Construction methods for backside illuminated image sensors

a construction method and image sensor technology, applied in the direction of semiconductor/solid-state device details, electrical devices, semiconductor devices, etc., can solve the problems of insufficient unsatisfactory reduction of light loss and optical crosstalk, and loss of incident ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

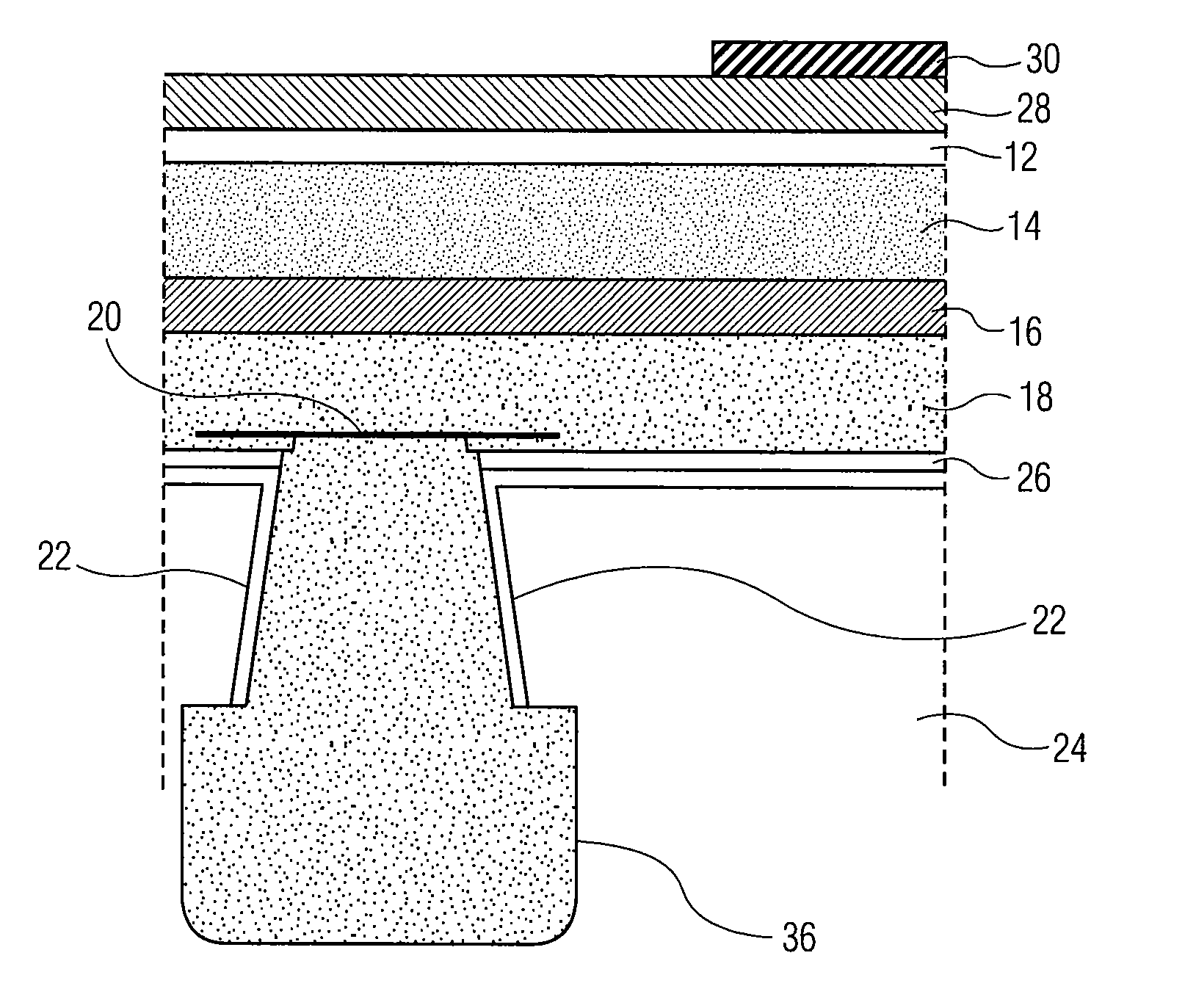

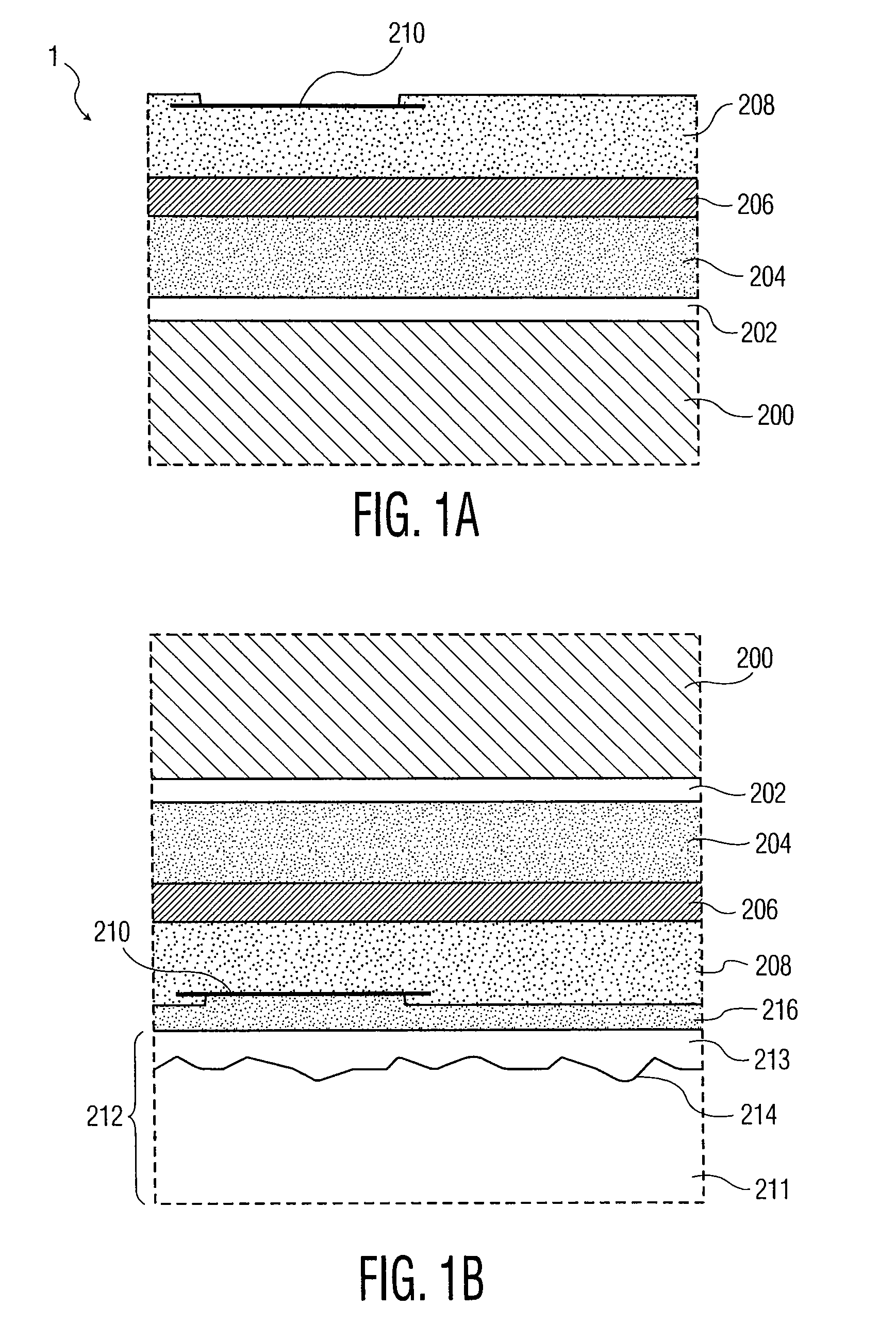

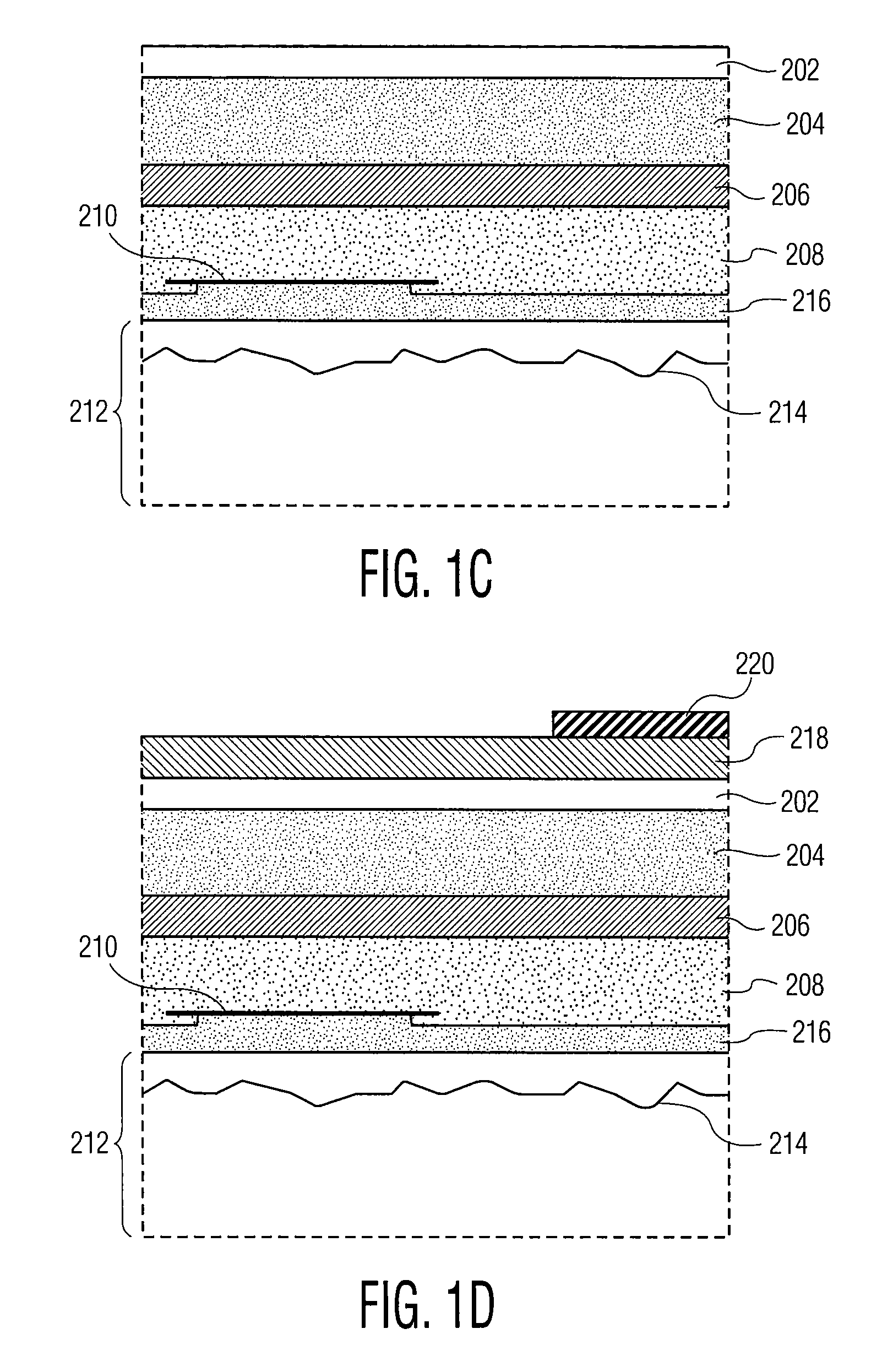

[0015]As described above, it may be necessary to thin the substrate of a backside illuminated imager to allow light to propagate through the substrate and to reach the photosensitive elements. For a silicon substrate, it may be desirable to thin the silicon to no more than a few microns, which is far below the minimum thickness required to provide mechanical integrity for wafer handling during processing. Accordingly, the embodiments of the present invention address construction methods for image sensors that provide mechanical integrity for wafer handling during processing and for high temperature processing to take place before color filters are placed.

[0016]FIGS. 1A-G and 2 illustrate steps in an example construction method for backside illuminated image sensors according to a first embodiment of the present invention. The first embodiment may include using a sacrificial handle wafer to provide mechanical stability for a semiconductor wafer during first processing steps and using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com