Replaceable foundation vent

a technology of foundation vents and vents, which is applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of affecting the quality of construction, and consuming valuable construction time, and achieves the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

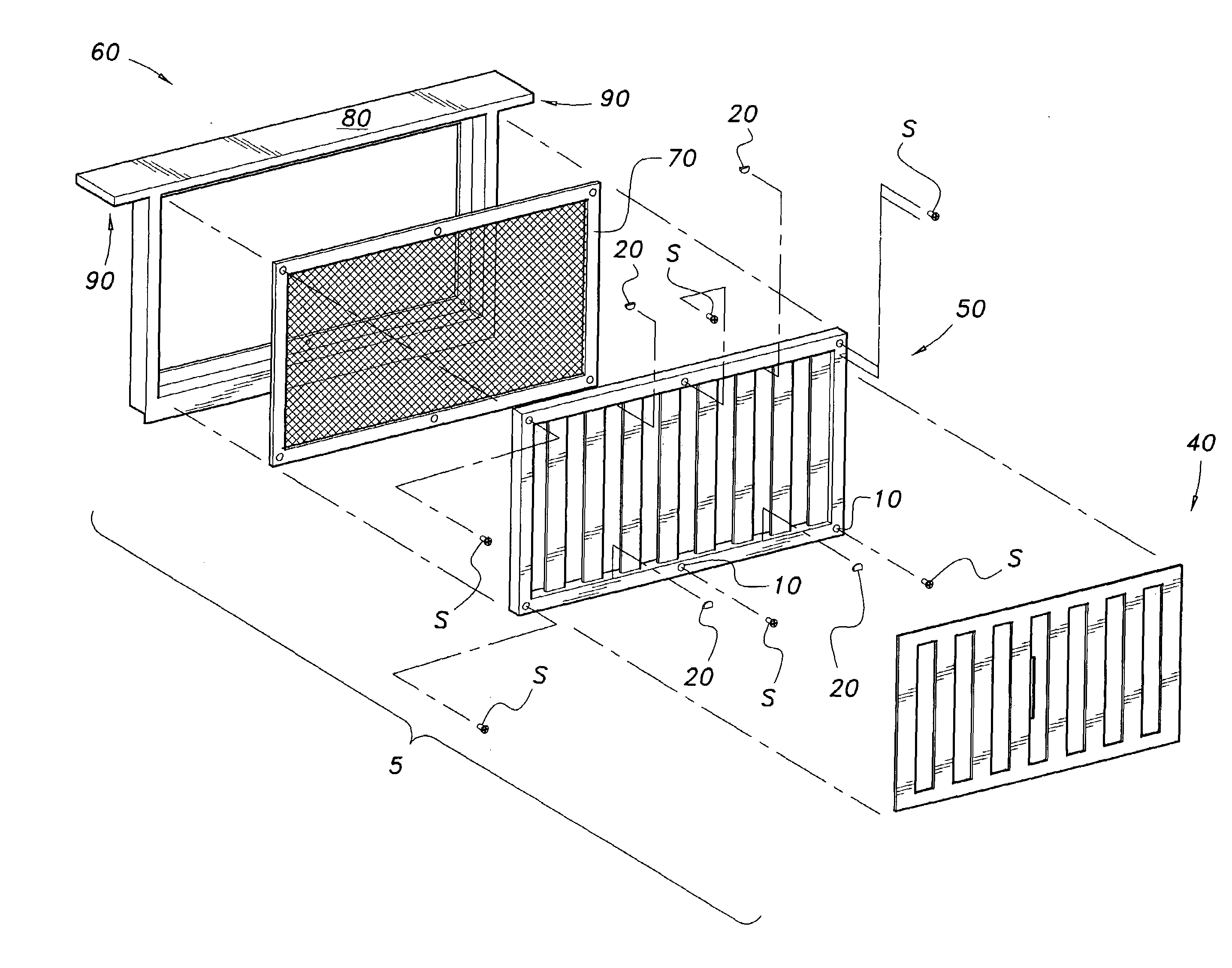

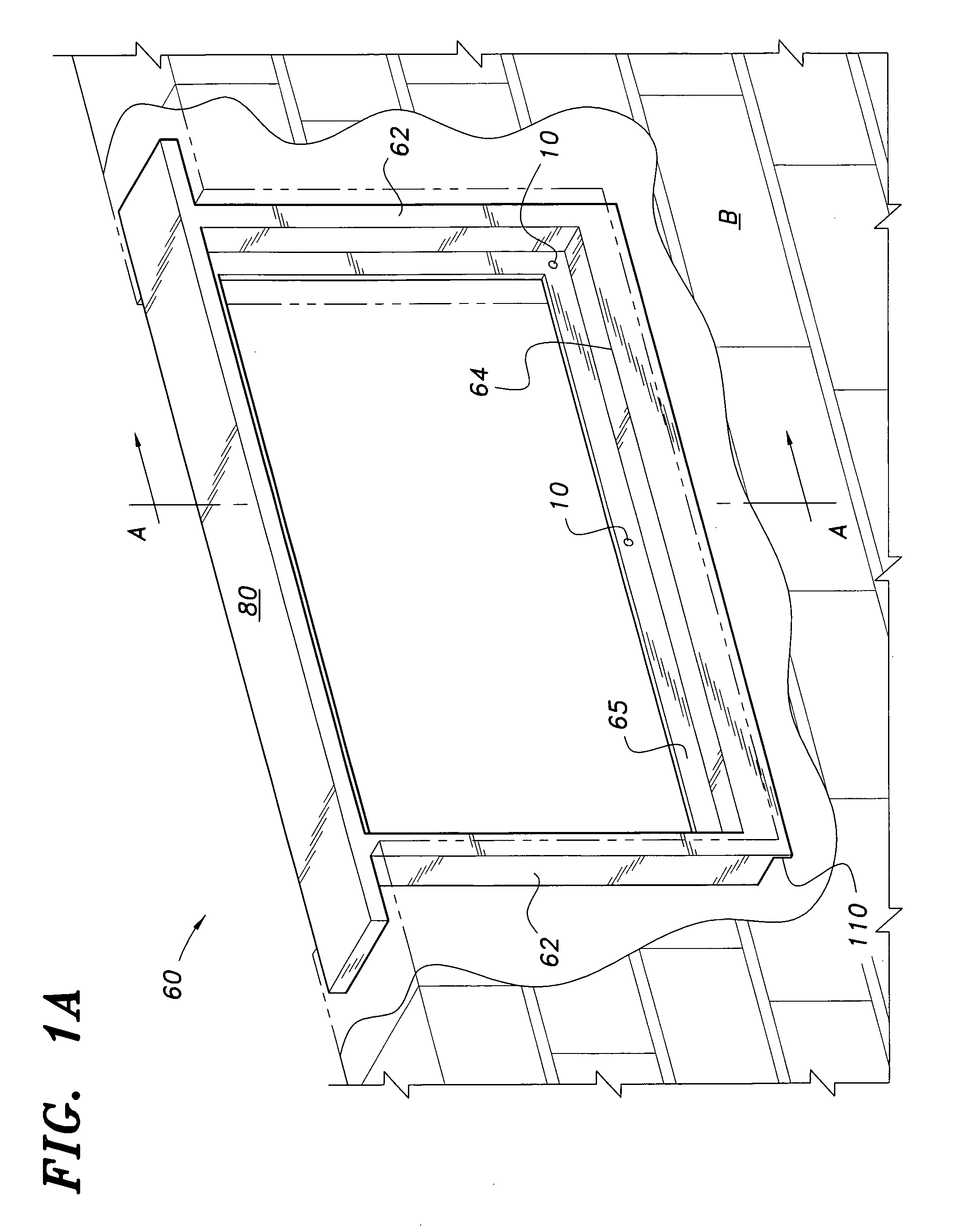

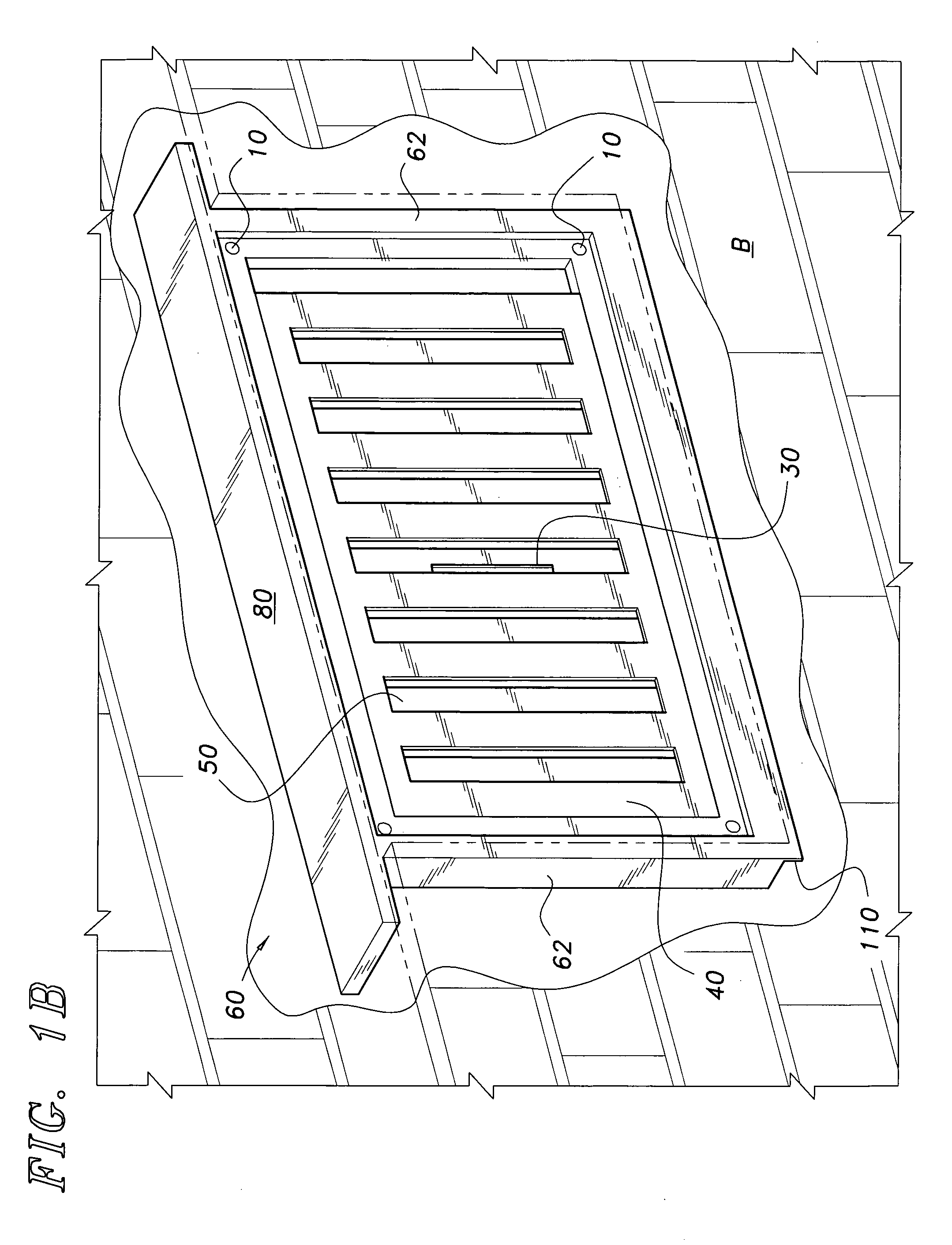

[0015]As shown in FIGS. 1A-3, the present invention relates to a replaceable foundation vent 5 that comprises a mounting frame 60, the mounting frame having respective opposing pairs of interconnected substantially horizontal and substantially vertical frame members defining a generally rectangular opening. Additionally, a plurality of vent components, including ventilation plate 50, slider panel 40, and screen 70, are removably attachable to the mounting frame 60 using fasteners, such as exemplary fasteners S. Fasteners S may be threaded, although unthreaded fasteners are also contemplated. As most clearly shown in FIGS. 1B and 2, the ventilation plate 50 and slider panel 40 are substantially rectangular, planar plates having complementary rectangular slots or gratings that allow for the regulation of airflow through the ventilation plate 50 as the slider panel 40 is slidably adjusted within the mounting frame 60. It should be understood, however, that the rectangular configuration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com