Sheet-Discharging Apparatus for Sheet-Fed Printing Press

a technology of sheet-fed printing press and discharging apparatus, which is applied in the directions of transportation and packaging, thin material processing, and article delivery, etc., can solve the problems of inability to carry out cleaning operation of fan device, inability to easily remove flour or powder accumulated on the upper surface of the bracket, and inability to see the operator (personnel) easily, so as to improve the safety of the operator and facilitate the cleaning operation of the fan device. , the effect of improving the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

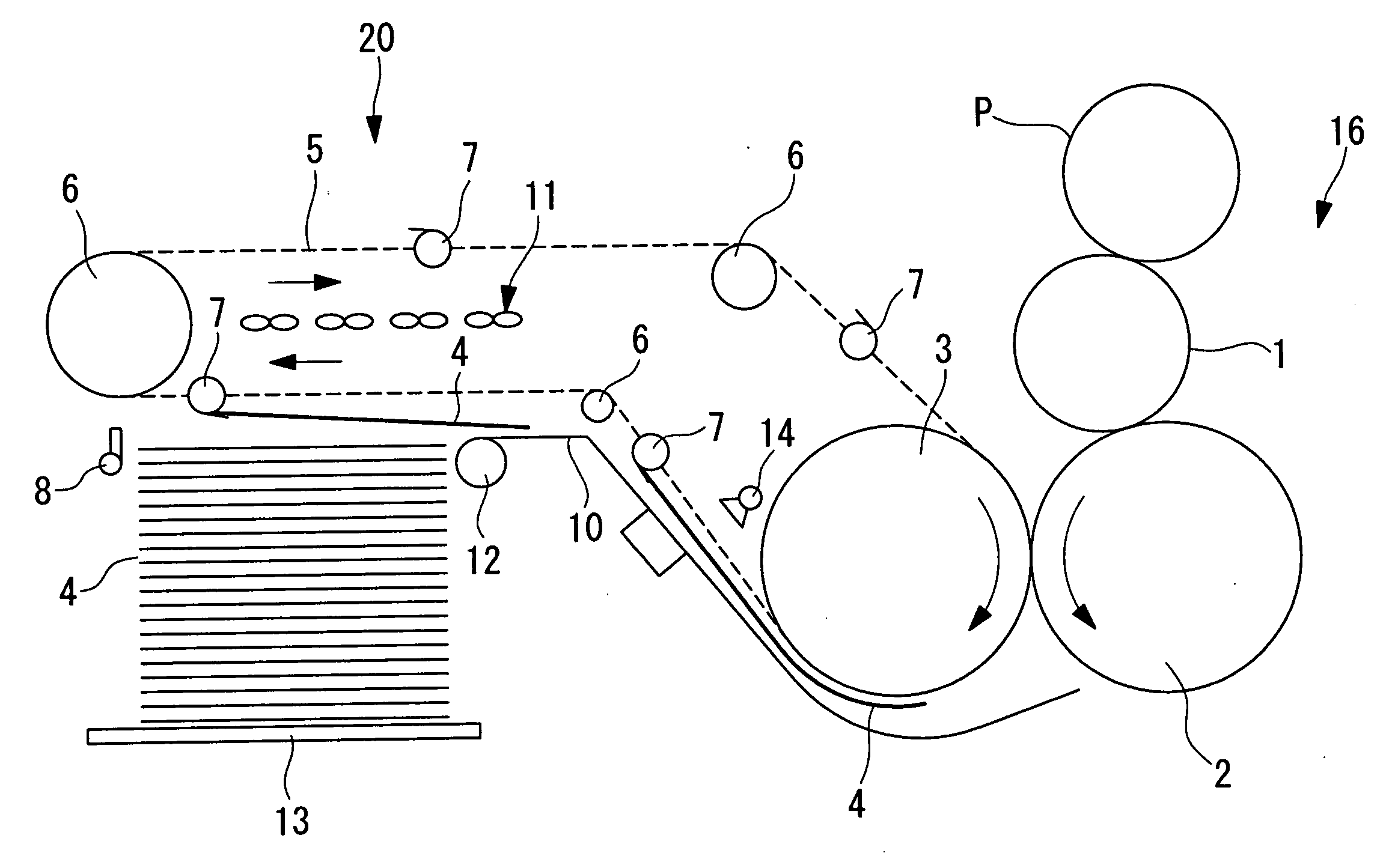

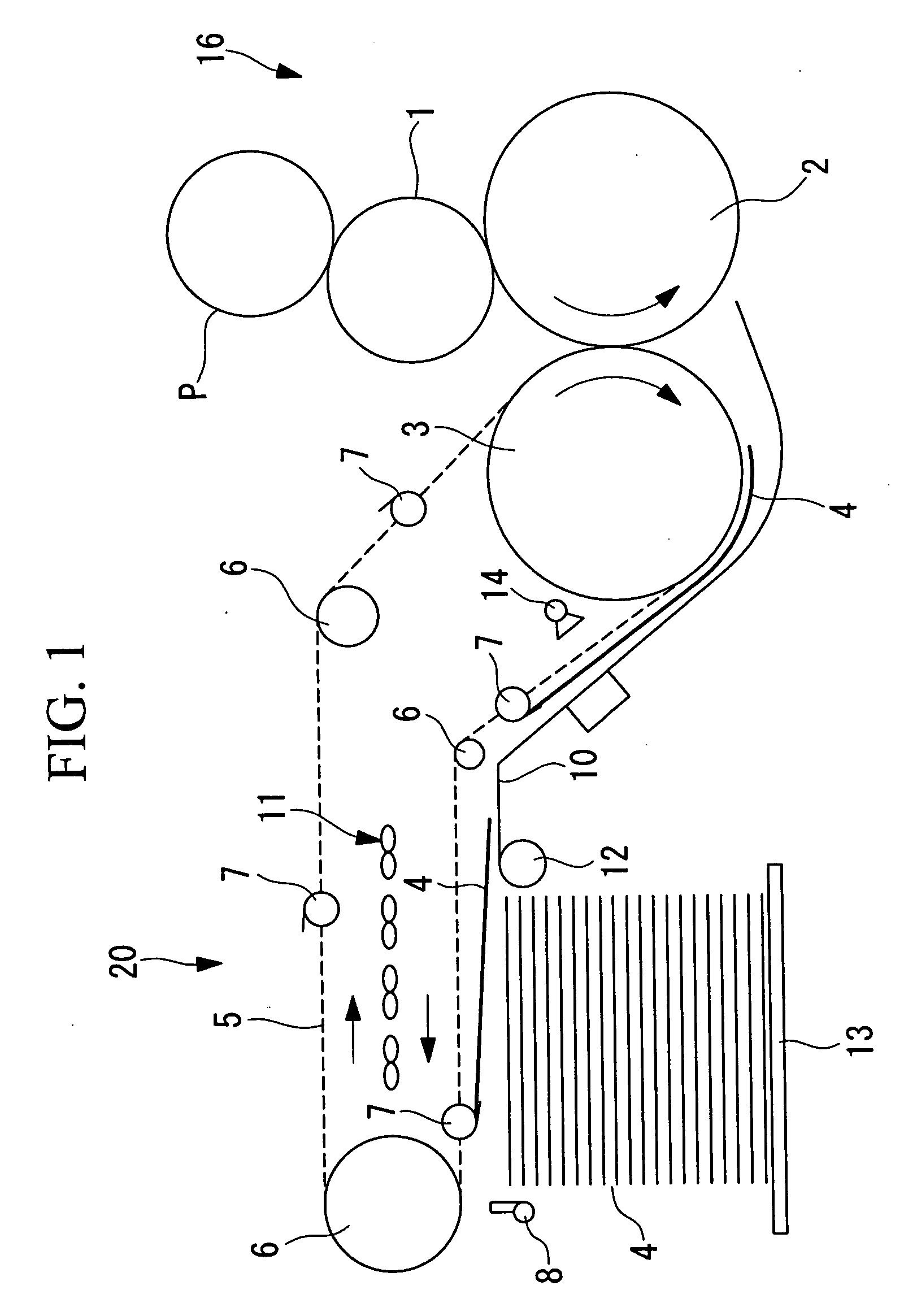

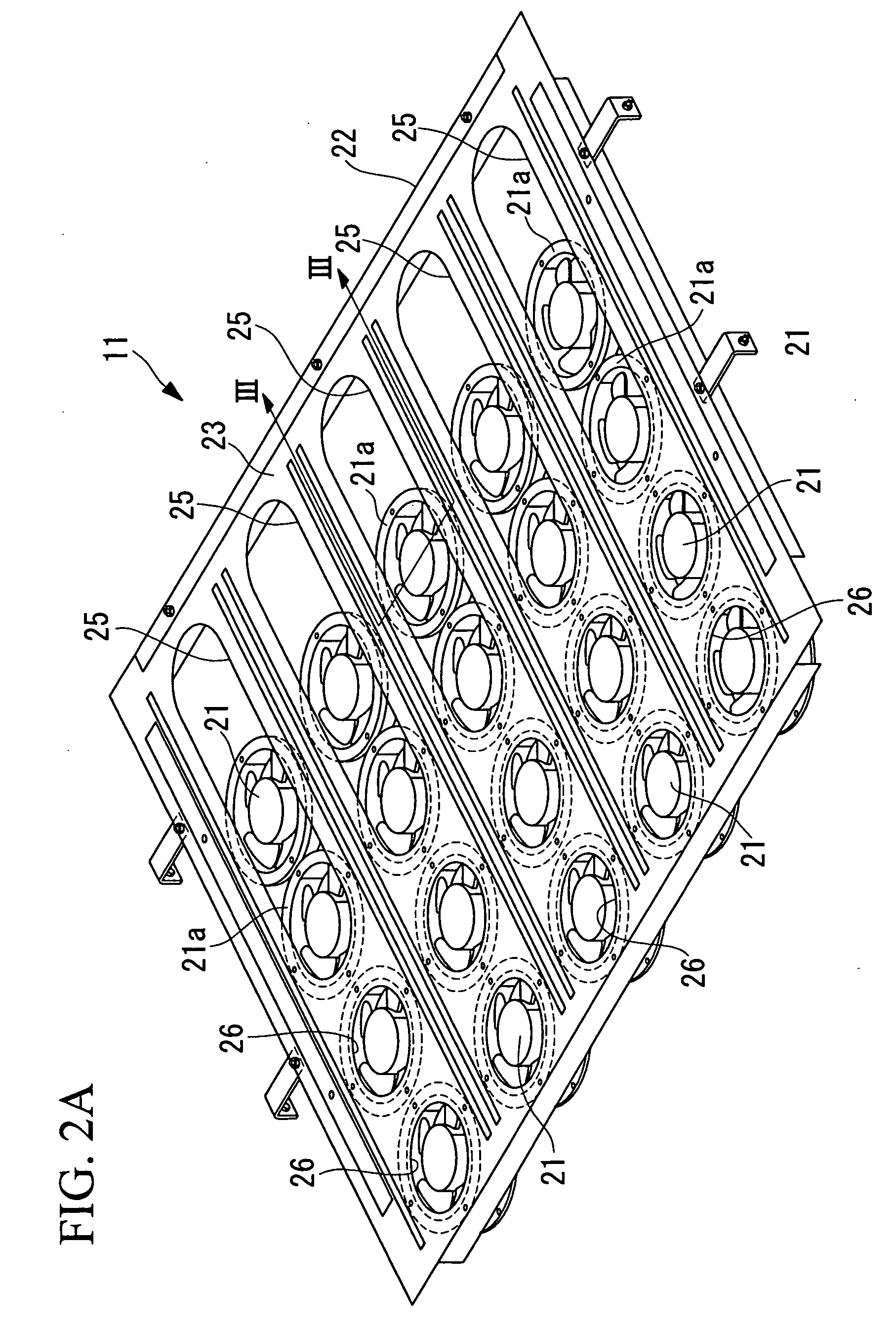

[0058]Referring now to FIG. 1 to FIG. 4, a sheet-discharging apparatus for a sheet-fed printing press according to the present invention will be described.

[0059]FIG. 1 is a general schematic block diagram of a sheet-fed printing press 100 provided with a sheet-discharging apparatus 20 for a sheet-fed printing press (hereinafter, referred to simply as “sheet-discharging device”), FIG. 2A and FIG. 4 are general perspective views of a fan device 11 shown in FIG. 1, FIG. 2B is a front view of the fan device 11 shown in FIG. 2A viewed from the lower left side of the drawing, and FIG. 3 is a cross-sectional view taken along the line III-III in FIG. 2A.

[0060]As shown in FIG. 1, the sheet-fed printing press 100 includes a sheet-feeding device (not shown), a printing apparatus 16 and the sheet-discharging apparatus 20.

[0061]The sheet-feeding device is a unit configured to allow sheets (for example, printing sheets) 4 as printed material to be stacked on a sheet-feeding table (not shown), and...

second embodiment

[0081]Referring now to FIG. 5, the sheet-discharging apparatus according to the present invention will be described.

[0082]The sheet-discharging apparatus in this embodiment is different from that in the first embodiment in that a fan device 31 including a plurality (five in this embodiment) of third openings 30 is provided instead of the fan device 11 having the second openings 26 and the second openings 26. Since other components are the same as those in the first embodiment, description of these components will be omitted here.

[0083]The third openings 30 are formed in an elongated shape so as to extend along the feeding direction from the upstream side to the downstream side of the frame body 23. The plurality of third openings 30 are arranged in line in the widthwise direction (the direction orthogonal to the feeding direction).

[0084]On the other hand, a plurality (ten in this embodiment) of the slide rails 24 (see FIG. 3) extending in the feeding direction along the both lateral...

third embodiment

[0088]Referring now to FIG. 6, the sheet-discharging apparatus in the present invention will be described.

[0089]The sheet-discharging apparatus in this embodiment is different from that in the first embodiment described above in that a fan device 41 having the first openings 25 and a plurality of (two in this embodiment) fourth openings 40 is provided instead of the fan device 11 having the first openings 25 and the second openings 26. Since other components are the same as those in the first embodiment, description of these components will be omitted here.

[0090]Although only one each of the blast fan 21 is drawn in the fourth openings 40 in FIG. 6, it is just for simplification of the drawing and, in practice, there are provided a plurality of (four, for example) blast fans 21, in each of the fourth openings 40.

[0091]The fourth openings 40 are formed in an elongated shape so as to extend along the widthwise direction from one side to the other side of the frame body 23. The plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com