Panel-type input device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The embodiments of the present invention are described below in detail, with reference to the accompanying drawings. In the drawings, the same or similar components are denoted by common reference numerals.

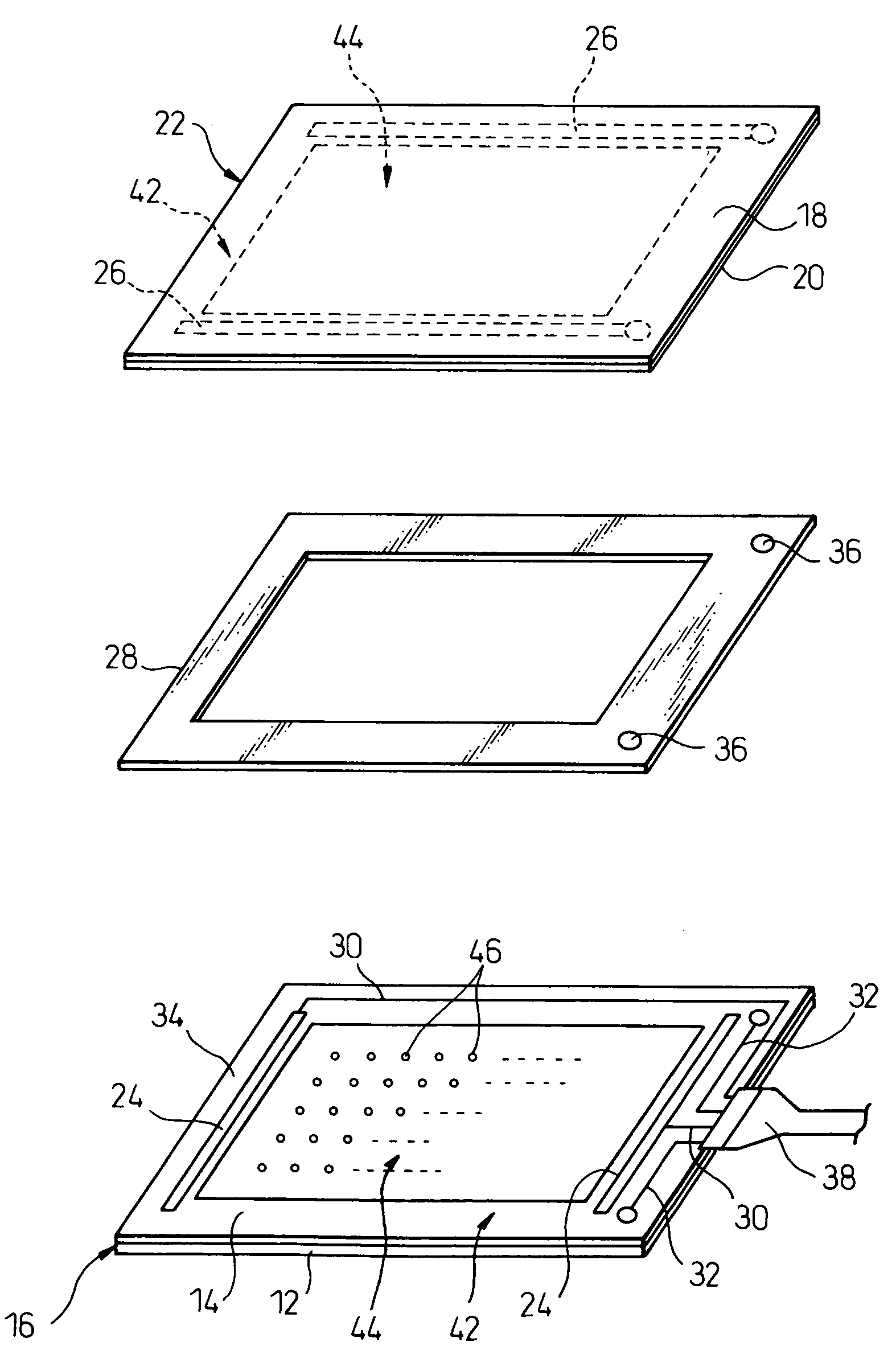

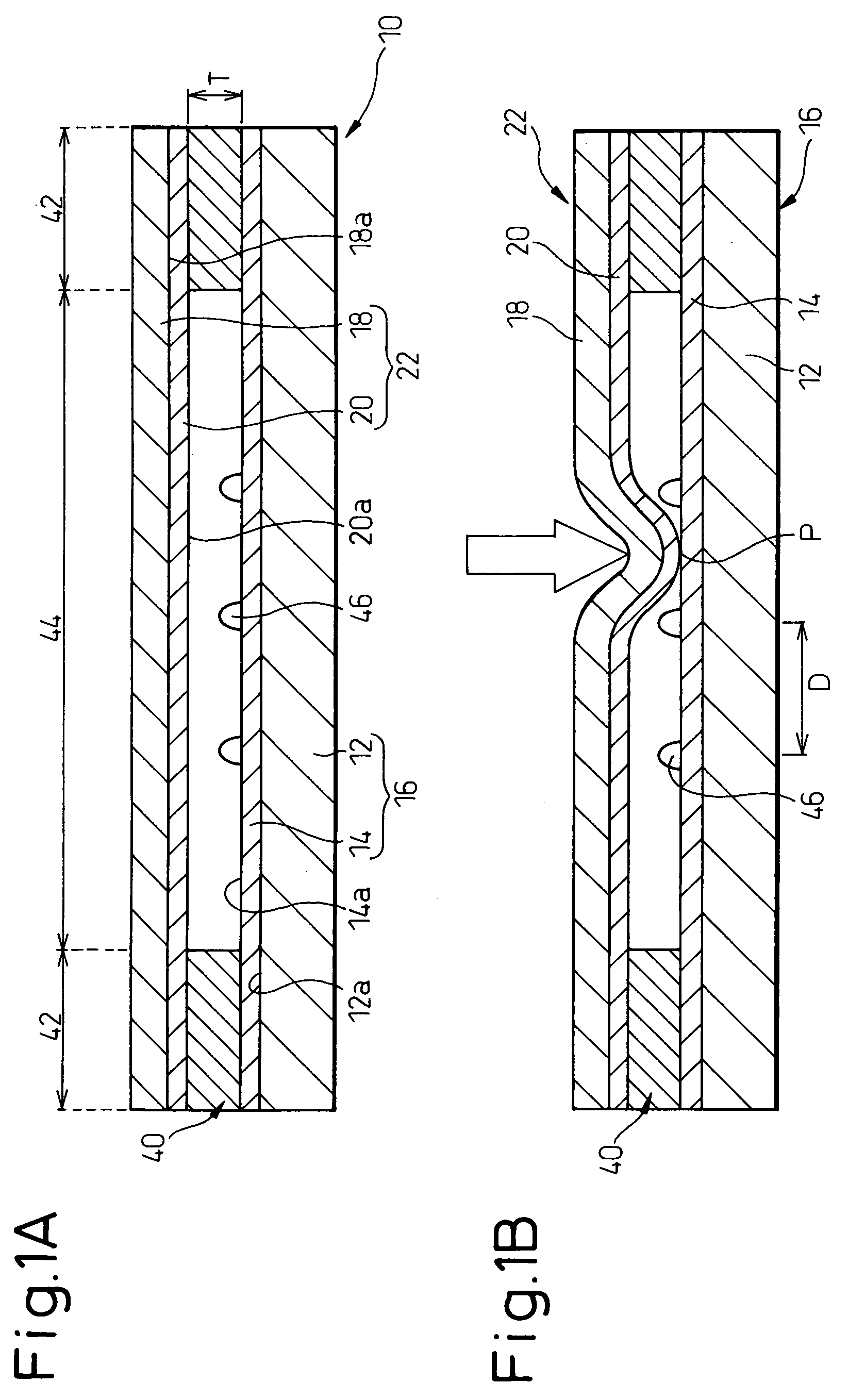

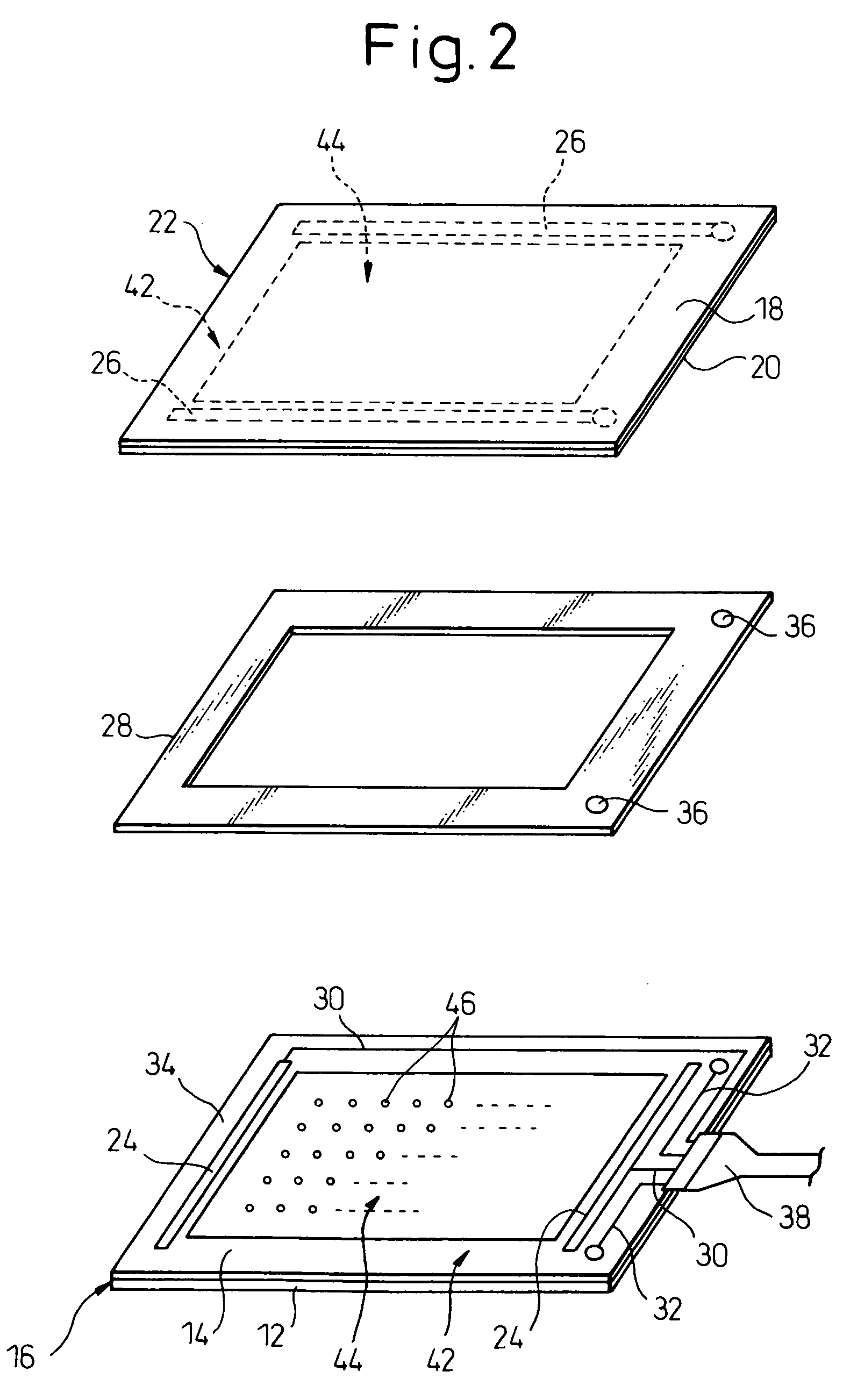

[0020]Referring to the drawings, FIGS. 1A and 1B show, in schematic sectional views, essential components of a panel-type input device 10 according to a first embodiment of the present invention in non-operated and operated states, and FIG. 2 shows, in an exploded schematic perspective view, the essential components of the panel-type input device 10.

[0021]The panel-type input device 10 includes a first electrode plate 16 having a first electrical-insulating substrate 12 and a first electrical-conductive coat 14 provided on a surface 12a of the first substrate 12, a second electrode plate 22 having a second electrical-insulating substrate 18 and a second electrical-conductive coat 20 provided on a surface 18a of the second substrate 18. The first substrate 12 and first conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com