Skew rectification mechanism for fed paper

a skew and paper technology, applied in the direction of transportation and packaging, thin material processing, article separation, etc., can solve the problems of failure to achieve a micro-correction effect, difficult to smoothly deliver paper, and problems such as problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

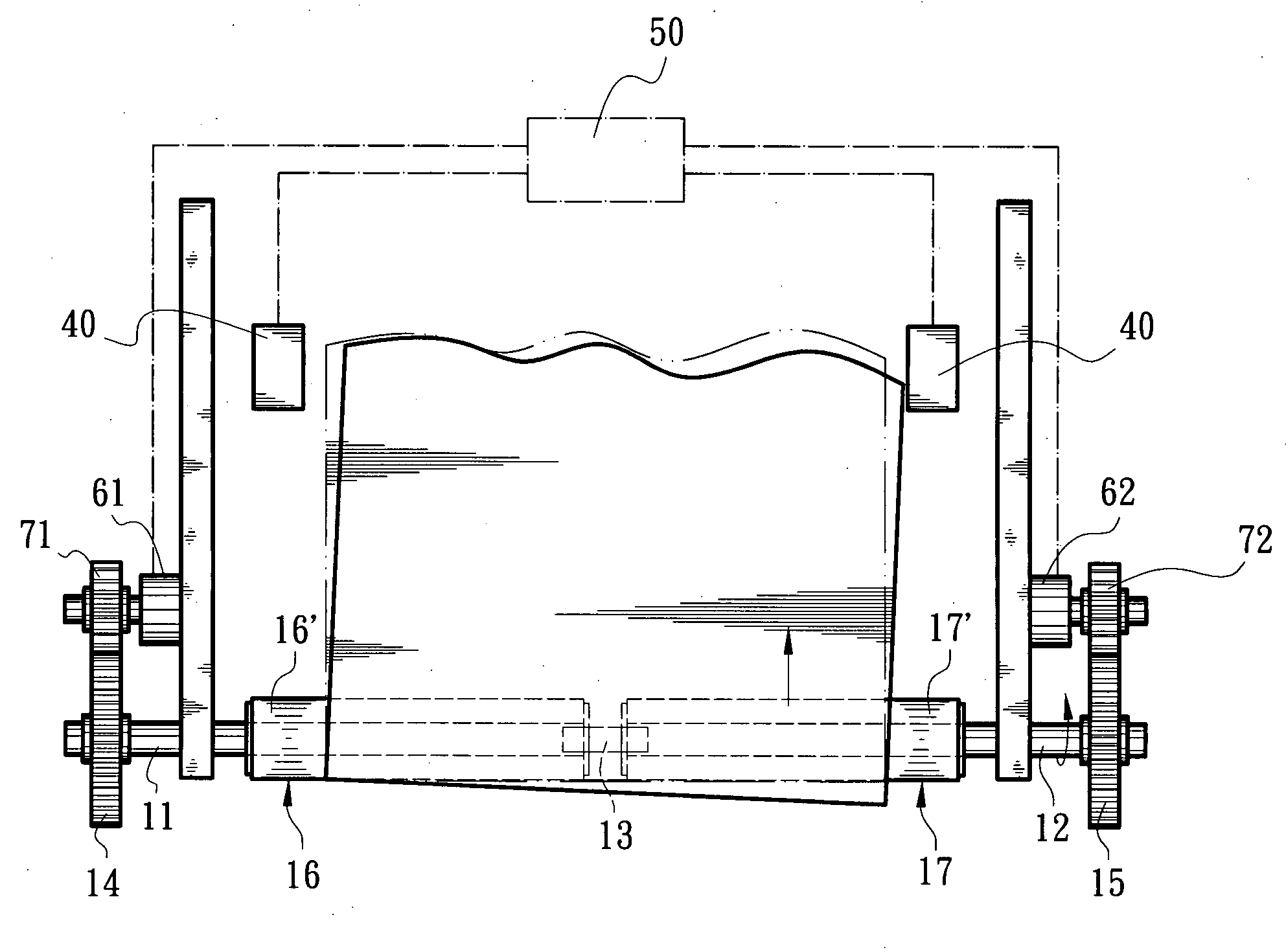

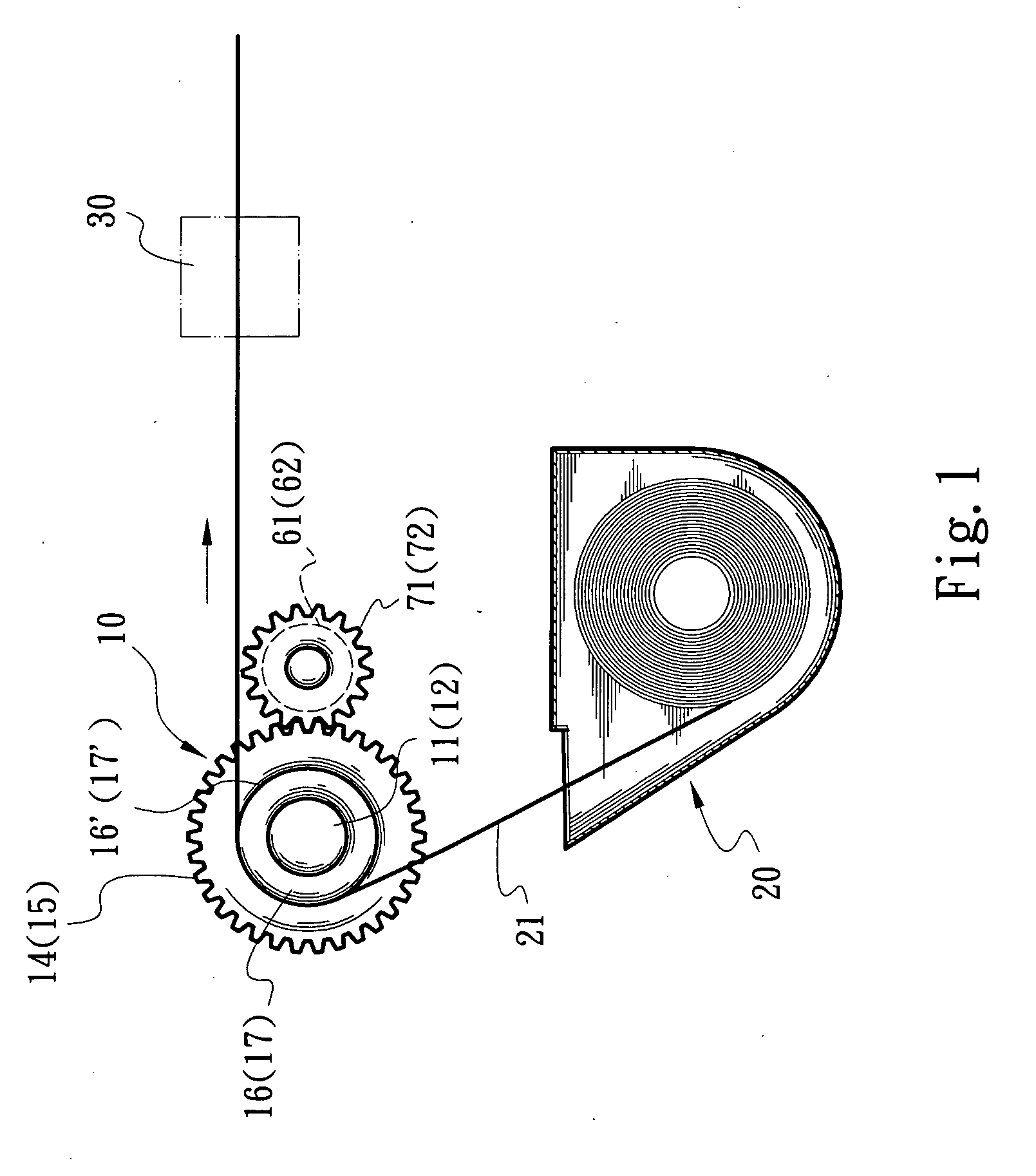

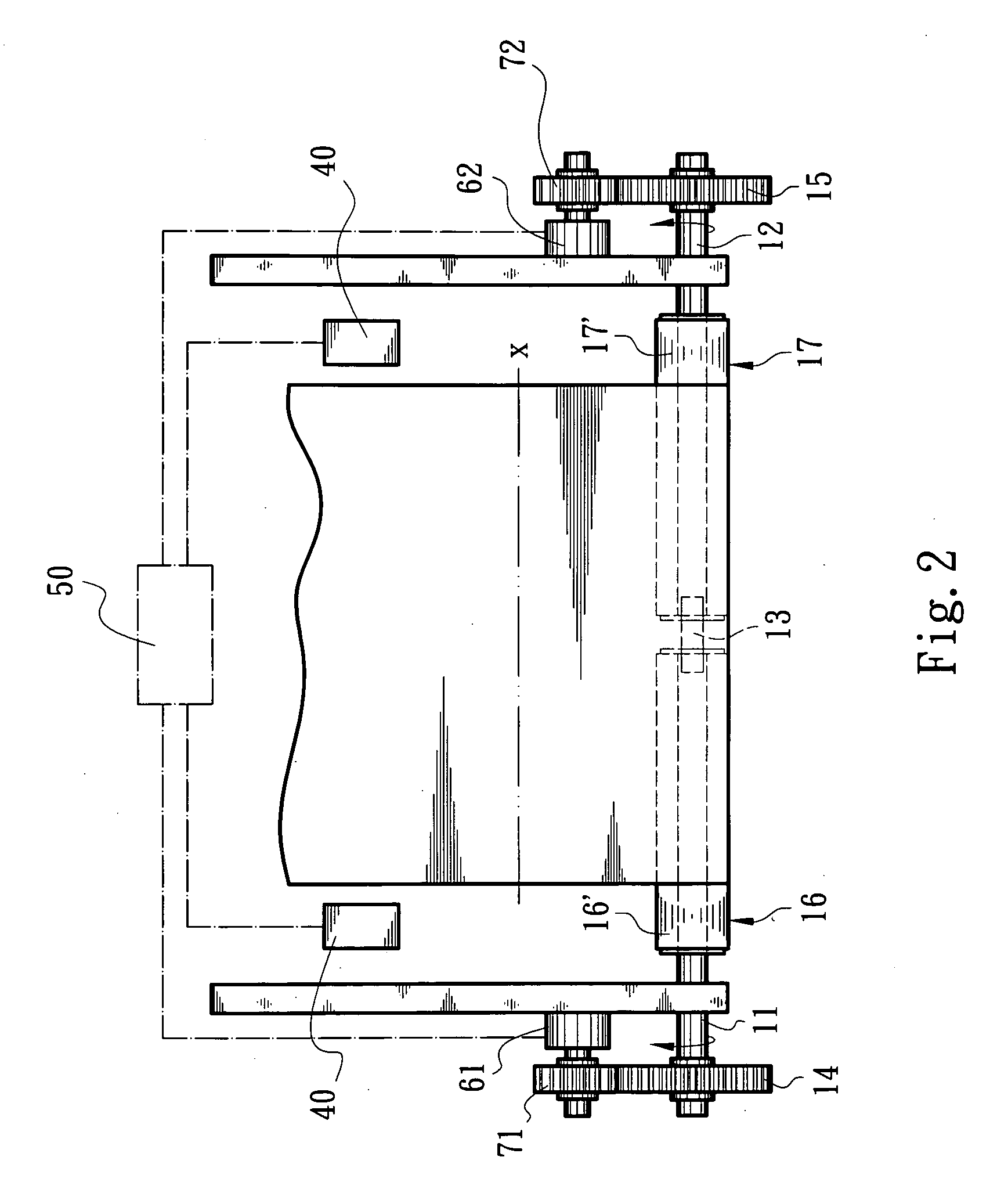

[0017]Please refer to FIGS. 1 and 2. The skew rectification mechanism for fed paper of the present invention includes a paper receptacle 20 in which a roll of paper 21 is contained, a recording section 30 for recording data or information on the paper 21 fed from the paper receptacle 20, and at least one detector 40 arranged in a position adjacent to a paper-feeding path for detecting the delivery condition of the paper 21 and transmitting detection signals to a control section 50. The control section 50 serves to controllably actuate motors 61, 62 to drive gears 71, 72. A guide section 10 is arranged between the paper receptacle 20 and the recording section 30 for guiding and delivering the paper 21.

[0018]The guide section 10 includes a first rotational shaft 11 and a second rotational shaft 12 coaxially interconnected with each other by a coupling shaft 13. The first and second rotational shafts 11, 12 are parallel to a transverse reference axis χ of the paper 21. The first and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com