Heat dissipation module

a heat dissipation module and heat sink technology, applied in the direction of lighting and heating apparatus, basic electric elements, semiconductor devices, etc., can solve the problems of inability to significantly lower the cost and weight of the heat sink, and achieve the effect of enhancing heat transfer efficiency, reducing cost and weight, and effective cost and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

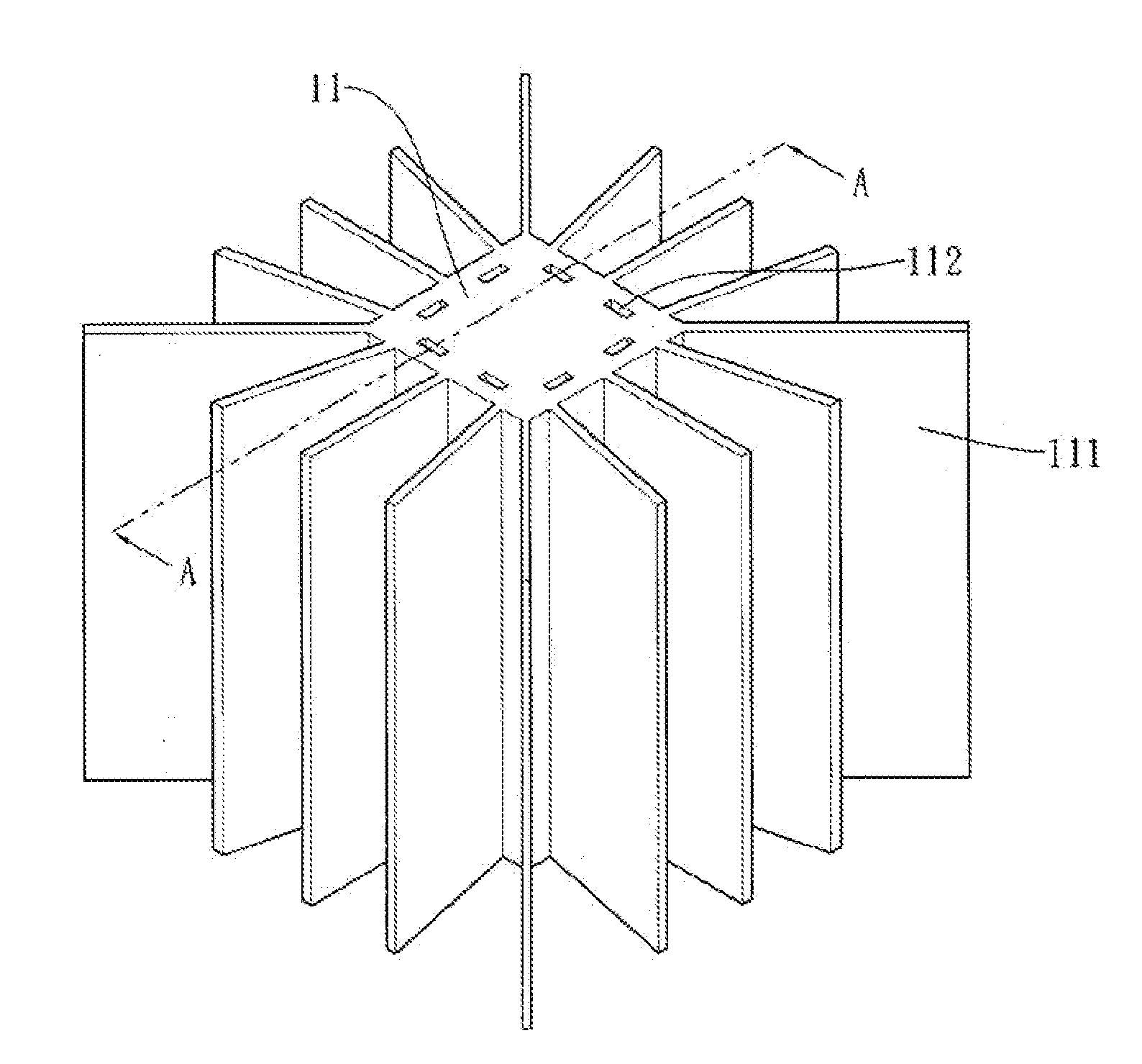

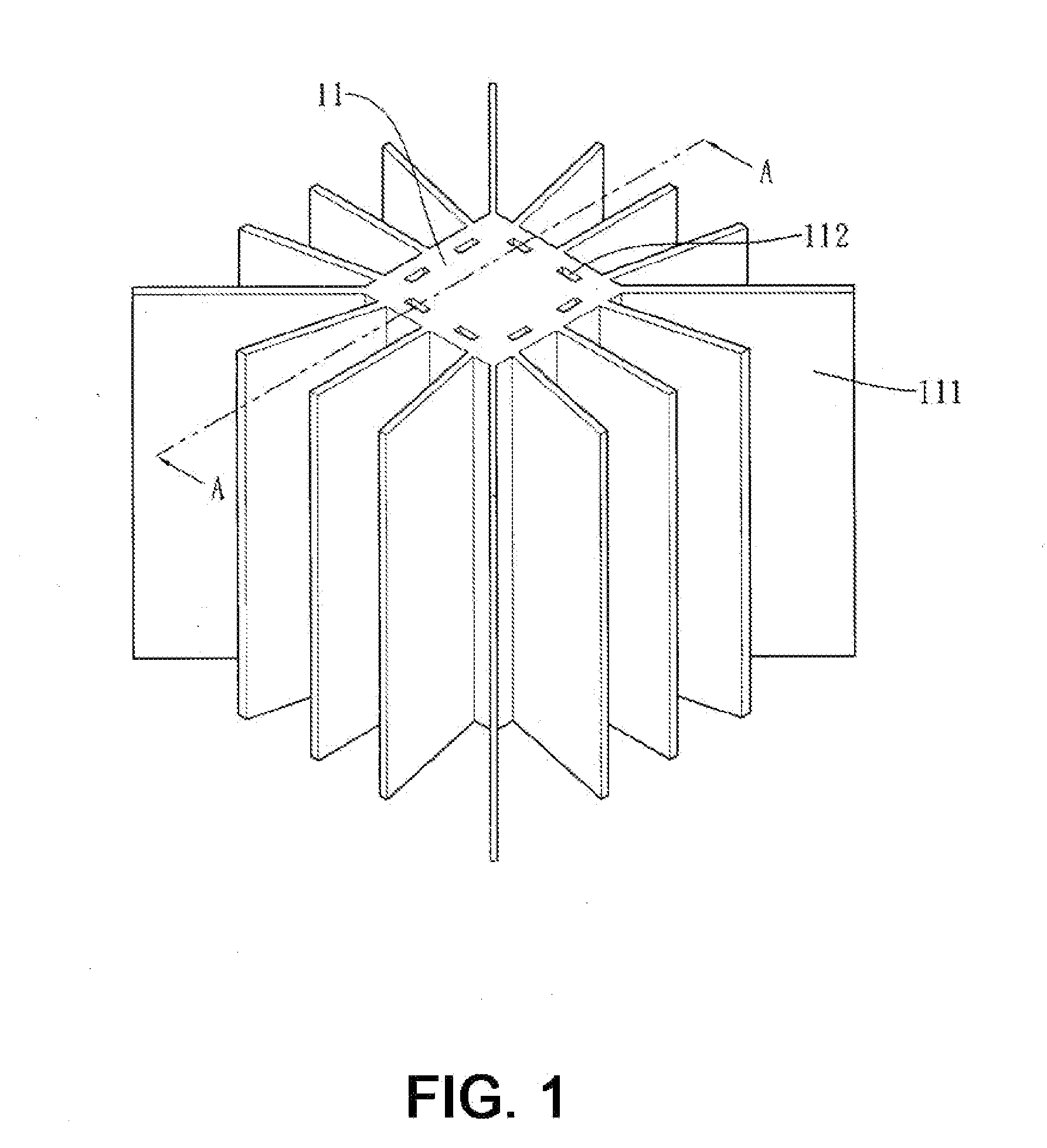

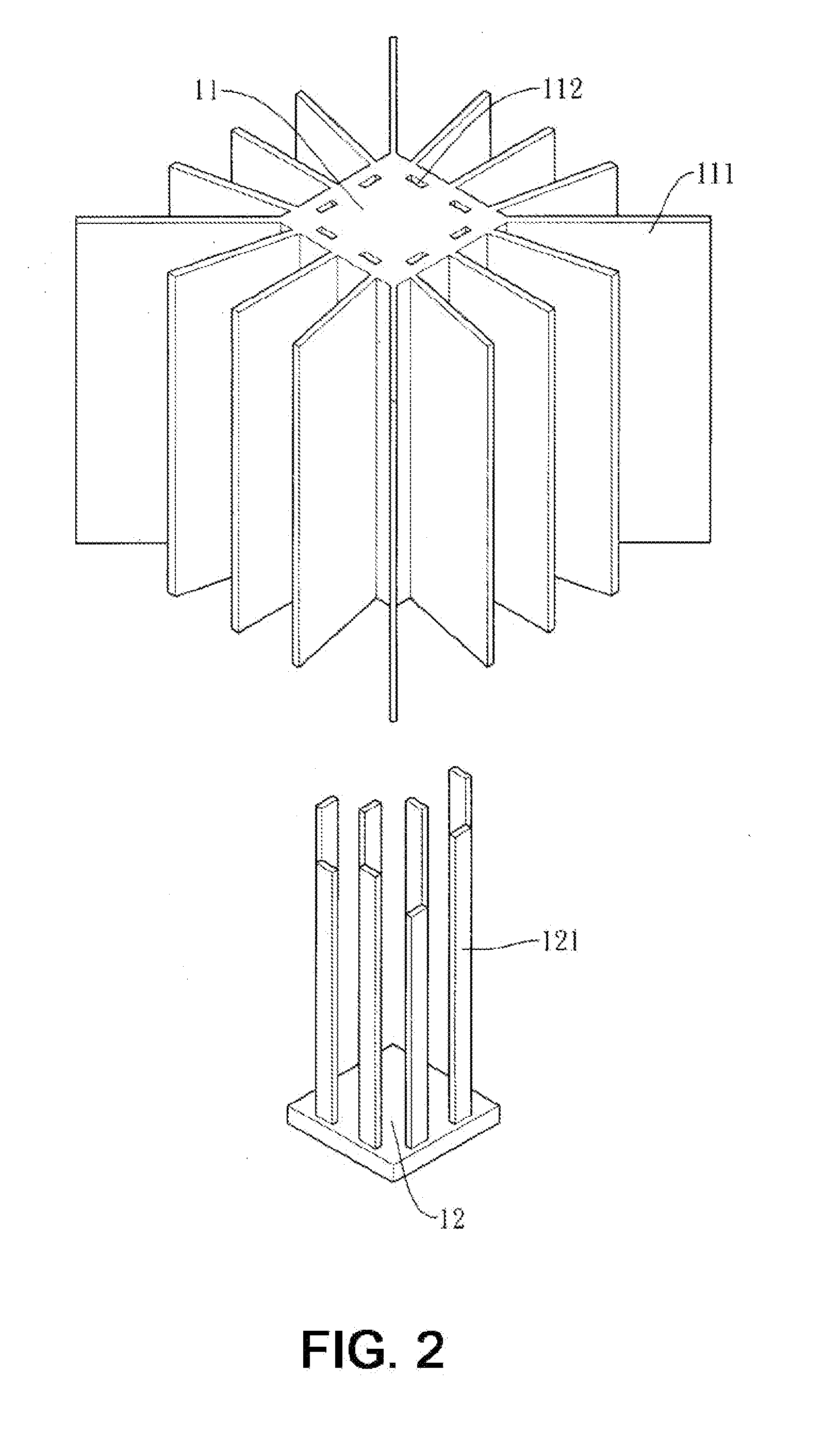

[0017]Referring to FIGS. 1 and 2, a heat dissipation module according to the present invention includes a rectangular cooling block 11 and a base 12. The cooling block 11 is made of aluminum and a plurality of fins 111 extend outward radially from the periphery of the cooling block 11. The bottom of the cooling block 11 has a central recess and at least an elongated through hole 112 pierces the cooling block 11 from the top to the bottom thereof. Further, the respective through hole 112 is parallel to the axial line of the cooling blocks 11. The through hole 112 has a rectangular-shaped periphery hole shown in FIGS. 1 and 2 and the respective rectangular through hole 112 is arranged to space apart from each other near the four sides of the cooling block 11.

[0018]The base 12, which is made of copper, is employed to fit with the central recess of the cooling block 11 and provides a plurality of elongated upright support legs 121 corresponding to the through holes 112. That is, the num...

second embodiment

[0020]Referring to FIGS. 4 and 5, the of a heat dissipation module according to the present invention is illustrated. The cooling block 21 is cylindrical and made of aluminum with a plurality of fins 211 extending outward radially from the circumferential side of the cooling block 11. The bottom of the cooling block 21 has a circular central recess and at least an elongated through hole 212 pierces the cooling block 21 from the top to the bottom thereof. Further, the respective through hole is parallel with the axial line of the cooling block 21. The respective through hole 212 has a circular periphery and is arranged in a way of spacing apart from each other near the circumferential side of the cooling block 11.

[0021]The base 22, which is made of copper, is employed to fit with the central recess of the cooling block 21 and provides a plurality of elongated upright circular support legs 221 corresponding to the through holes 212. That is, the number of the support legs 221 is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com