Carton having modified end flaps for improved stacking strength and including easy opening feature

a technology of end flaps and cartons, applied in the field of packaging, can solve the problems of reducing profits, difficult storage and use for consumers, and assuming that individual products packaged within the cartons are damaged, and achieve the effect of improving the stacking strength of the carton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

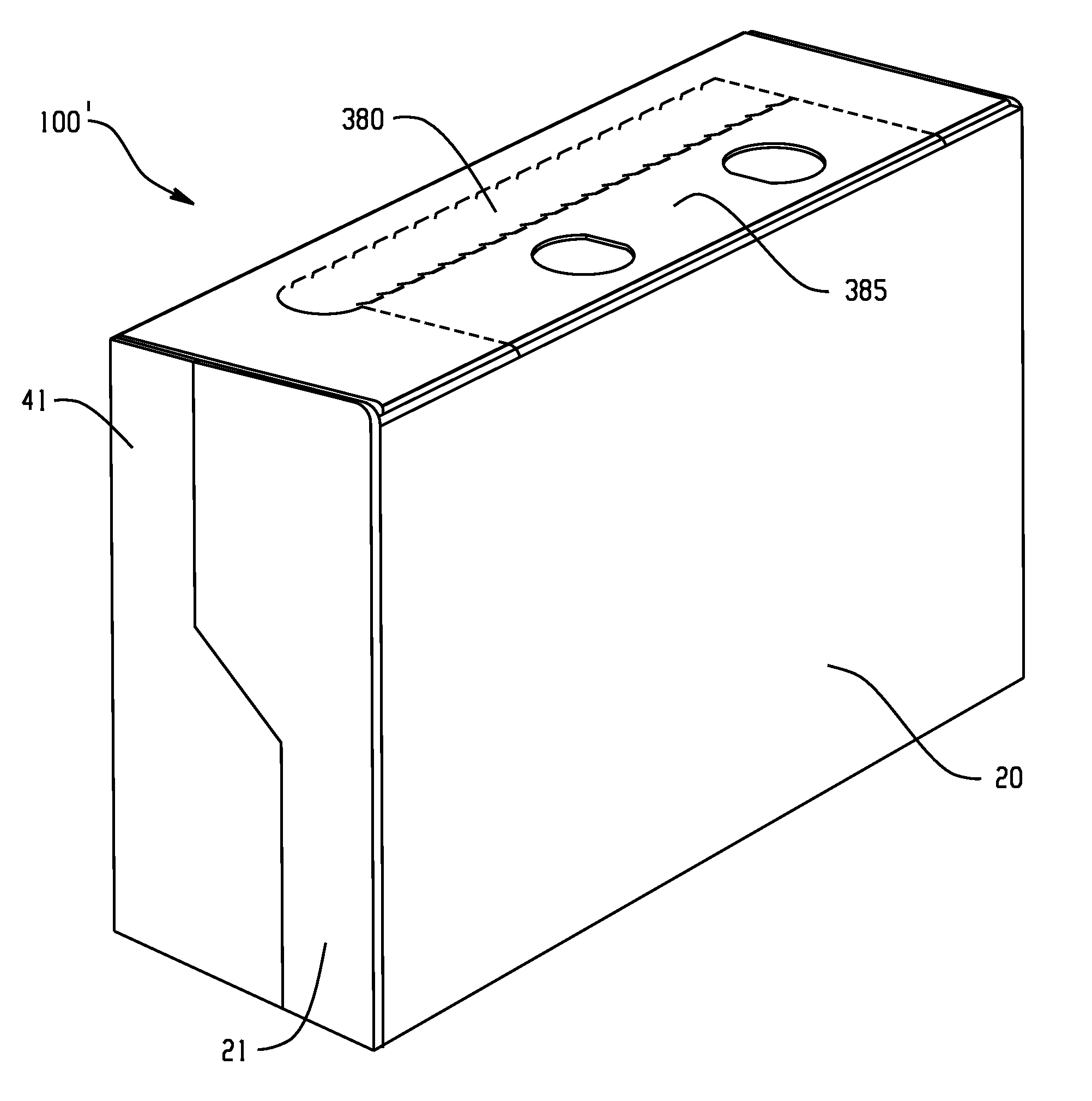

[0029]As shown in FIGS. 3 through 5, the easy opening feature of this invention includes a two part opening. This two part opening includes a tear strip 380 and an opening flap 385. Tear strip 380 is a standard feature of paperboard cartons and is used to provide the consumer with a mechanism to easily open carton 100′. As seen in FIG. 3, tear strip 380 extends along a generally middle or middle right portion of top panel 50. Opening flap 385 is adjacent to tear strip 380 along a middle left portion of top panel 50. The exact location of opening flap 385 and tear strip 380 is not critical. All that is necessary is that opening flap 385 and tear strip 380 are conveniently located along a portion of top panel 50 to provide easy access by the consumer to the contents of the carton. Opening flap 385 is bounded at its right side by the left side of tear strip 380, along its top by perforation line 390, along its bottom by perforation line 391 and along its left side by a portion of fourt...

third embodiment

[0030]As shown in FIGS. 6 through 8, the easy opening feature of this invention includes a single opening door 401, which is generally located in the middle or middle left portion of top panel 50. The exact location of opening door 401 is not critical. All that is necessary is that opening door 401 be conveniently located along top panel 50 to provide the consumer with easy access to the contents of the carton. As shown in FIG. 6, opening door 401 is bounded on its right side by perforation line 530, along its top by curved perforation line 520, along its bottom by perforation line 510 and along its left side by a portion of fourth vertical fold line 240. As discussed in more detail below, preferably, that portion of fourth vertical fold line 240 that extends between perforation line 510 and perforation line 520 is perforated. This allows opening door 401 to be completely removed from the carton. Horizontal perforation lines 501 and 502 extend across a top portion, as seen in FIG. 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com