according to a preferred embodiment of the present invention is illustrated. The automatic document feeder 100 has a paper input tray 140. The paper input tray 140 has a surface 1401 for placing thereon a document (not show). In addition, a document size detecting device 110 is mounted in the paper input tray 140. The document size detecting device 110 principally includes a first paper guide plate 120, a second paper guide plate 130, a rack movement mechanism (not shown) and a plurality of sensing members (not shown). The first paper guide plate 120 includes a first paper stopping slice 1201, a first rack 1202 and a rib (not shown). The second paper guide plate 130 includes a second paper stopping slice 1301 and a second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com