Cosmetic container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

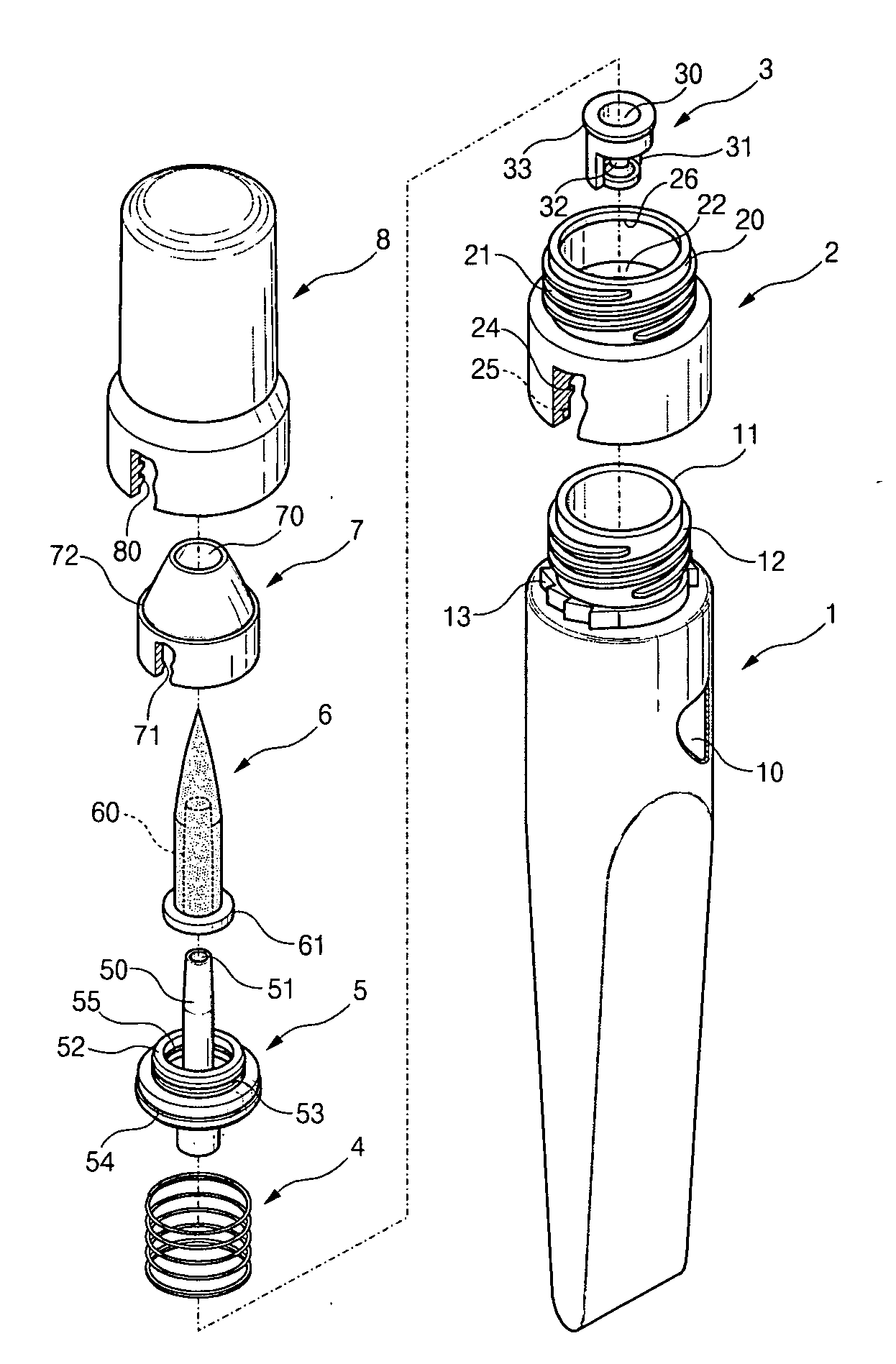

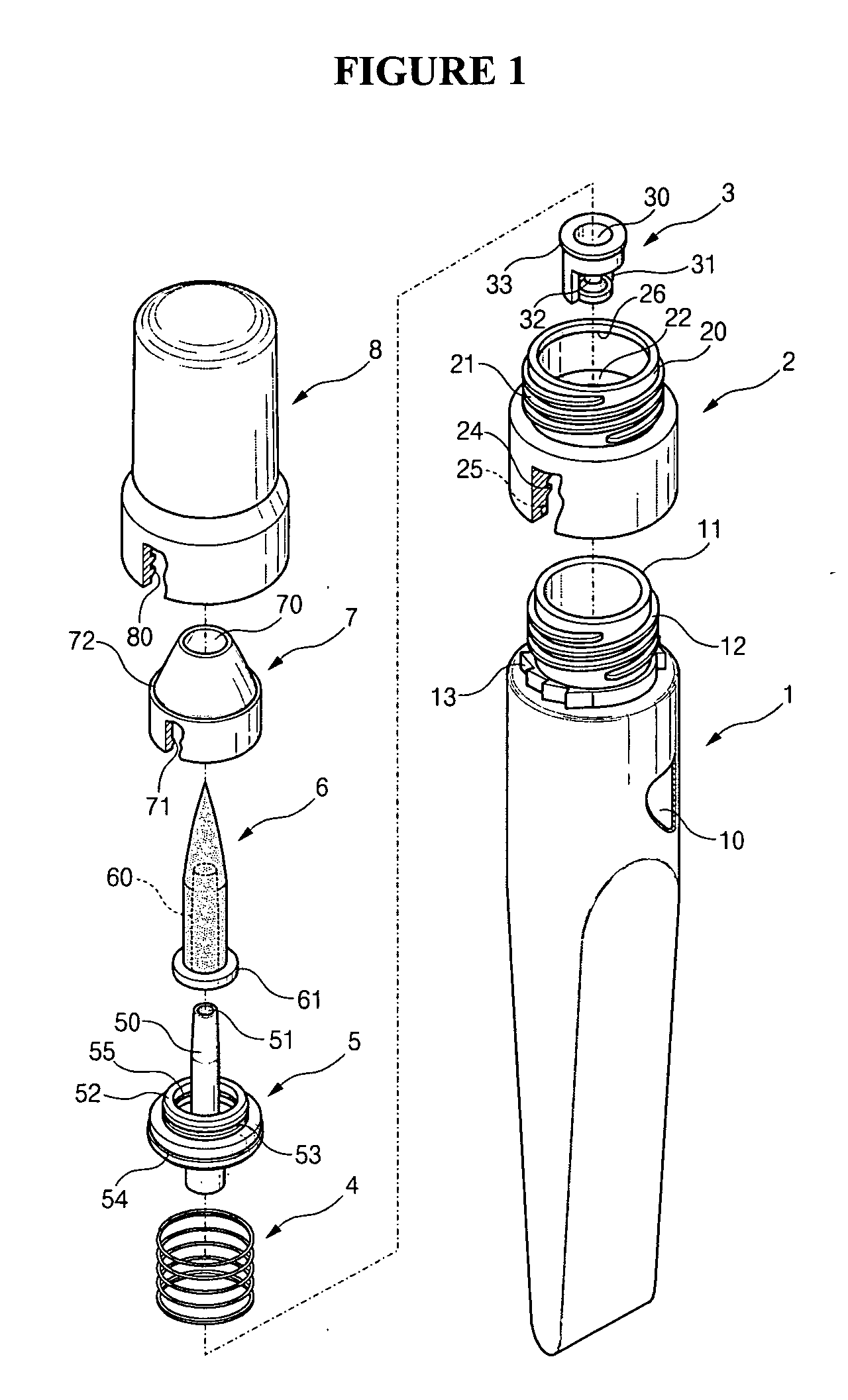

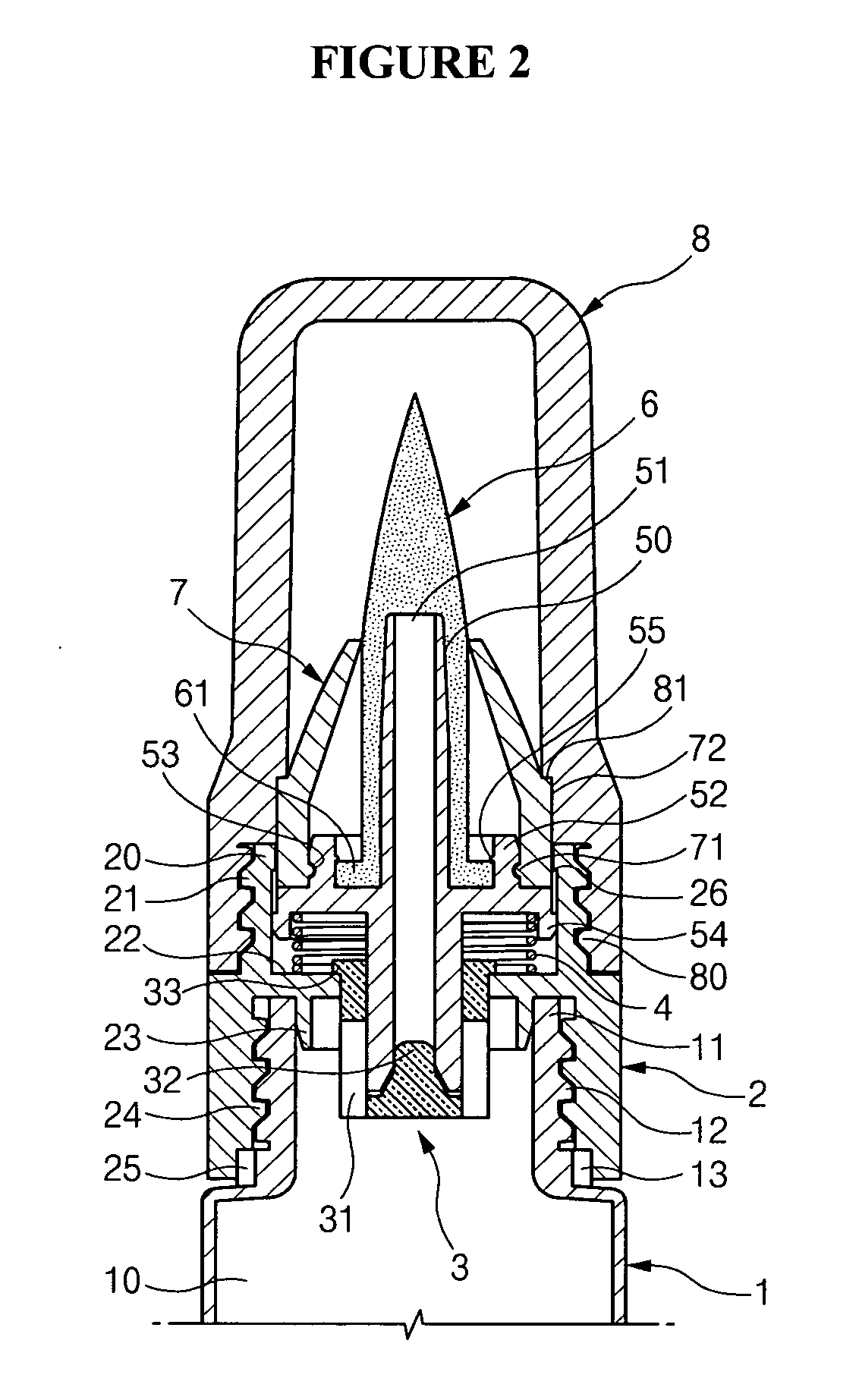

[0029]FIG. 1 is an exploded perspective view of a cosmetic container according to the present invention. The cosmetic container comprises a container body 1, a lower cap 2, a packing body 3, a spring 4, a lift cap 5, a brush 6, a brush cover 7, and an outer cap 8.

[0030]The packing body 3 is inserted into and integrally coupled to a hole formed at the center of the lower cap 2. The brush 6 is fitted around and integrally coupled to an axial tube 50 protruding upward from the center of the lift cap 5. After the brush 6 is coupled to the lift cap 5, the brush cover 7 is fitted over the lift cap 5.

[0031]The spring 4 is interposed between the lift cap 5 and the lower cap 2 with the packing body 3 coupled thereto, and the lift cap 5 is then coupled to an upper portion of the lower cap 2 so that it can be raised or lowered. When the lift cap 5 is raised or lowered, it serves as an opening / closing means for opening or closing an outlet 51 that is an outflow passage of a liquid cosmetic.

[003...

second embodiment

[0075]The lower cap 2 in the present invention is formed with a space 27 of a predetermined depth at the center of the recess 22 and an opening hole 28 at a side of a lower end of the space 27 so as to provide an outflow passage of a liquid cosmetic. An opening / closing protrusion 29 is formed to protrude from the center of a bottom surface defining the space 27 such that it can escape from or be inserted into the lower end of the axial tube 50 of the lift cap 5.

[0076]Here, the space 27 is formed to have a depth identical to that of the packing body 3 in the first embodiment of the present invention. Like the variant of the first embodiment shown in FIGS. 4 and 5, it is also possible to form opening holes 28 at both sides of the lower end of the space 27.

[0077]Since the method of opening and closing the outflow passage of the cosmetic container according to the second embodiment is identical to that of the first embodiment described above, a description thereof will be omitted.

[0078]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com