Light-emitting diode structure

a technology of light-emitting diodes and leds, which is applied in the direction of semiconductor devices, printed circuit aspects, solid-state devices, etc., can solve the problems of troublesome and inconvenient mounting of conventional leds to power supply boards, unfavorable disassembly or replacement of conventional leds, etc., and achieves convenient replacement and mounting. easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

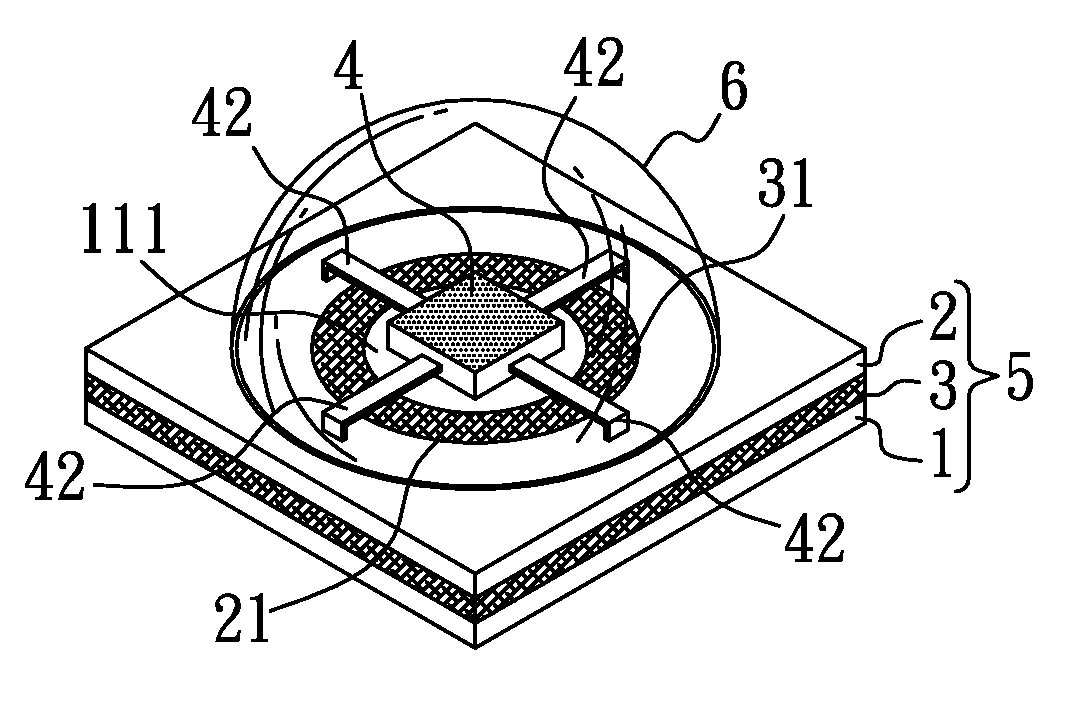

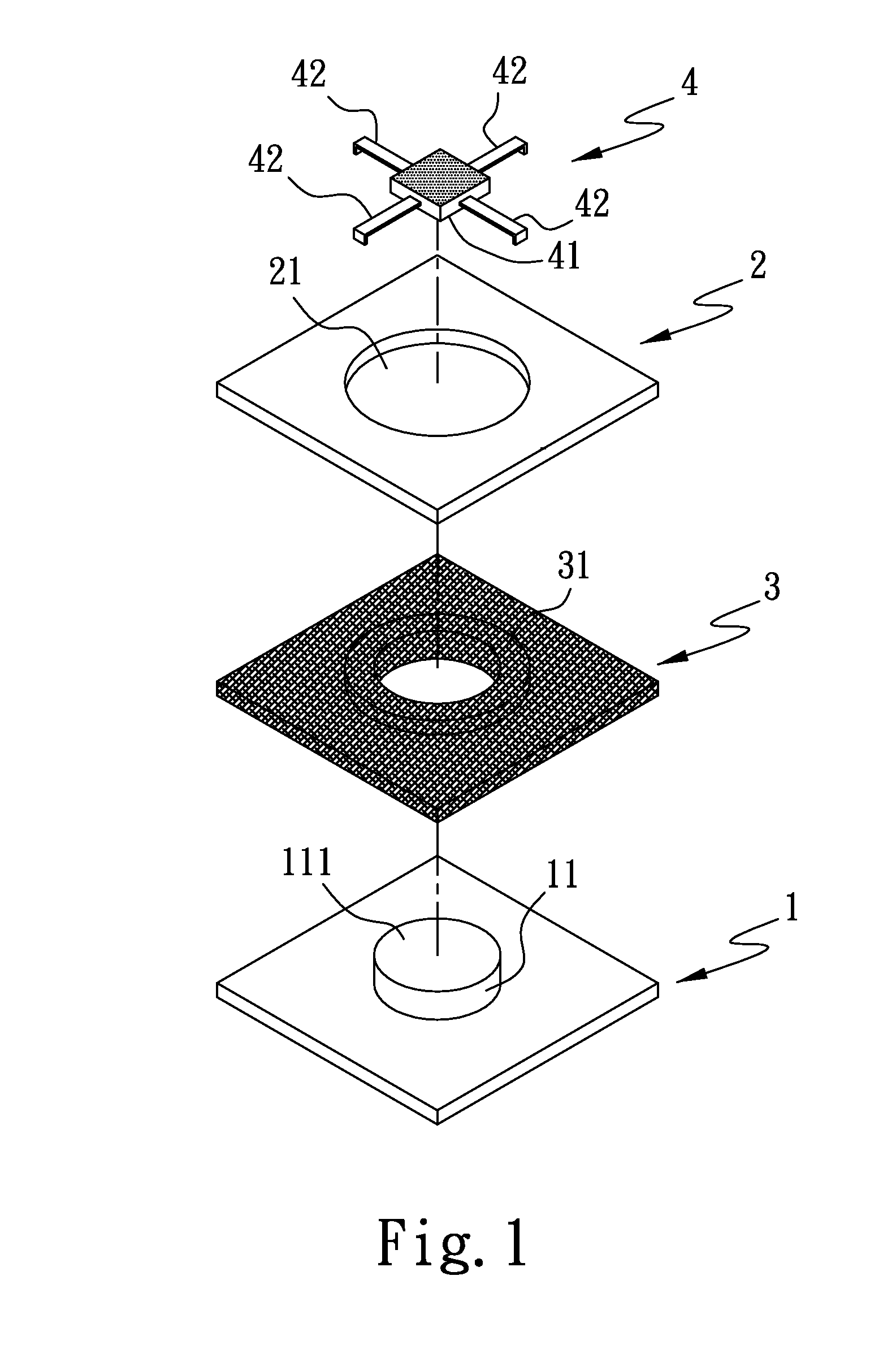

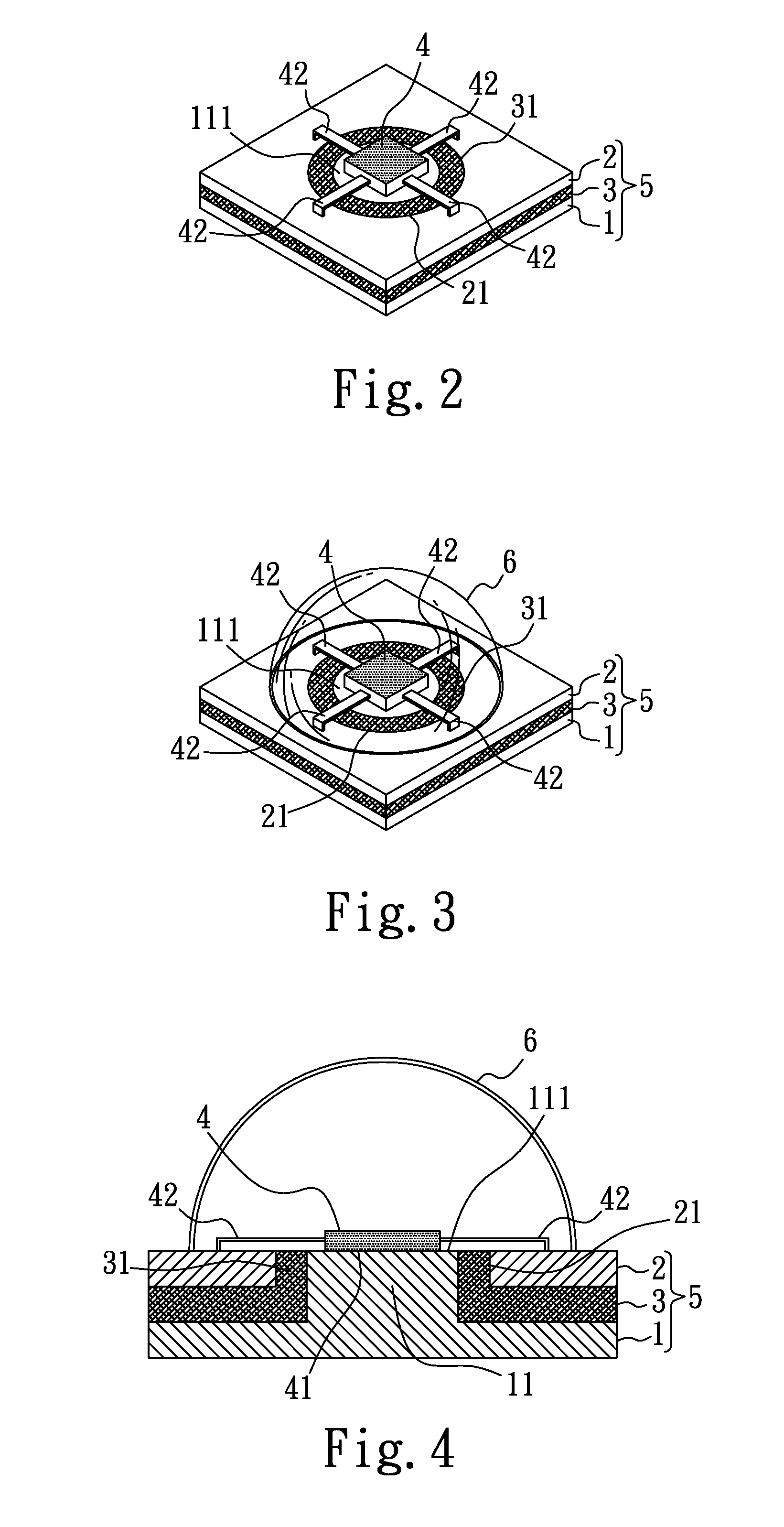

[0030]Please refer to FIGS. 1 and 2 that are exploded and assembled perspective views, respectively, of an LED structure according to a first preferred embodiment of the present invention. As shown, in the first preferred embodiment, the LED structure includes a first conductive body 1, a second conductive body 2, a first insulating body 3, and an LED 4.

[0031]The first conductive body 1 includes an upward projected conducting portion 11, which may be a cylindrical post.

[0032]The first insulating body 3 includes an insulating sleeve portion 31, which may be a hollow boss, such that the first insulating body 3 may be disposed on the first conductive body 1 with the insulating sleeve portion 31 fitted around the upward projected conducting portion 11. It is noted a conducting section 111 at a top of the projected conducting portion 11 is exposed at the sleeve portion 31.

[0033]The second conductive body 2 includes a through opening 21 and is disposed on the first insulating body 3, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com