Asynchronous non-constant-pitch spiral scroll-type fluid displacement machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

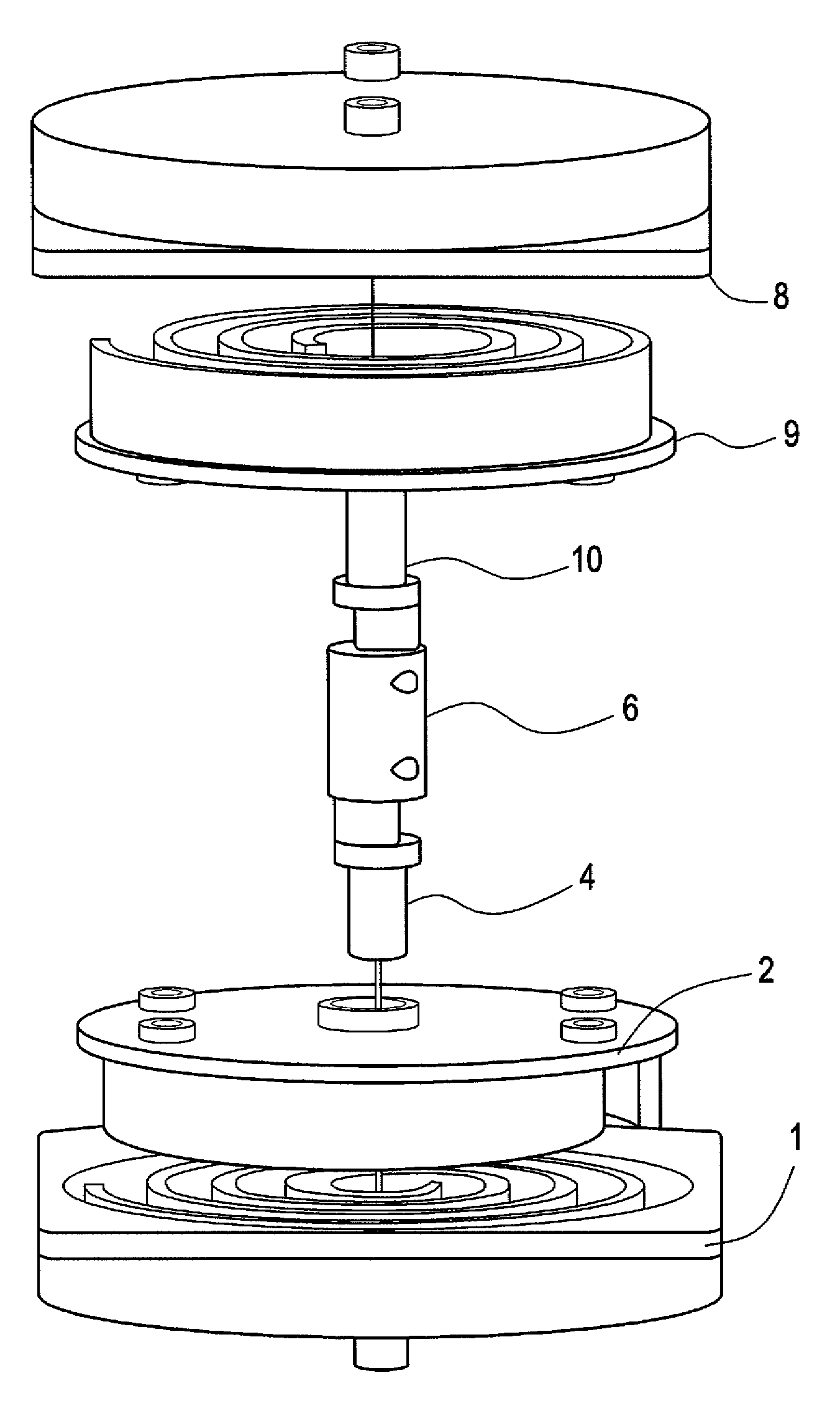

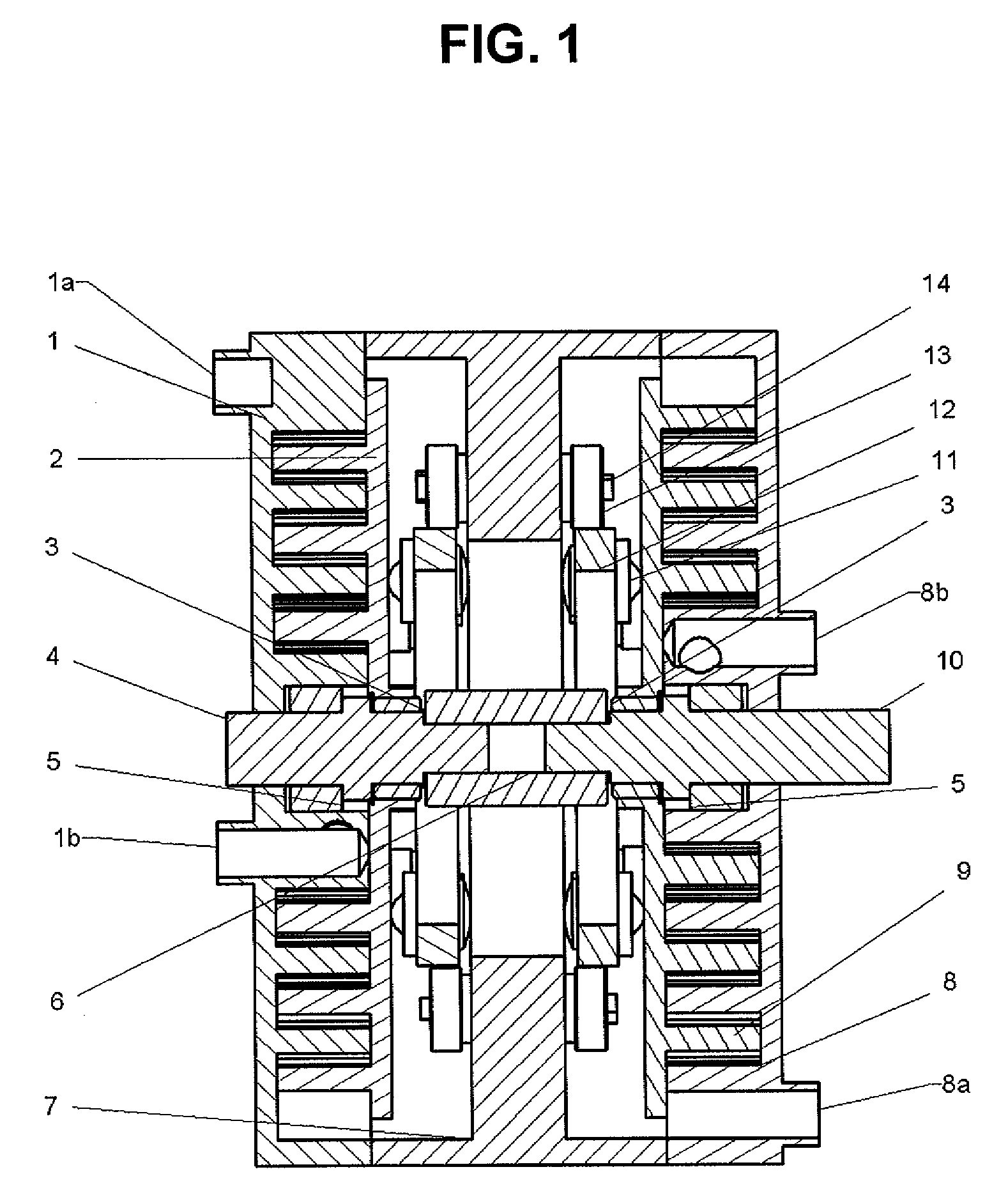

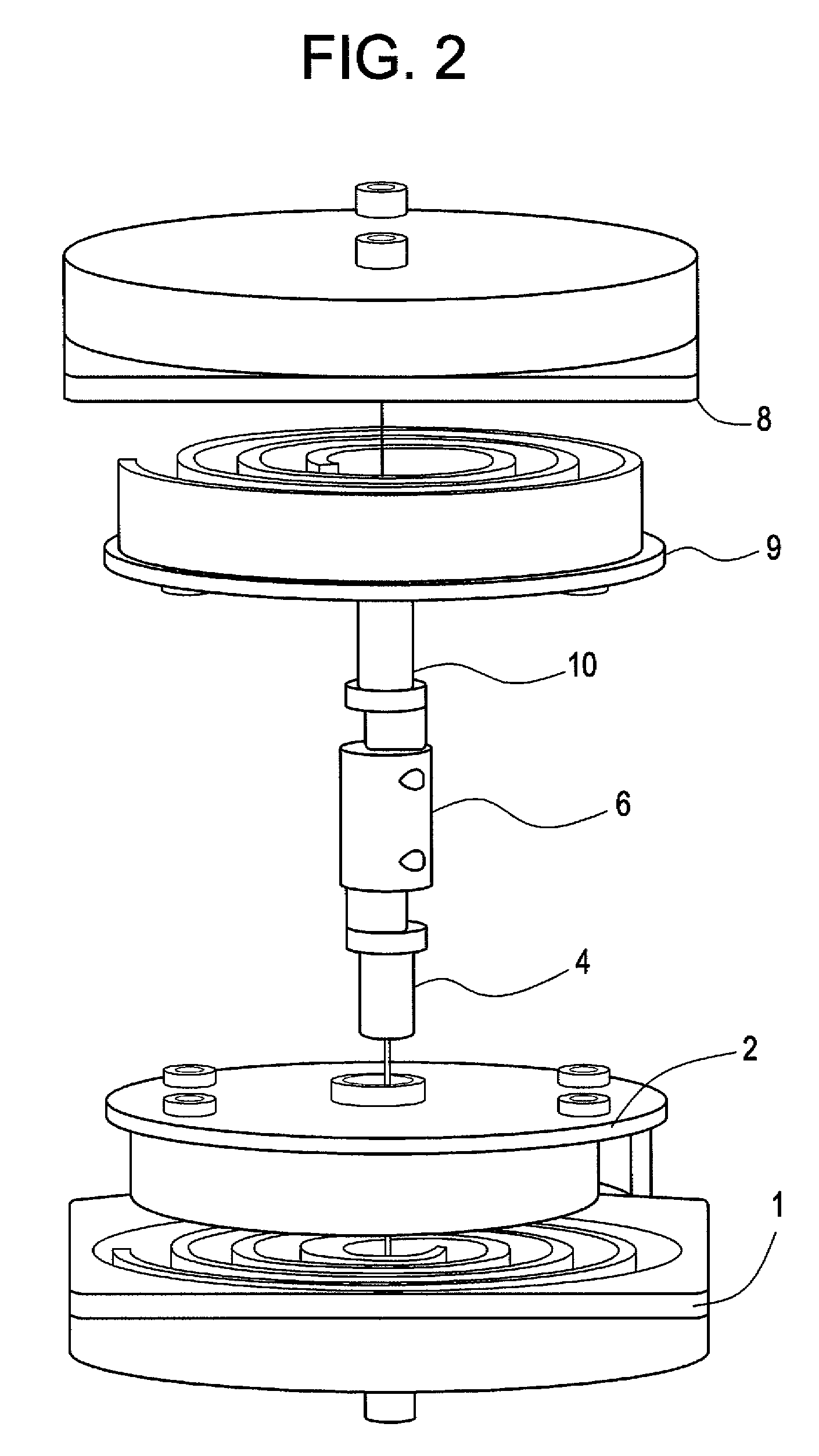

[0025]Referring to FIG. 1, the first fixed scroll 1 has its spiral wrap that interfits the spiral wrap of the first orbiting scroll 2. The concentric part of crankshaft 4 passes through the center hole of fixed scroll 1 and is supported by bearing 5 while the eccentric part of crankshaft 4 goes through the center hole of orbiting scroll 2 and is supported by bearing 3. The second fixed scroll 8 has its spiral wrap that interfits the spiral wrap of the first orbiting scroll 9. The concentric part of crankshaft 10 passes through the center hole of fixed scroll 8 and is supported by bearing 5 while the eccentric part of crankshaft 10 goes through the center hole of orbiting scroll 9 and is supported by bearing 3. The rigid coupling 6 connects crankshaft 4 and crankshaft 10. The fixed scroll 1 and fixed scroll 8 are affixed to the housing 7. The rotating force is transmitted to the end of crankshaft 10 so that the crankshaft 10 drives the orbiting scroll 9 to produce relative orbiting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com