Method of fabricating a precast concrete meter pit

a precast concrete and meter pit technology, applied in the field of meter pits, can solve the problems of safety risk and inapplicability to use as a meter pi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

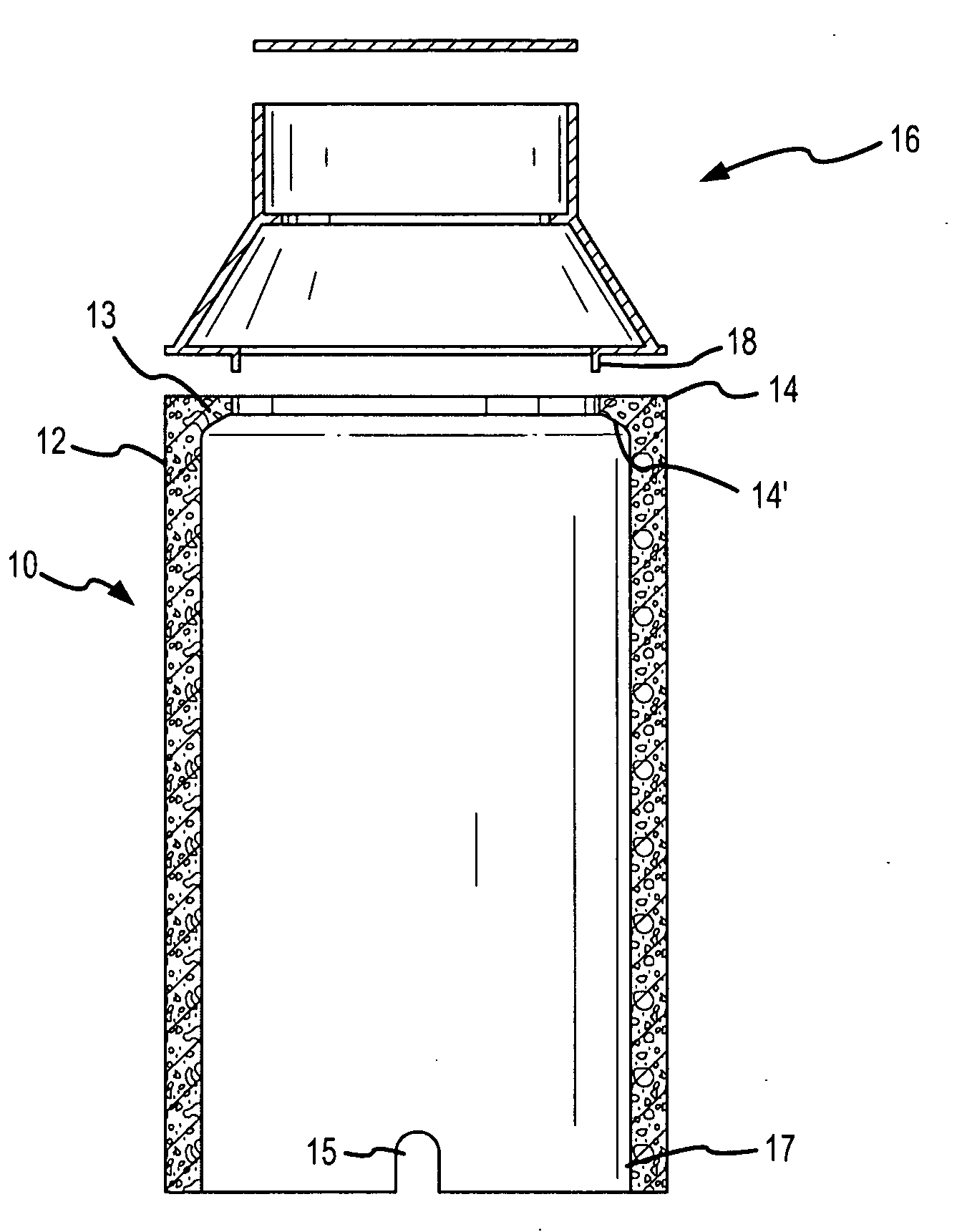

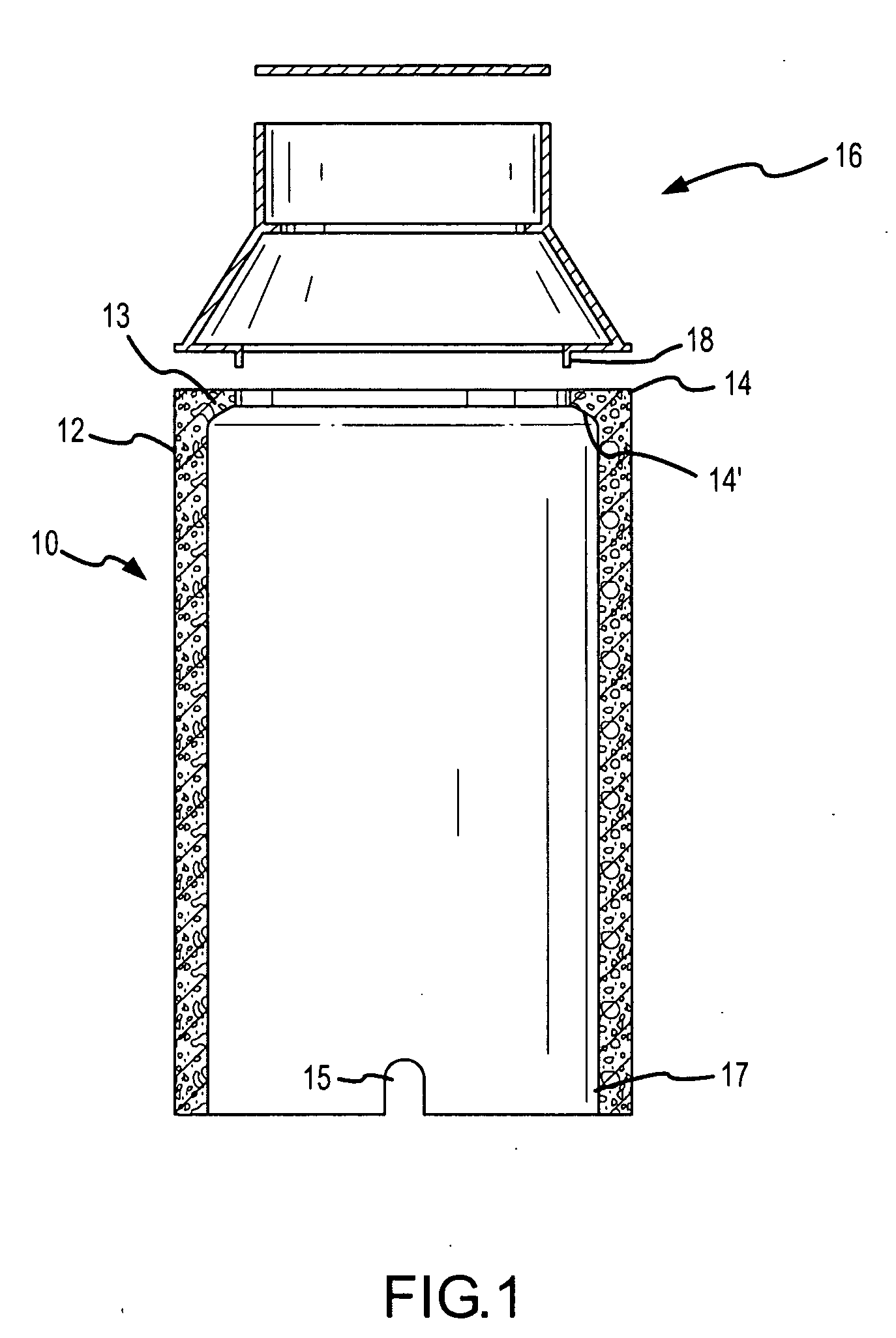

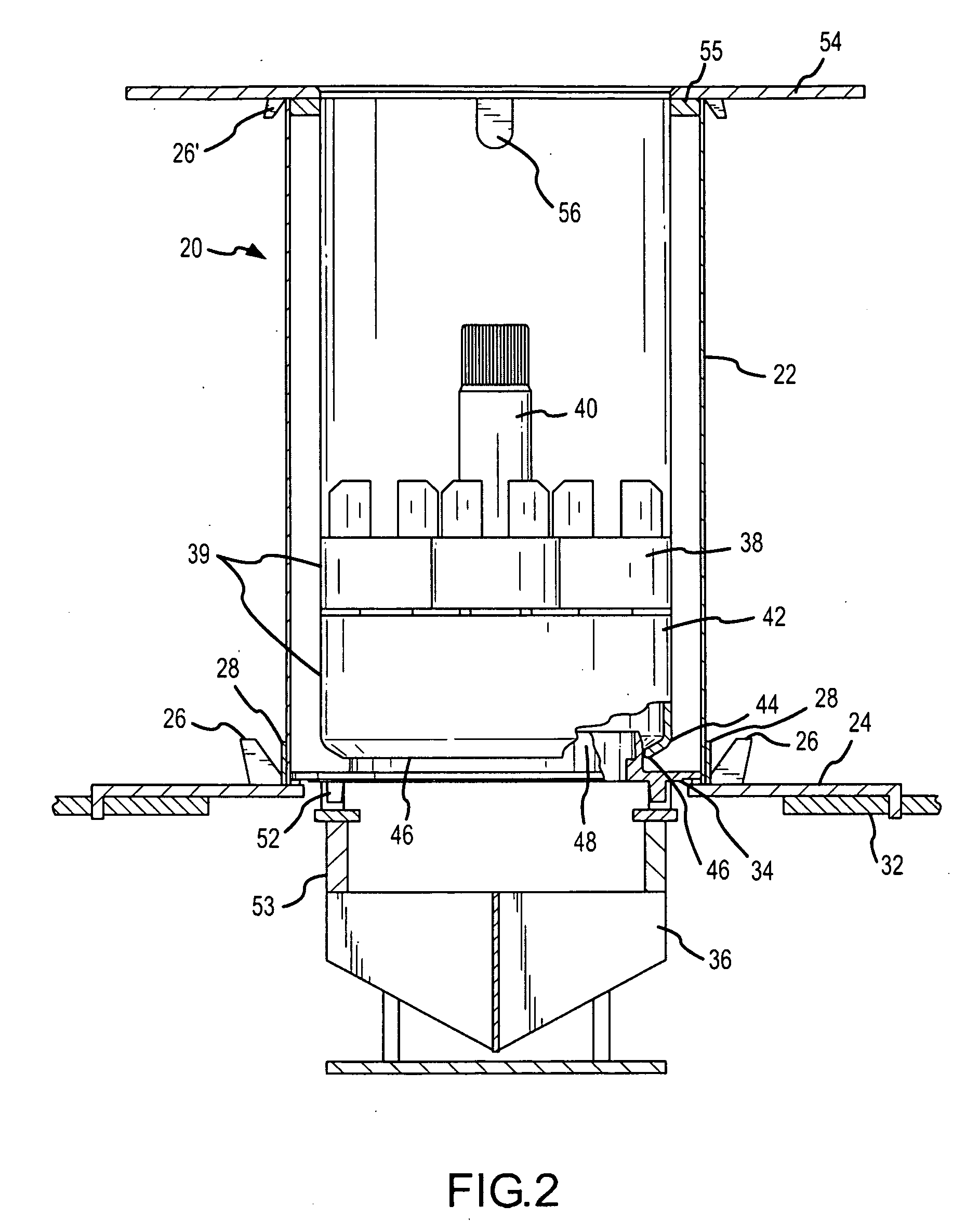

[0018]There is illustrated in FIG. 1a form of meter pit 10 for housing a water meter, not shown, beneath the ground. The meter pit 10 is comprised of an elongated precast concrete pipe 12 of cylindrical configuration and which is of uniform thickness throughout except for an upper end which terminates in a beveled edge 13 which defines a support ledge projecting radially inwardly from the upper terminal end 14. Dual spaced notches 15 are formed in an opposite lower edge 17 for receiving water lines, not shown. Although a single notch is illustrated, there is a diametrically opposed notch and which together receive the water lines for water flow into and out of the water meter which is housed inside of the pit.

[0019]The terminal end 14 of the beveled edge 13 is substantially flat and squared to the longitudinal axis of the pipe so as to form a ledge or seat for supporting a generally bell-shaped cover 16. The cover 16 is of standard construction including spaced projections or posts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gravity | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com