Direct shaft power measurements for rotating machinery

a technology of rotating machinery and power measurement, which is applied in the direction of instruments, magnetic bodies, sustainable buildings, etc., can solve the problems of calibration and environmental correction requirements, bandwidth limitations, and general low stability of gauges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]According to one embodiment, enhanced encoding systems for shafts and measuring properties thereof is achieved by sectional encoding where encoded zones or magnetic channels are generated in axial or circumferential directions of the shaft. For large diameter shafts, it is beneficial to employ this magnetic encoding where relevant flux densities can be achieved with lower encoding currents.

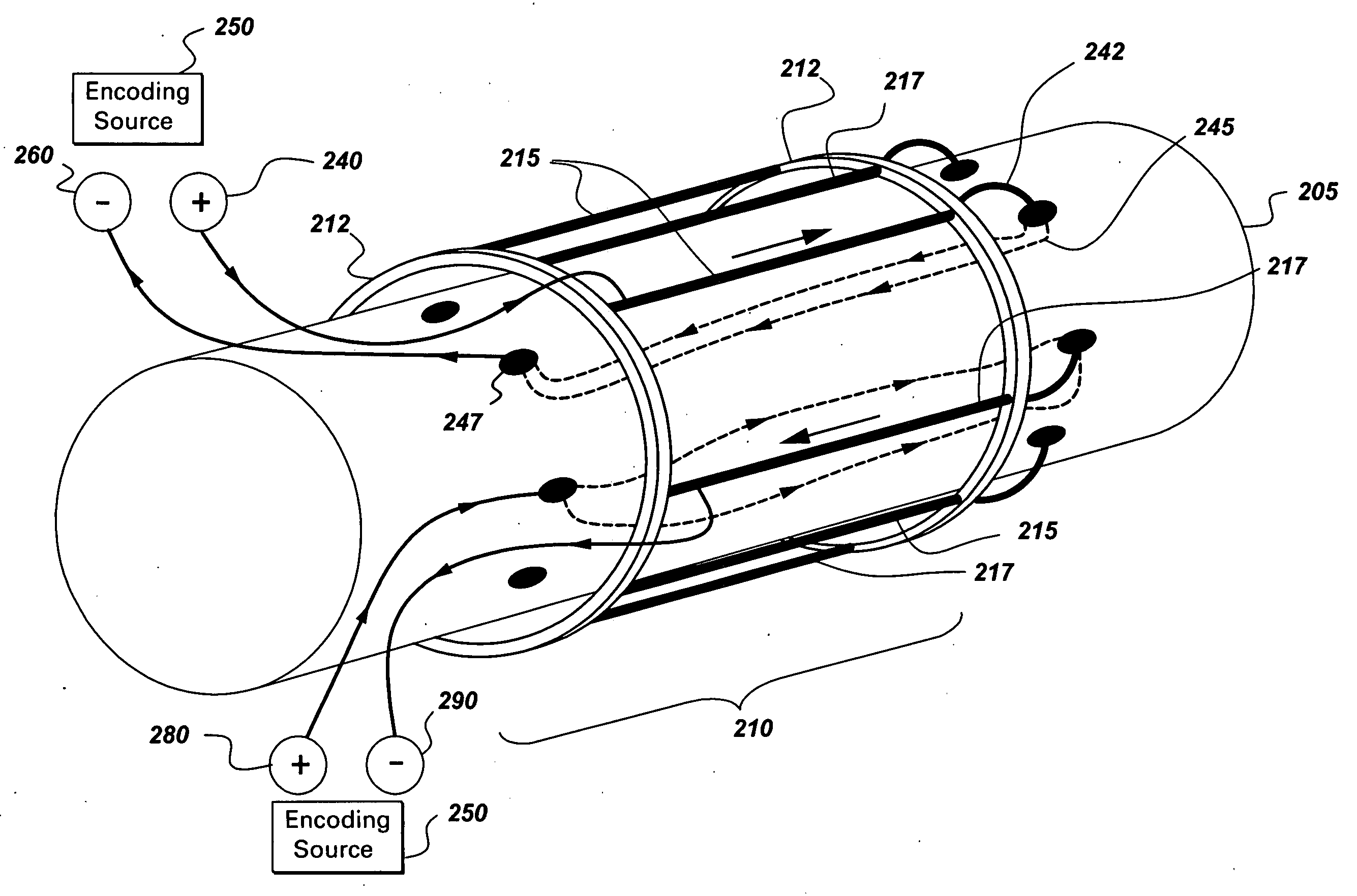

[0054]Referring to FIG. 2, encoding of magnetic polarized regions or channels according to one encoding embodiment is described. As previously noted, the shaft 205 can be a ferromagnetic material or have disposed upon it at least a section of ferromagnetic material affixed to the shaft. The encoding can be accomplished in a number of manners and one manner of operation disposes conducting members 215, 217 such as cables or metallic bars that are arranged about the shaft 205. As depicted, the conducting members 215, 217 extend along the shaft 205 longitudinally, although they may also extend ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| fall time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com