Embedded magnet type motor

a technology of embedded magnets and motors, which is applied in the direction of magnetic circuits, electrical devices, dynamo-electric machines, etc., can solve the problems of reducing excessive leakage fluxes passing through the outer bridges, and increasing the number of parts, so as to reduce the effective flux of embedded magnet motors, increase torque, and prevent an increase in the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

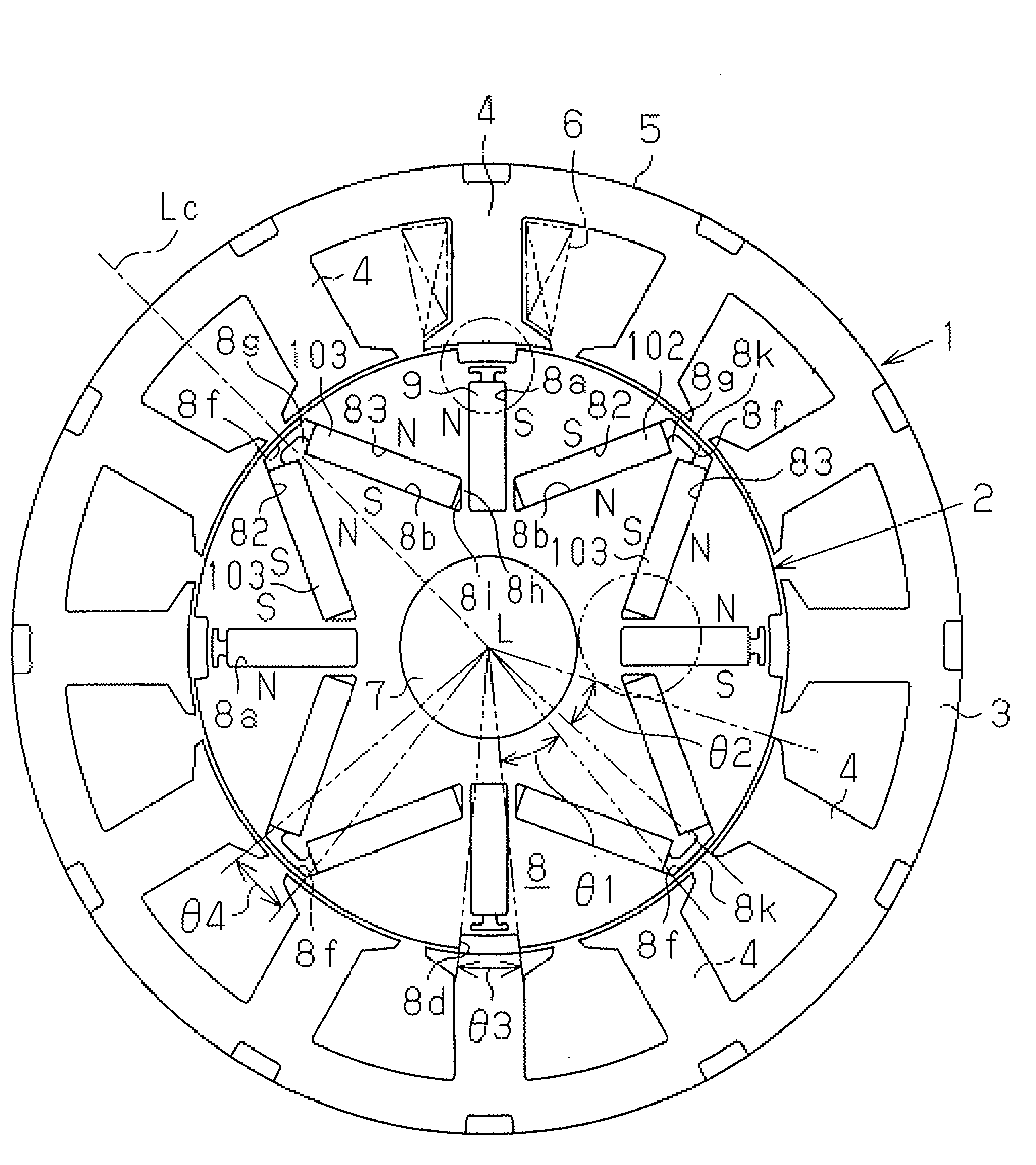

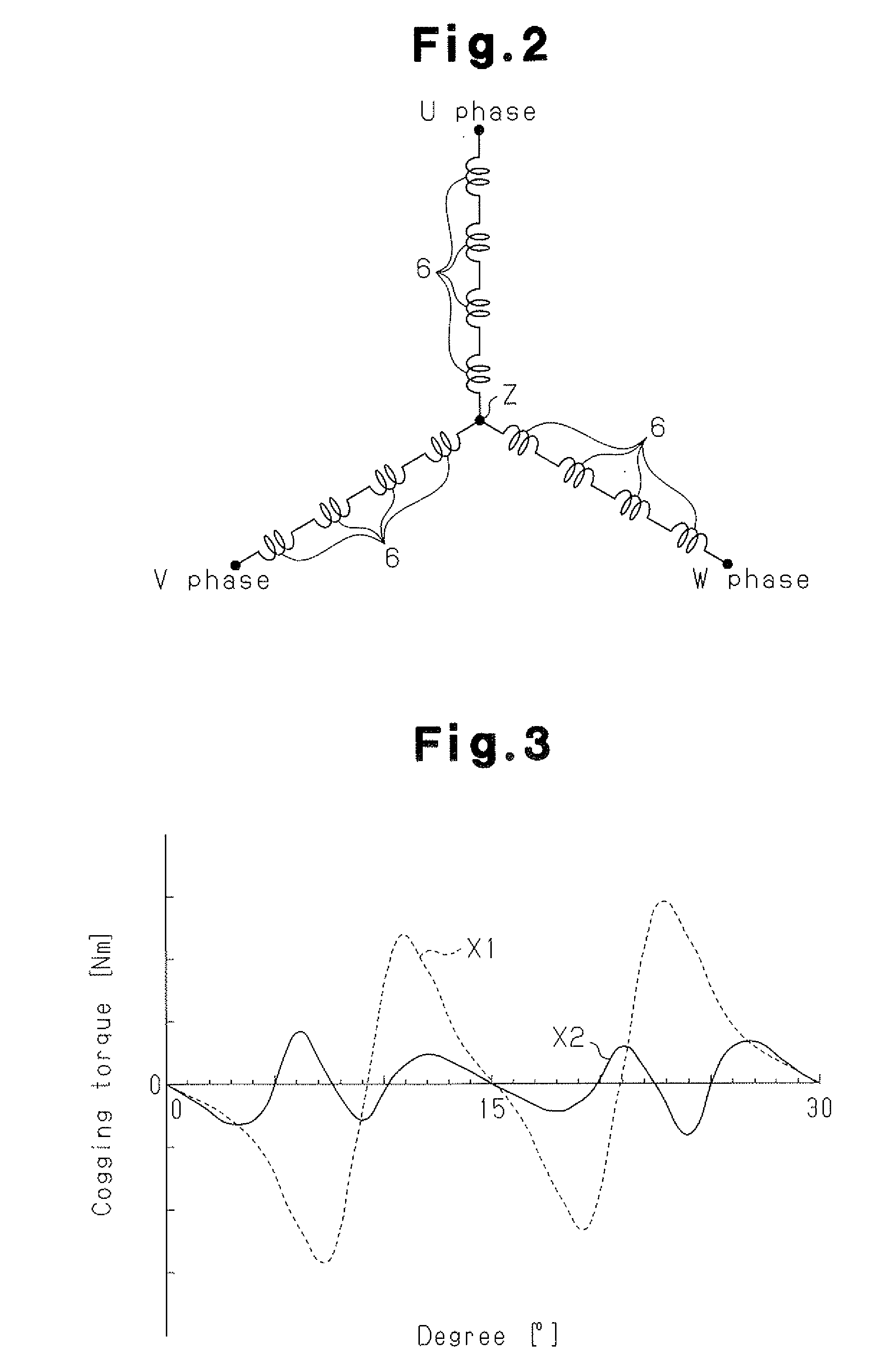

[0027]Hereinafter, an embodiment of the present invention will be described with reference to FIG. 1A through FIG. 3. As shown in FIG. 1A, an embedded magnet type motor includes a stator 1 and a rotor 2.

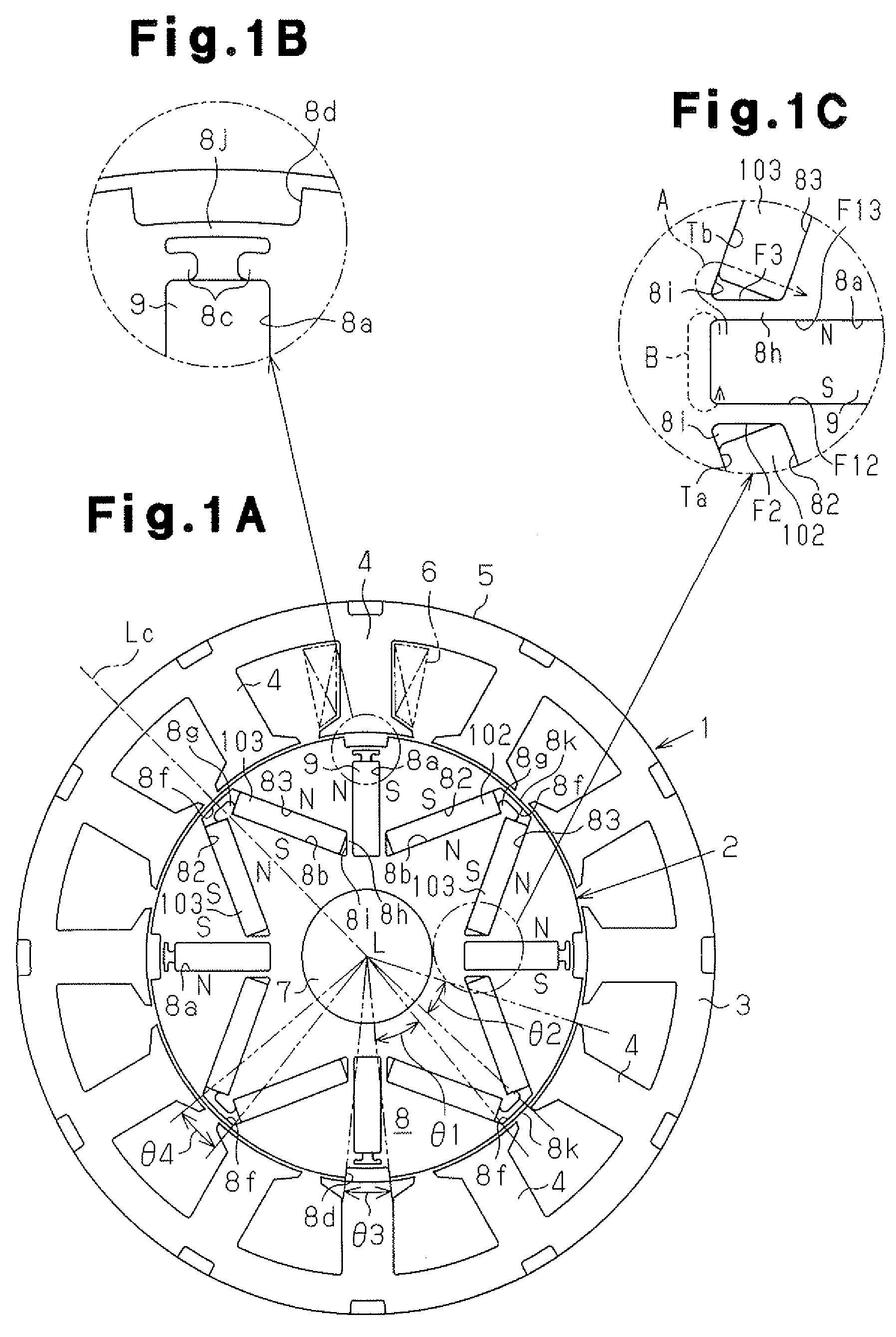

[0028]The stator 1 is cylindrical as a whole. The stator 1 includes a stator core 5 and a plurality of coils 6. The stator core 5 has a cylindrical portion 3 forming an outer shape and a plurality of teeth 4 arranged at equiangular intervals in the circumferential direction on the inner peripheral surface of the cylindrical portion 3. Each of these teeth extends toward the axial line L of the stator 1 from the inner peripheral surface of the cylindrical portion 3, that is, toward the radially inner side of the cylindrical portion 3. Each of the coils 6 is concentrically wound around a corresponding tooth 4 with an insulator (not shown). In FIG. 1A, one coil 6 is shown by an alternate long and short double-dashed line. The stator core 5 of this embodiment includes twelve teeth 4. As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com