Blade opening arrowhead

a technology of arrowheads and blades, applied in the field of arrowhead opening arrowheads, can solve the problems of unfavorable aerodynamic steering of arrowheads, and achieve the effect of better cutting target materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

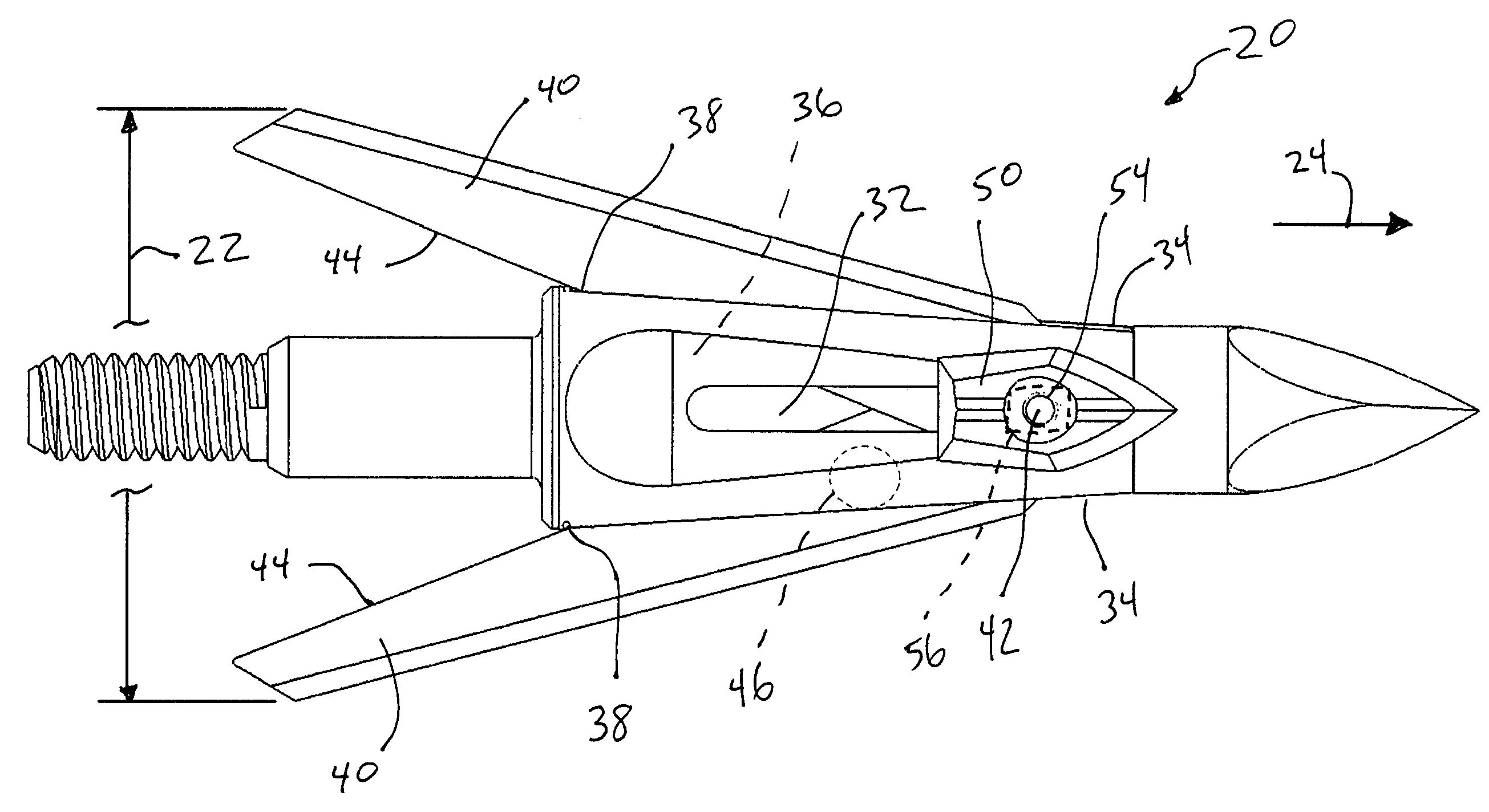

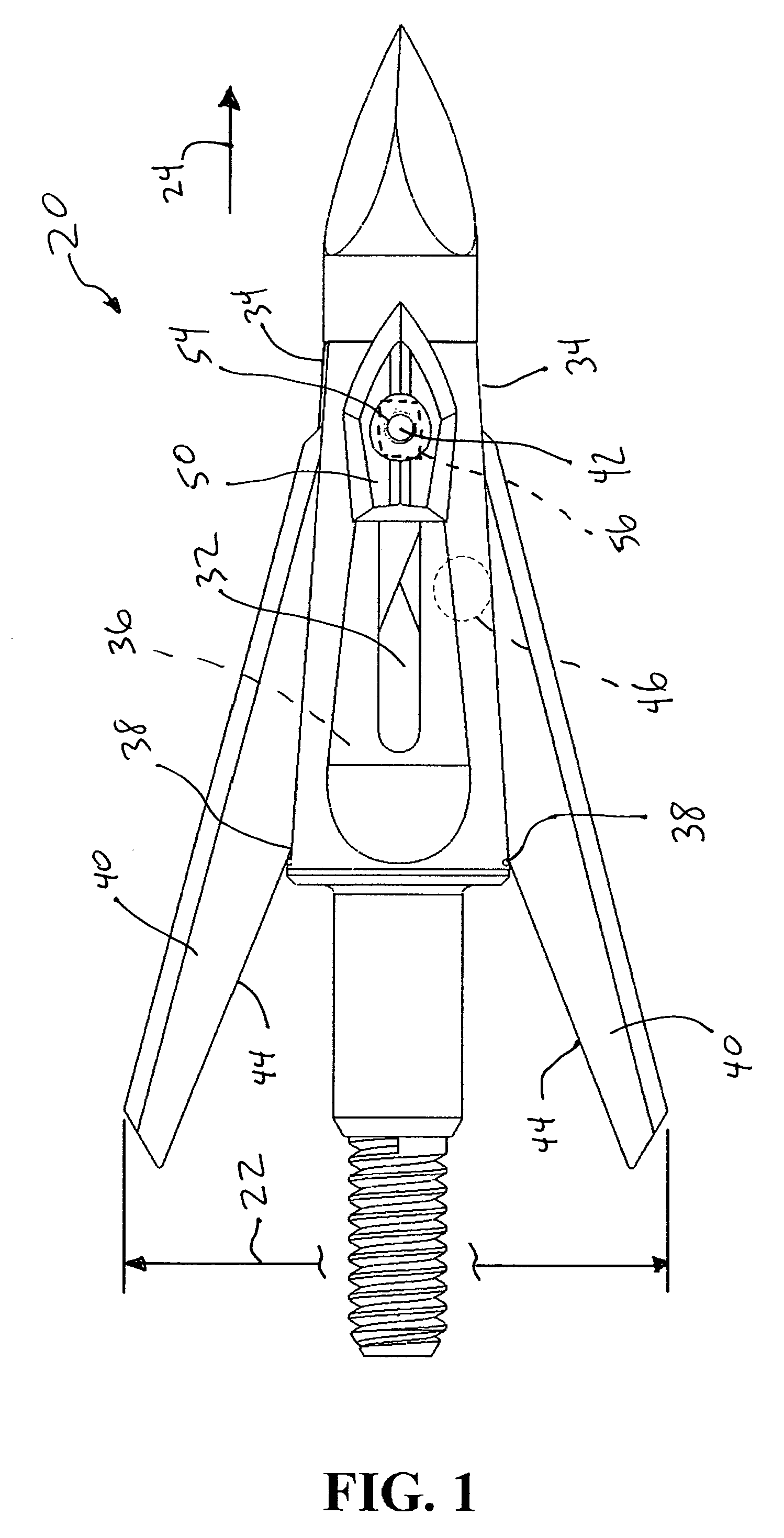

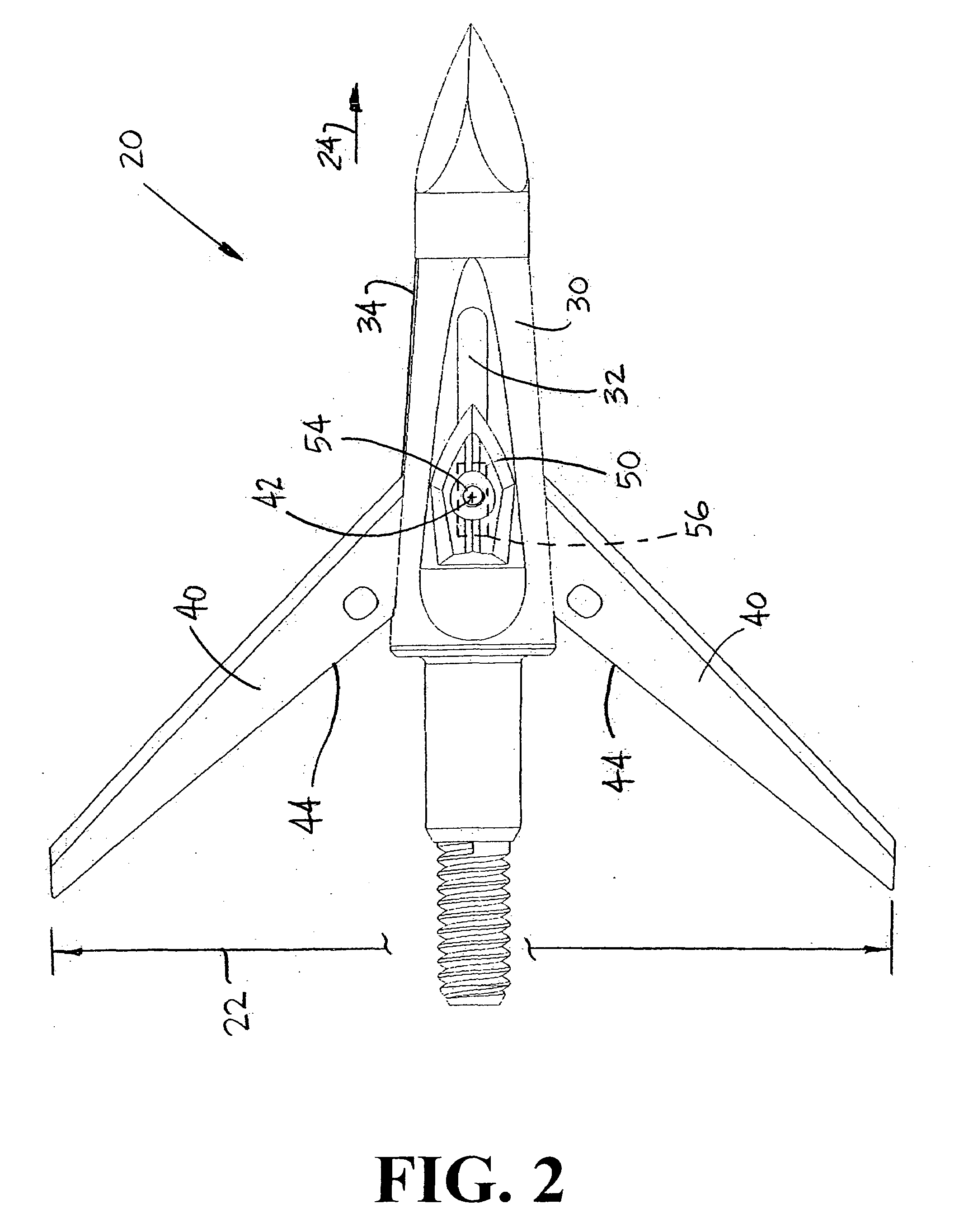

[0020]FIG. 1 shows arrowhead 20 in a closed position and FIG. 2 shows arrowhead 20 in an opened position, according to one embodiment of this invention. As shown in FIG. 2, cutting diameter 22 is greater in the opened position than cutting diameter 22 in the closed position, as shown in FIG. 1. A smaller cutting diameter 22 can result in better aerodynamic qualities and flight characteristics for the arrow.

[0021]Increasing cutting diameter 22 by moving blade 40 from the closed position to the opened position just before, after and / or simultaneously with target impact and / or penetration can provide arrowhead 20 with both relatively good in-flight characteristics and relatively good cutting characteristics, particularly when each blade 40 is opened to cutting diameter 22 as shown in FIG. 2.

[0022]FIG. 1 shows actuator 50 in a forward position. FIG. 2 shows actuator 50 in a rearward position. As shown in FIGS. 1 and 2, the forward and rearward directions are relative to a forward flight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com