Paper barrel opening edge reeling machine

A technology of curling machine and barrel mouth, which is used in paper/cardboard containers, envelope/bag manufacturing machinery, containers, etc., can solve the problems of many peripheral height errors, low strength, easy to have waste paper cutting, etc., and achieve the peripheral height error. Small, good effect of improving compressive strength and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

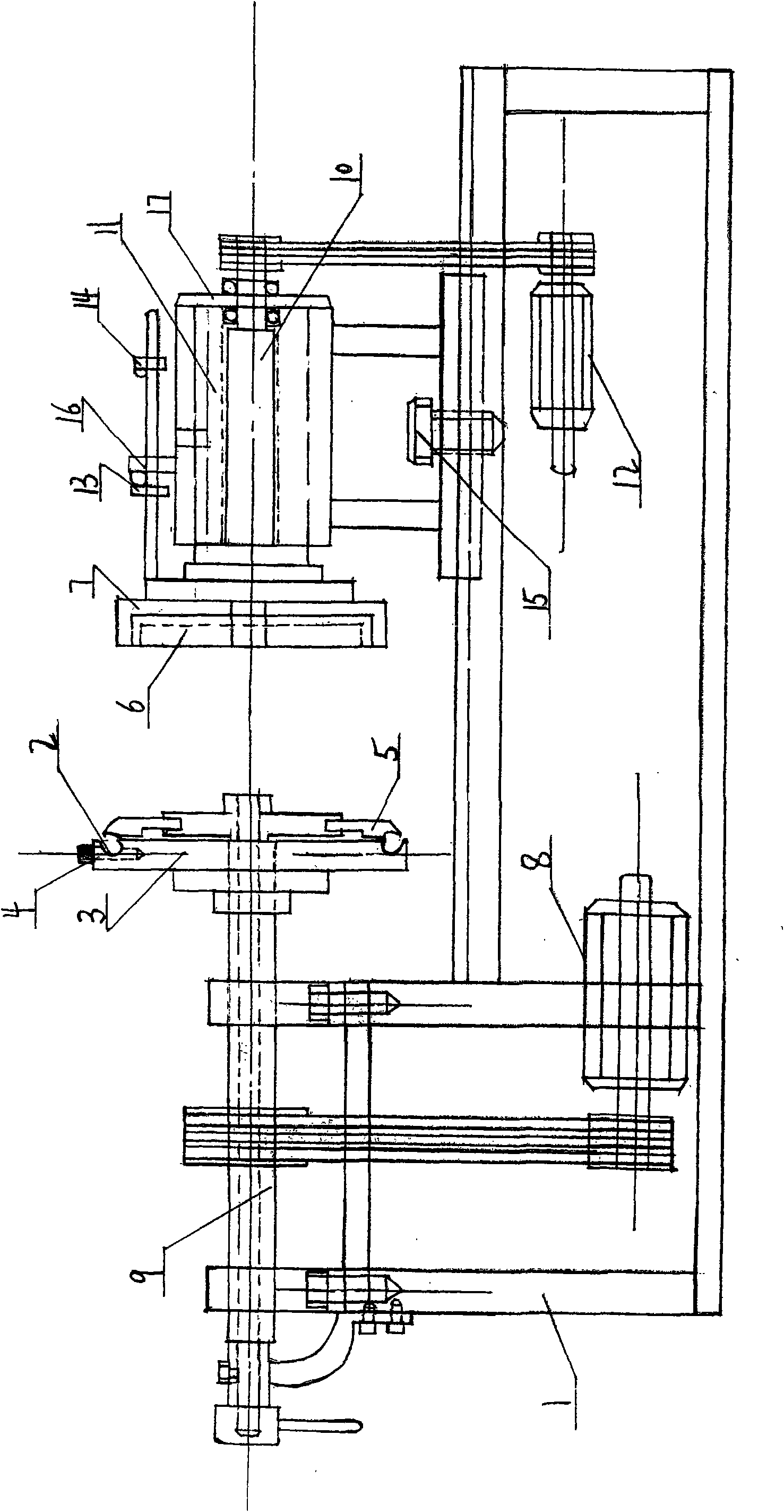

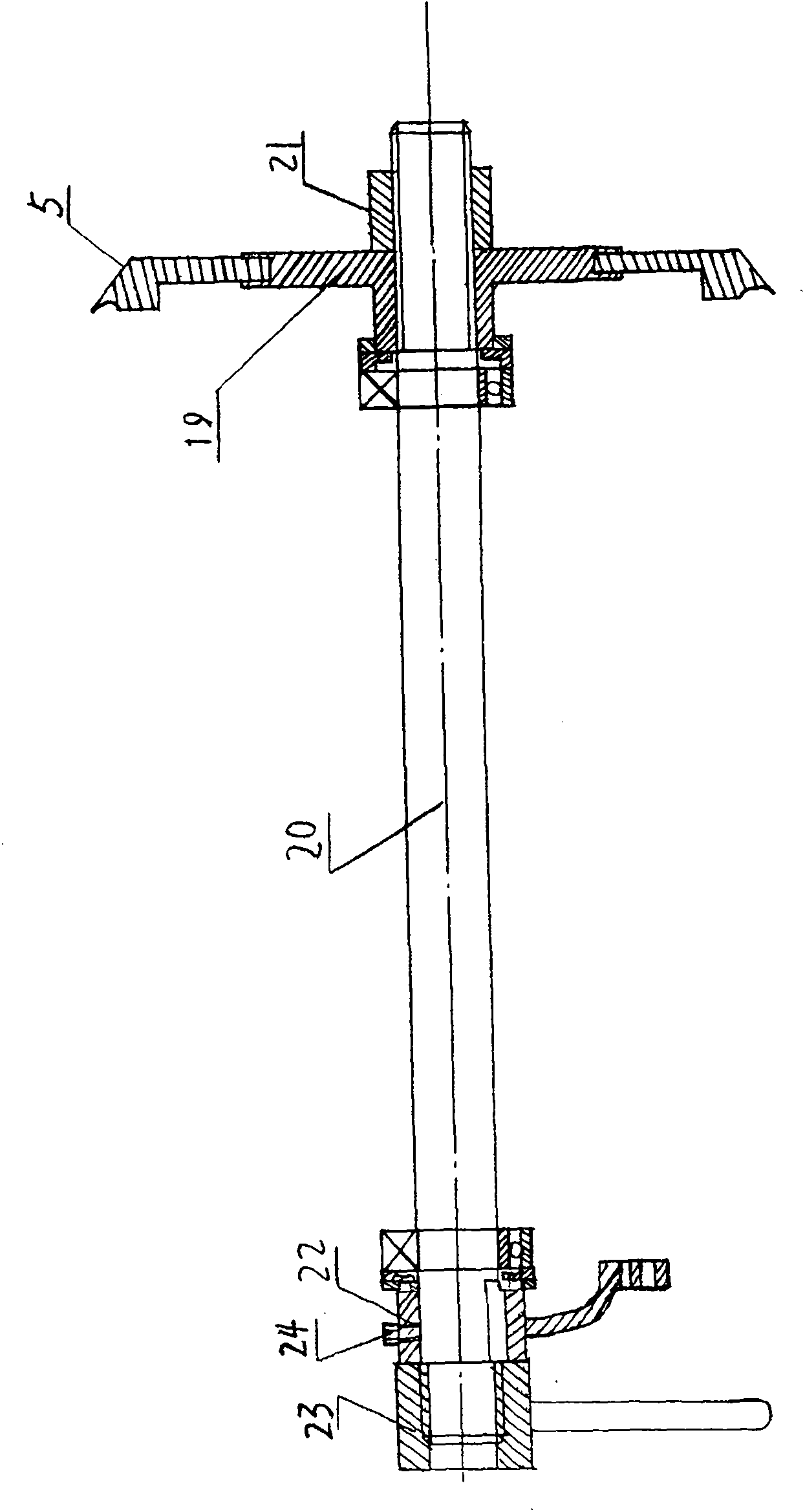

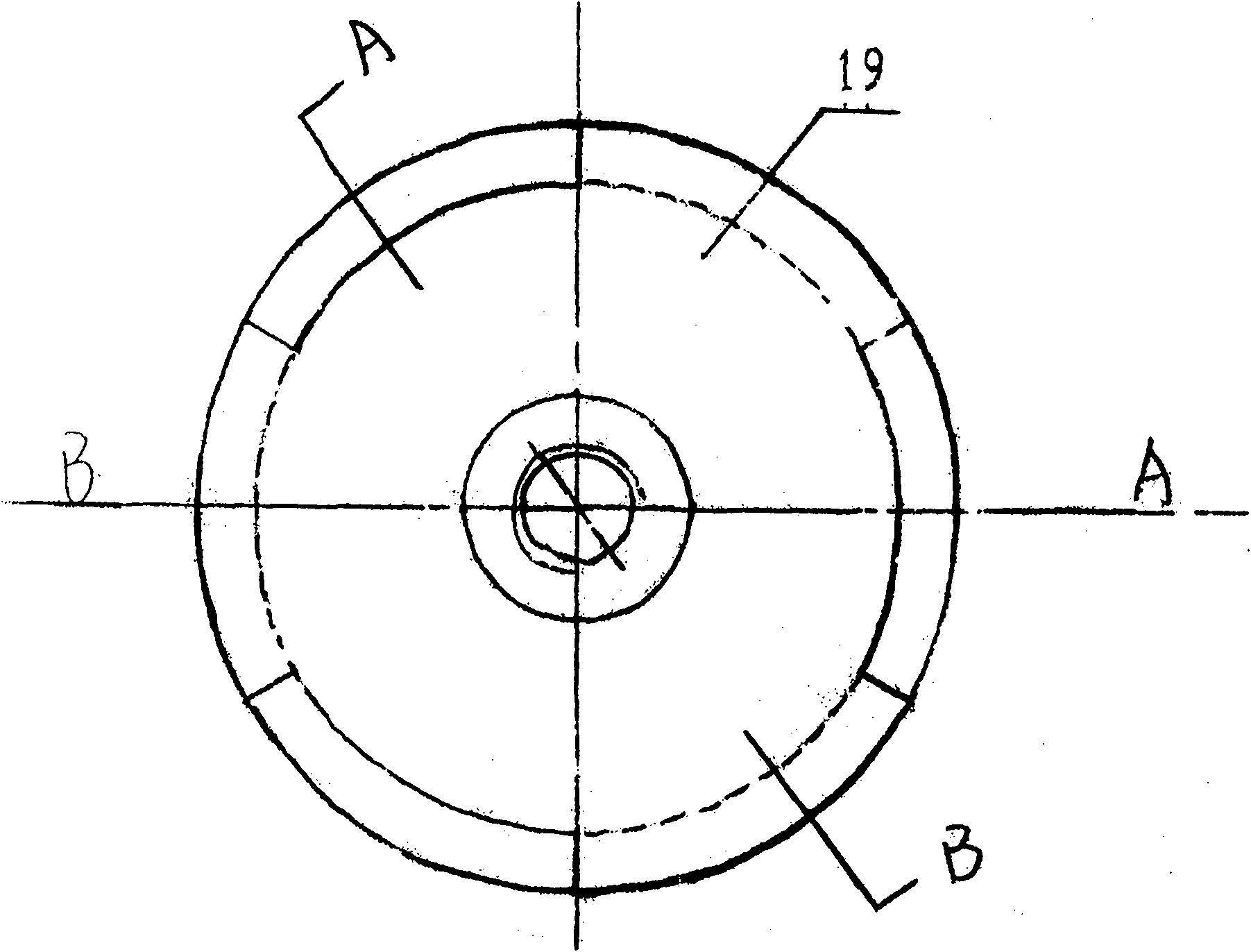

[0012] figure 1 Among them, at the left end of frame 1, a 6-stage 5 kilowatt motor 8 is equipped with a center shaft 9 driven by a left and right horizontal rotation speed of 350-400 rev / min, and the right end of center shaft 9 is equipped with an elbow mold 3, which bends The head mold 3 is connected with the central shaft 9 and rotates thereupon, and the elbow mold 3 has an arc groove 2 near the outer diameter position on the right plane, and 6 convex ribs are evenly distributed in the arc groove. An edge curling control panel 5 is installed outside the arc groove 2 of the elbow mold 3, and the edge curling control panel 5 has an arc arranged opposite to the arc groove 2, and the arc and the arc of the arc groove 2 together form a clamping A device that holds and limits the bezel of the bung mouth. Said curling control disc 5 is loaded on the mandrel 20 through the connection plate 19, and the mandrel 20 is sleeved in the central shaft 9 to be consistent with the central ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com