Paper transportation device

a technology of transportation device and paper, which is applied in the direction of registering device, thin material handling, article separation, etc., can solve the problems of increasing wasted printed materials, difficulty in providing appropriate functions, and deterioration of printed materials, so as to save time and ensure the quality of printed materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

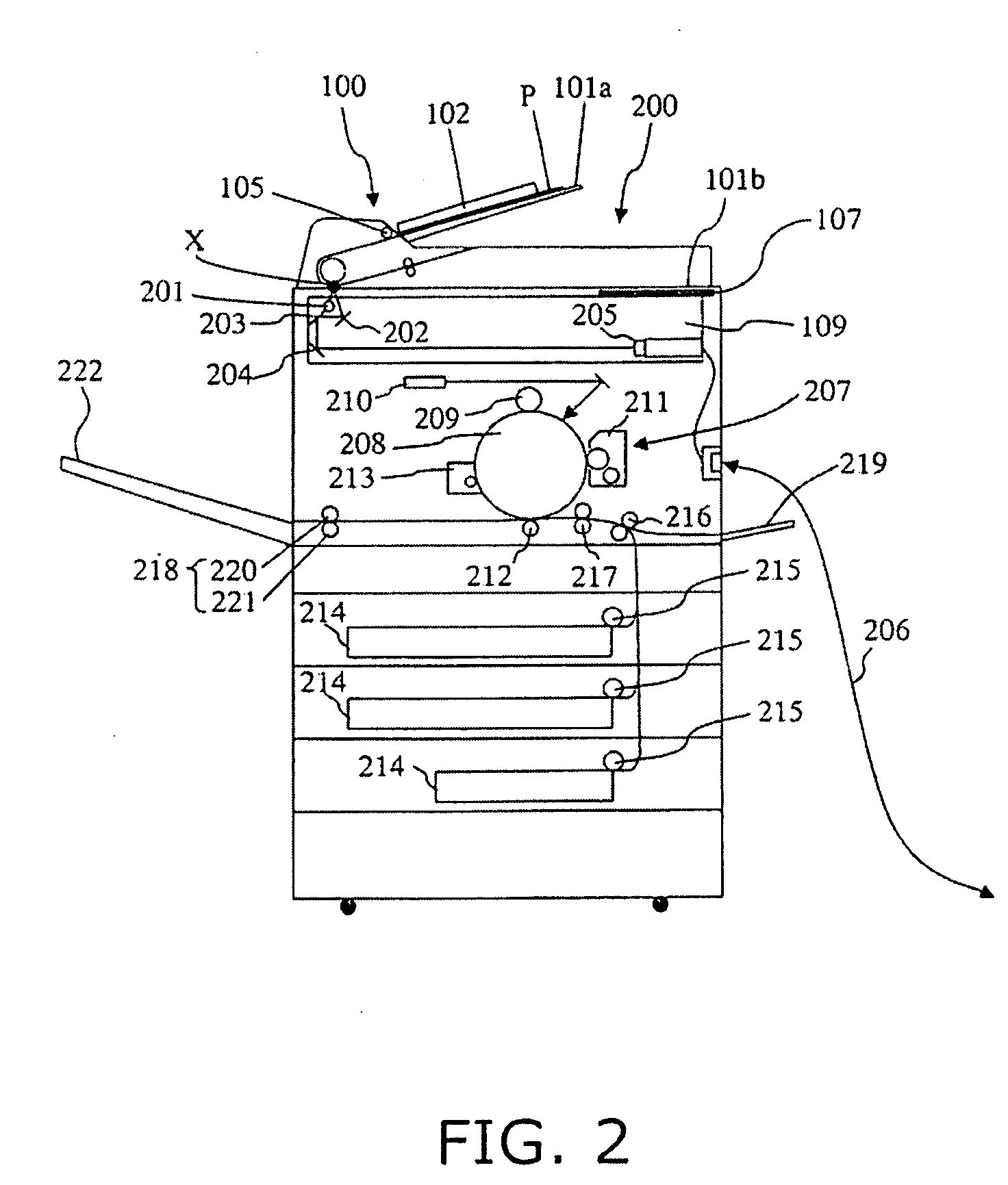

[0040]A paper transportation device of a first embodiment of the present invention is an automatic document feeder (ADF). The ADF is generally installed and used in an image forming apparatus. In the present embodiment, an ADF installed in an image forming apparatus will be hereinafter explained. In general, an image forming apparatus indicates a variety of apparatuses such as a printer, a scanner and a multifunction peripheral (MFP) having functions of a printer, a copier, a scanner, a facsimile machine, and the like. In the present embodiment, the image forming apparatus is configured to provide a user with a copy service, a scanner service, a facsimile service, a printer service and the like.

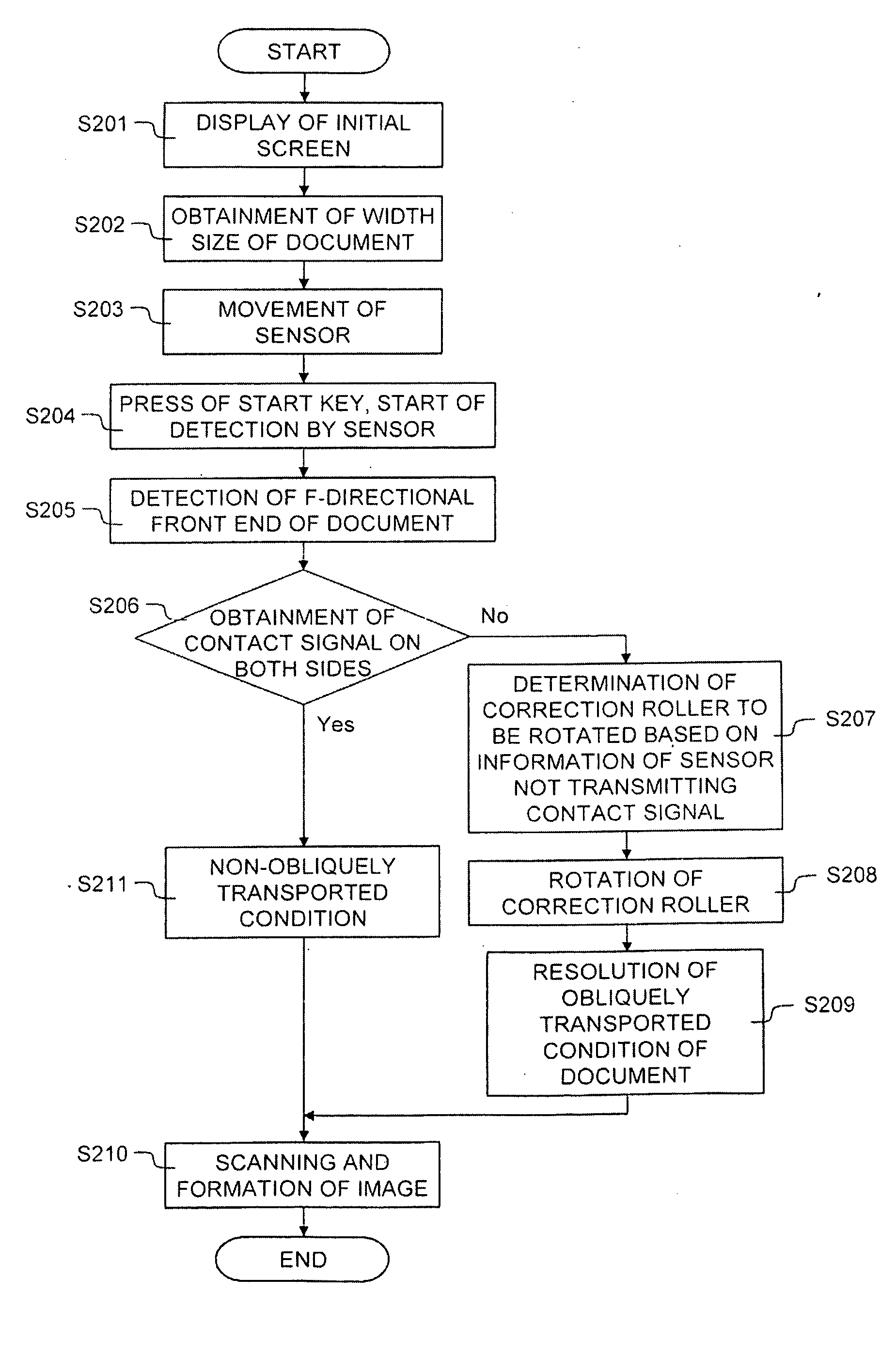

[0041]FIGS. 1A to 1C are views of schematic diagrams illustrating an ADF 100 and a disposition plate 101a of the first embodiment. Specifically, FIG. 1A illustrates a side view of the ADF 100. The ADF 100 includes the disposition plate 101a, a pair of alignment plates 102 (i.e., alignment pla...

second embodiment

[0090]A second embodiment will now be explained. In view of the similarity between the first and second embodiments, the parts of the second embodiment that are identical to the parts of the first embodiment will be given the same reference numerals as the parts of the first embodiment. Moreover, the descriptions of the parts of the second embodiment that are identical to the parts of the first embodiment may be omitted for the sake of brevity.

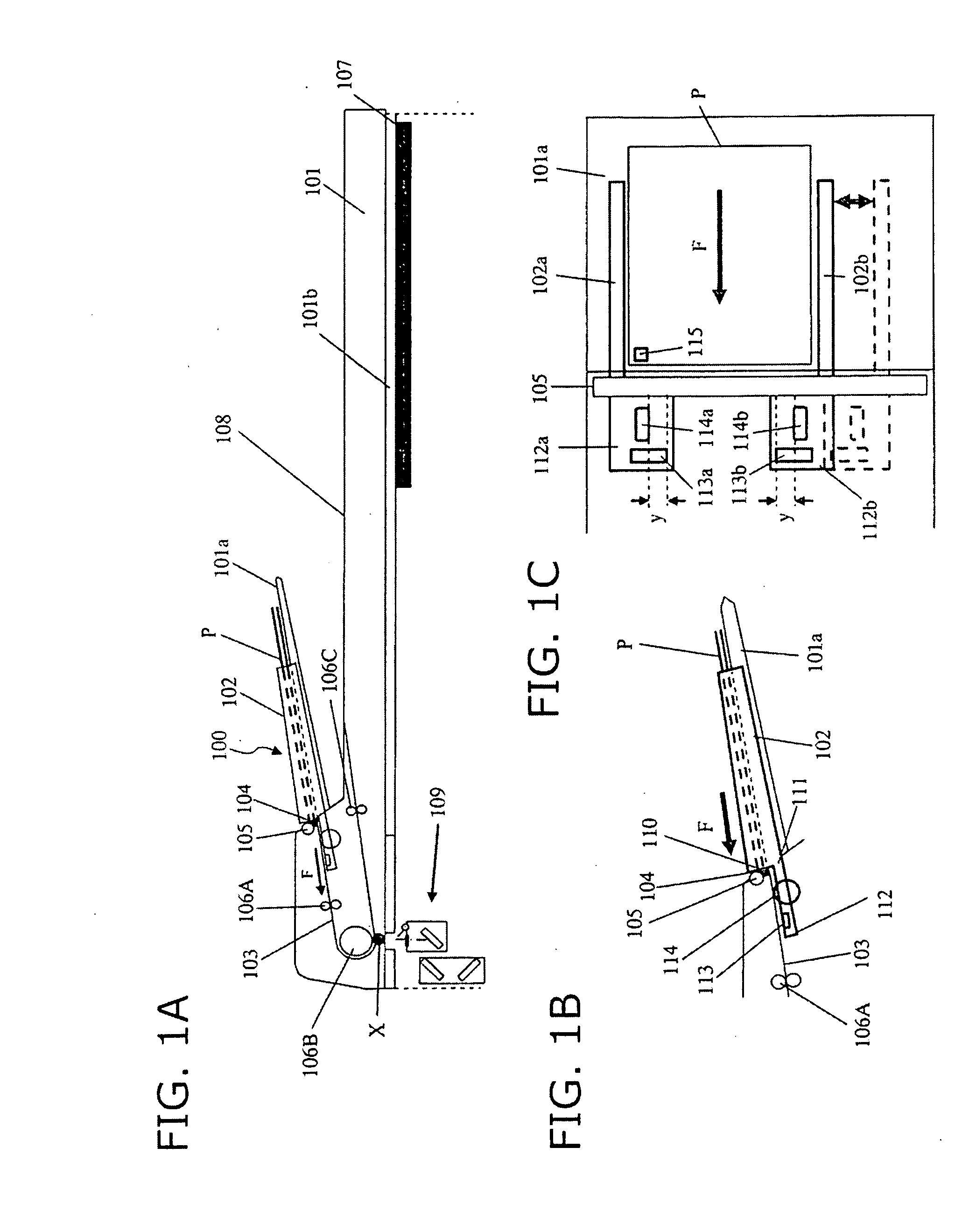

[0091]The following is an explanation of procedure executed by the ADF 100 and the MFP 200 of the second embodiment to detect accurately an obliquely transported condition of a sheet of document. The procedure will be explained with reference to FIGS. 8A, 8B, 9, 10, 11A and 11B. The second embodiment is primarily different from the first embodiment in that width size of the document is herein obtained and two obliquely transported condition detection sensors are moved in accordance with the obtained width size of the document. The first and se...

example

(m)

[0130]According to the second embodiment, the sensor movement controller is configured to adjust positions of the two sensors before the reception unit receives an input to set the copy function. However, the sensor movement controller may be configured to adjust their positions while the input is being received or after the input is received.

Example (n)

[0131]According to the first and second embodiments, the present invention is applied to the copy service. However, the present invention may be applied to any other suitable services such as a facsimile service, a scanner service, a printer service, a network scanning service and a post-processing service.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com