Fixed Abrasive Pad Having Different Real Contact Areas and Fabrication Method Thereof

a technology of fixed abrasives and real contact areas, which is applied in the direction of dough shaping, manufacturing tools, applications, etc., can solve the problems of reducing the yield of semiconductor devices, consuming a relatively large working time, and disabling or disfiguring the minute surface topology of the roller, so as to reduce or prevent adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

A First Embodiment

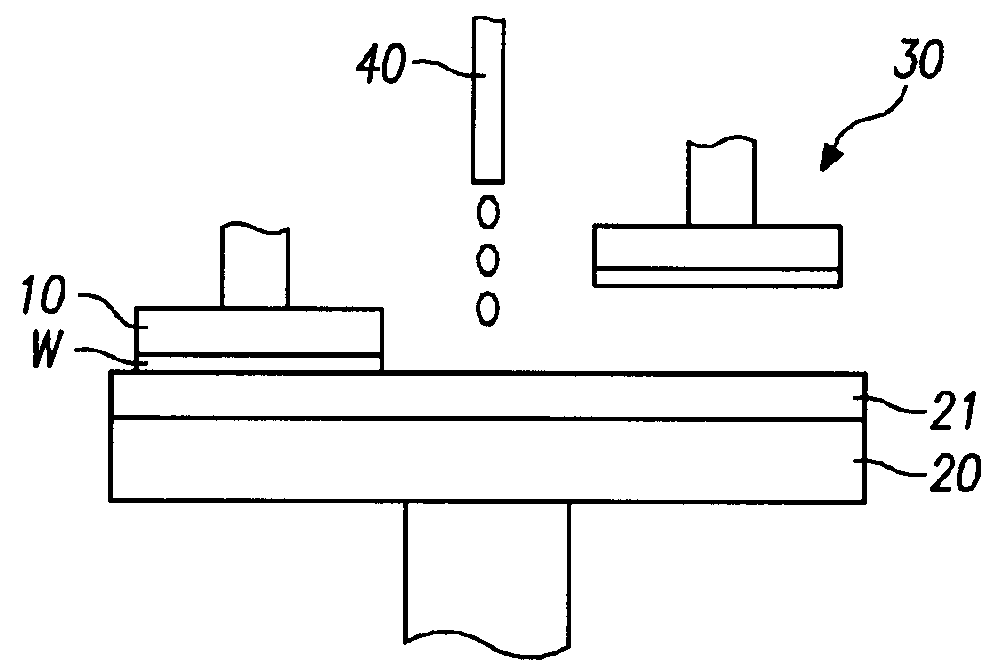

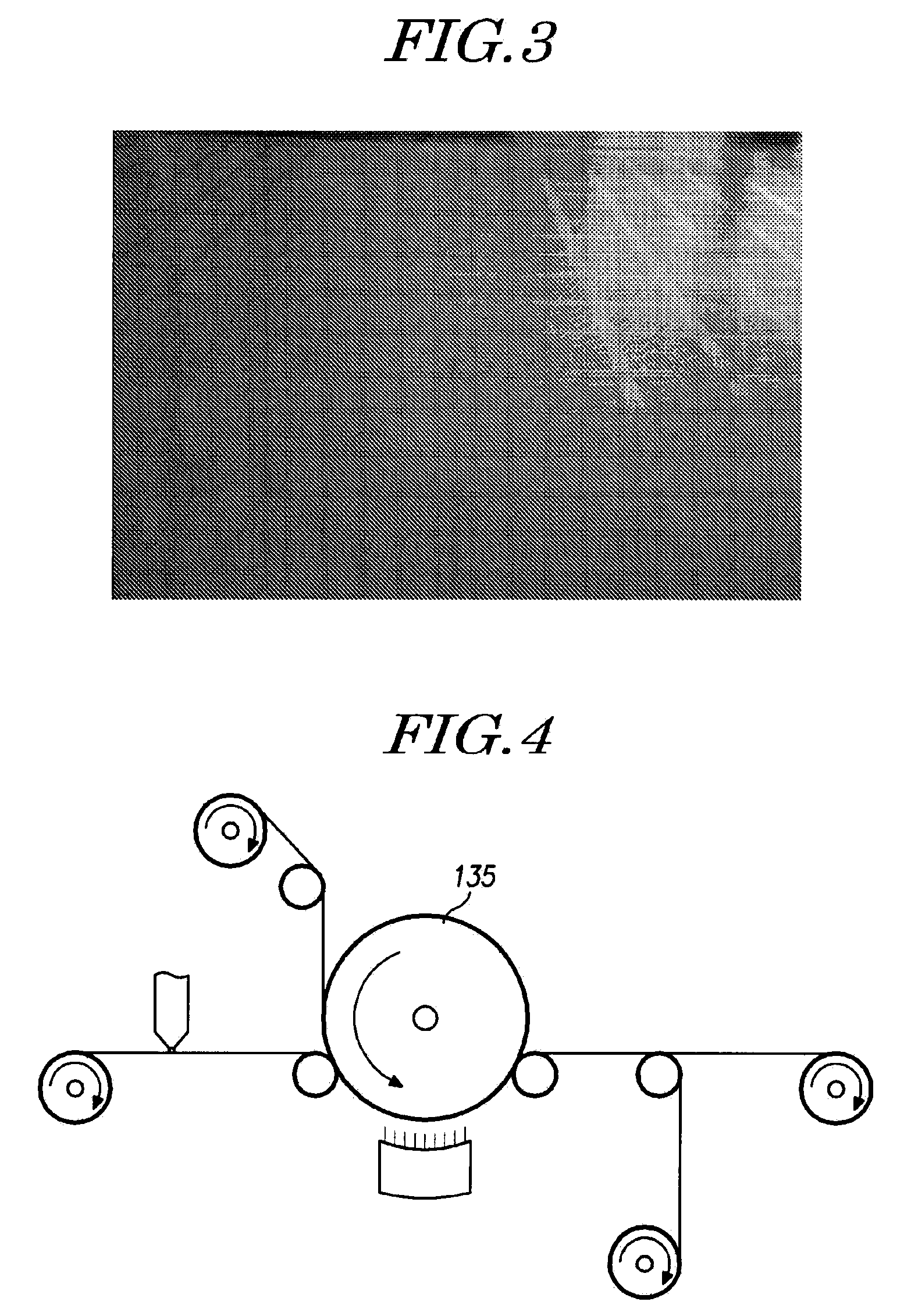

[0028]Firstly, an etching mold is formed, having a surface morphology opposite or complementary to the shape that is desired on a surface (e.g., the polishing surface) of the polishing pad. An exemplary etching mold is shown in FIG. 3. A metal material such as stainless steel is etched using a metal etching technique to form the mold, such as that shown in FIG. 3. The etching molds may be formed in at least two separate pieces, wherein one etching mold provides a polishing pad or pad region that has a different real contact area from another polishing pad or pad region. Alternatively, the mold may be formed in one unitary piece.

[0029]Next, the etching mold(s) providing different real contact areas are attached to a surface of roller. Preferably, the roller includes through-holes whereby a vacuum can be applied (e.g., to the inside of the roller), and the etching molds may be attached to the surface of the roller by a vacuum absorption mechanism.

[0030]A fixed abrasi...

second embodiment

A Second Embodiment

[0035]The second embodiment of a method for fabricating a fixed abrasive pad having different real contact areas utilizes a press.

[0036]Firstly, a mixture of abrasive particles, a binding agent, and (optionally) a hardening agent is applied on a polycarbonate film constituting a base of the fixed abrasive pad, and then a polishing film is formed by a rolling method using a roller. Here, the roller has no surface morphology, and the polishing film is temporarily hardened in a constant thickness. Next, the etching molds having different real contact areas are respectively attached to a press.

[0037]Subsequently, the temporarily hardened polishing film is positioned on the press, and then is pressed or deformed by the press under a predetermined heat and pressure. After then, the polishing film is cooled, thus forming a fixed abrasive pad having one or more regions of relatively low real contact area and one or more regions of relatively high real contact area.

[0038]F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| real contact area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com